Blast furnace digital system implementation method based on computer simulation

A technology of computer simulation and system implementation, applied in the field of iron and steel metallurgy, can solve problems such as the inability to realize the digitization and visualization of the internal state of the blast furnace, the discontinuity of time and space scales, and the inability to describe the internal state of the blast furnace, so as to achieve outstanding substantive features and design Reliable principle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] An embodiment of the present invention provides a method for realizing a computer simulation-based blast furnace digitization system, including the following steps:

[0052] Step 1: Divide the blast furnace geometry in space, and set the boundary conditions and interfaces as the initialization conditions between the divided parts, where the blast furnace geometry in the spatially divided parts includes the furnace roof, the body, the convoluted area and the hearth ;

[0053] Step 2: Using the set interface conditions, the computer simulation method is used to simulate the state in the body of the blast furnace according to the continuous characteristics of the body and output the results;

[0054] Step 3: Aiming at the discrete characteristics of the furnace roof and the roundabout, use the partial results generated by the ontology simulation in step 2, and use the method of computer simulation to simulate the multiphase flow of the furnace top and the roundabout respec...

Embodiment 2

[0059] An embodiment of the present invention provides a method for realizing a computer simulation-based blast furnace digitization system, including the following steps:

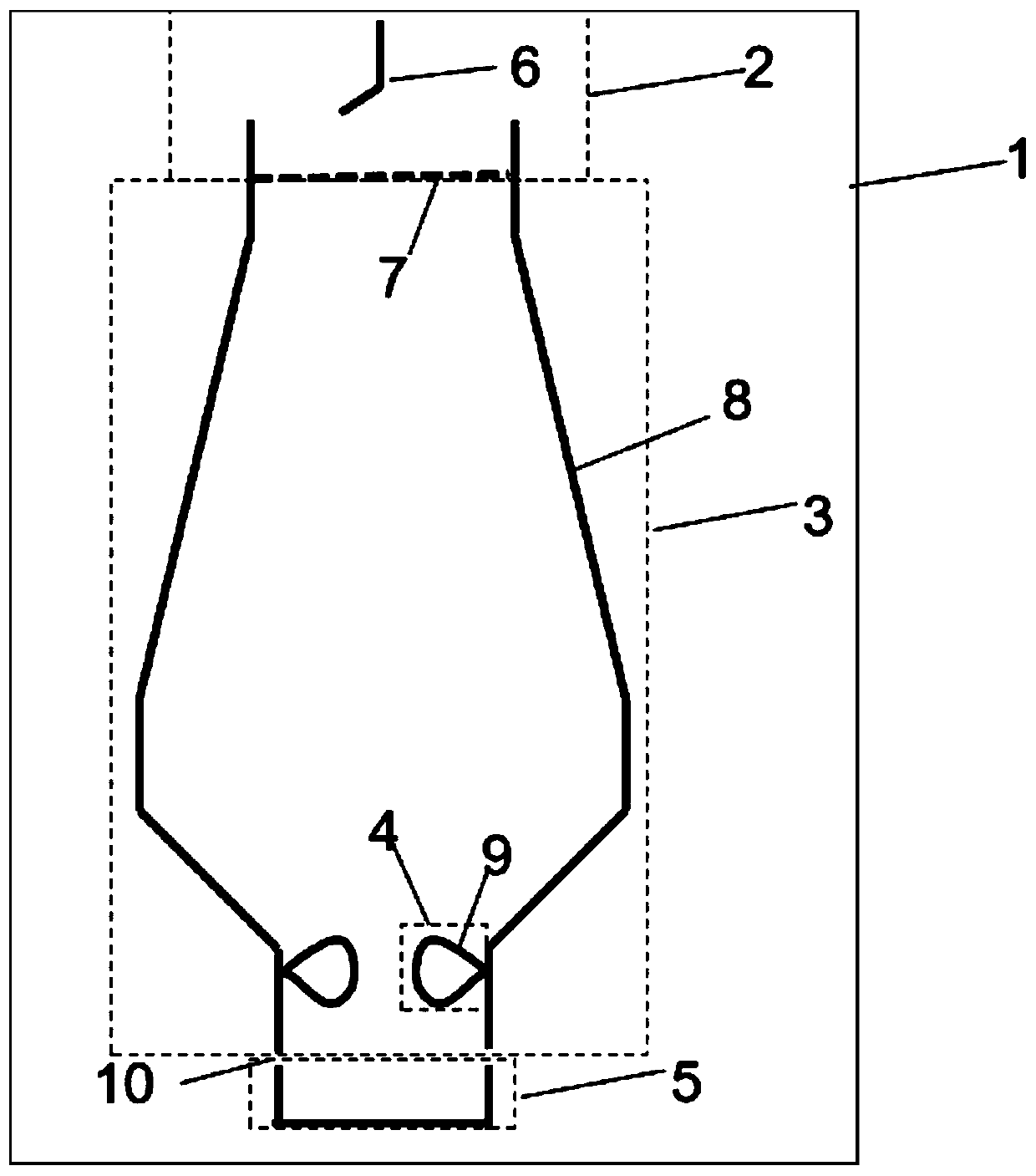

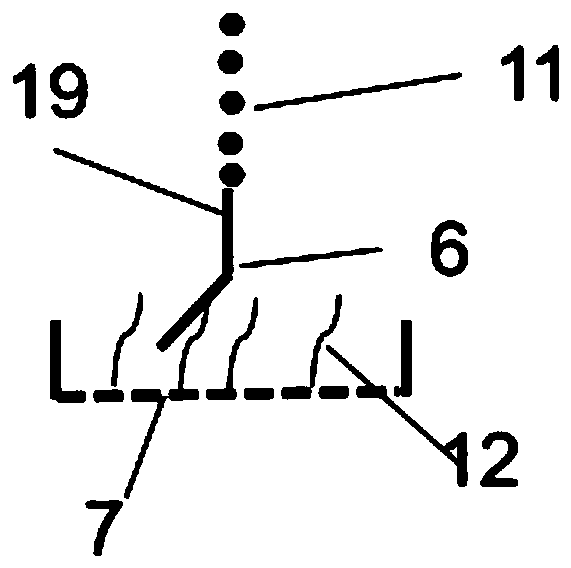

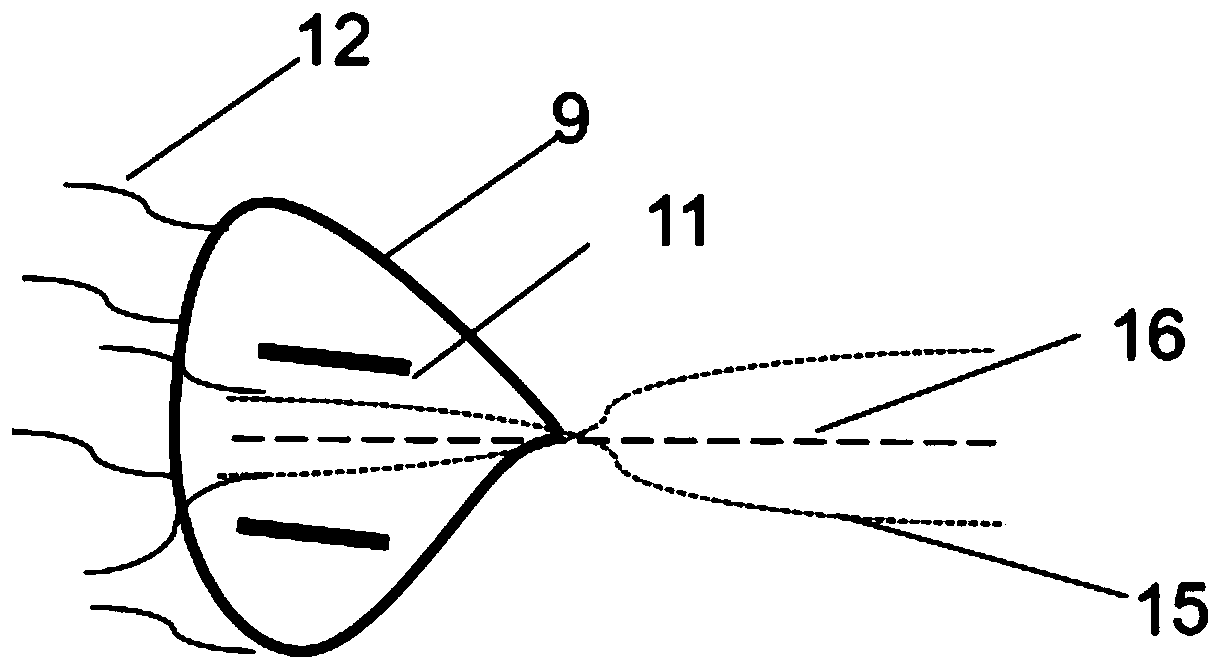

[0060] Step 1: Divide the blast furnace geometry in space, and set the boundary conditions and interfaces as the initialization conditions between the divided parts, such as figure 1 As shown, the blast furnace geometry is divided into four parts in space, including the furnace roof 2, the body 3, the convoluted area 4 and the hearth 5 from top to bottom, and the furnace roof 2 includes the part above the material level 7 of the blast furnace 1. The main body 3 includes the portion below the charge level 7 of the blast furnace 1 to the plane of the taphole 10 , and does not include the portion within the boundary 9 of the turning zone. The swirl zone 4 includes the part within the swirl zone boundary 9 of the blast furnace 1 . The hearth 5 includes the portion below the taphole 10 of the blast furnace 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com