High-safety spent fuel storage grillwork

A storage grid, high-security technology, applied in the field of high-security spent fuel storage grid, can solve problems such as insufficient removal of spent fuel assemblies, deterioration of cooling conditions, meltdown, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the drawings and embodiments.

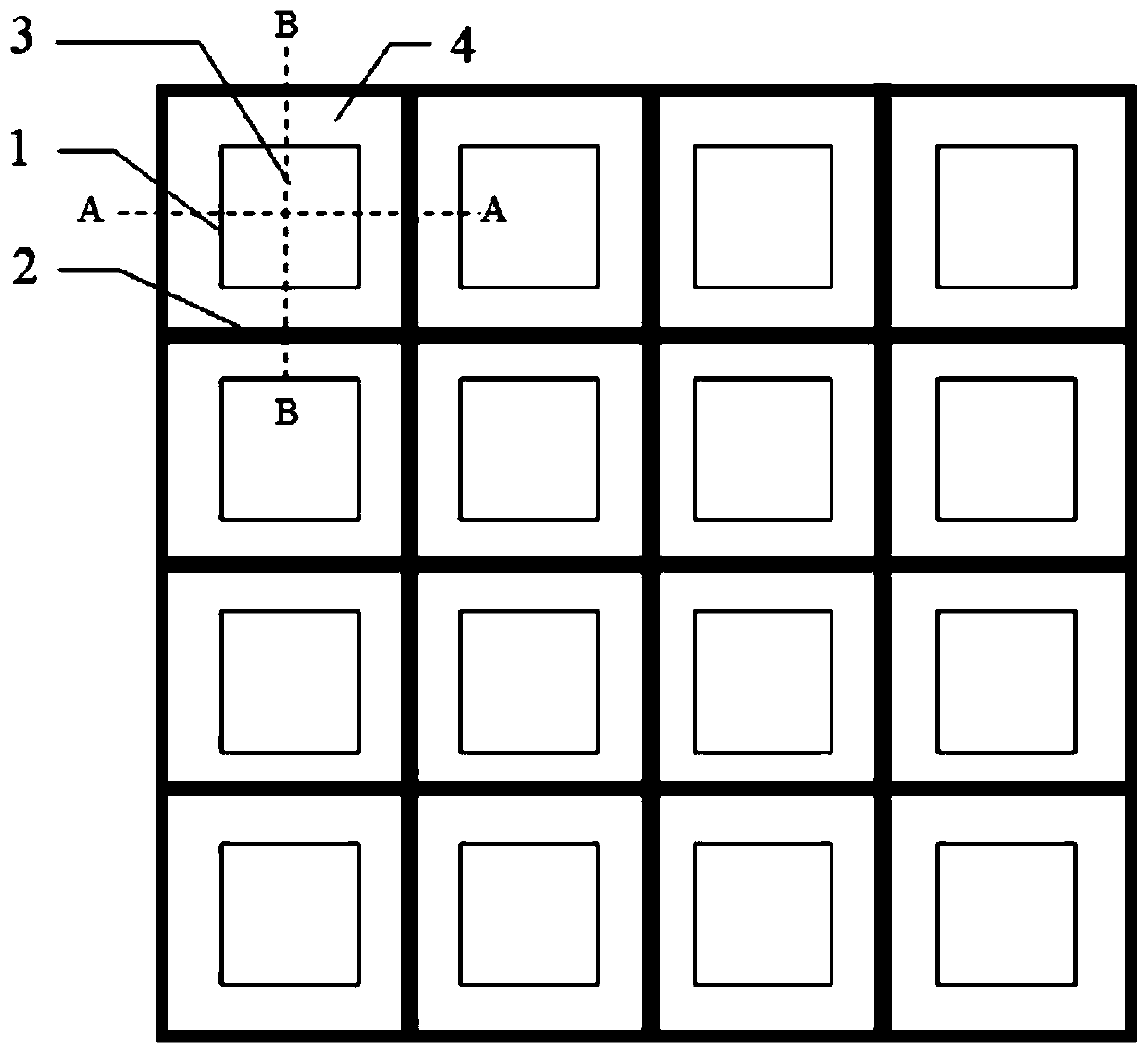

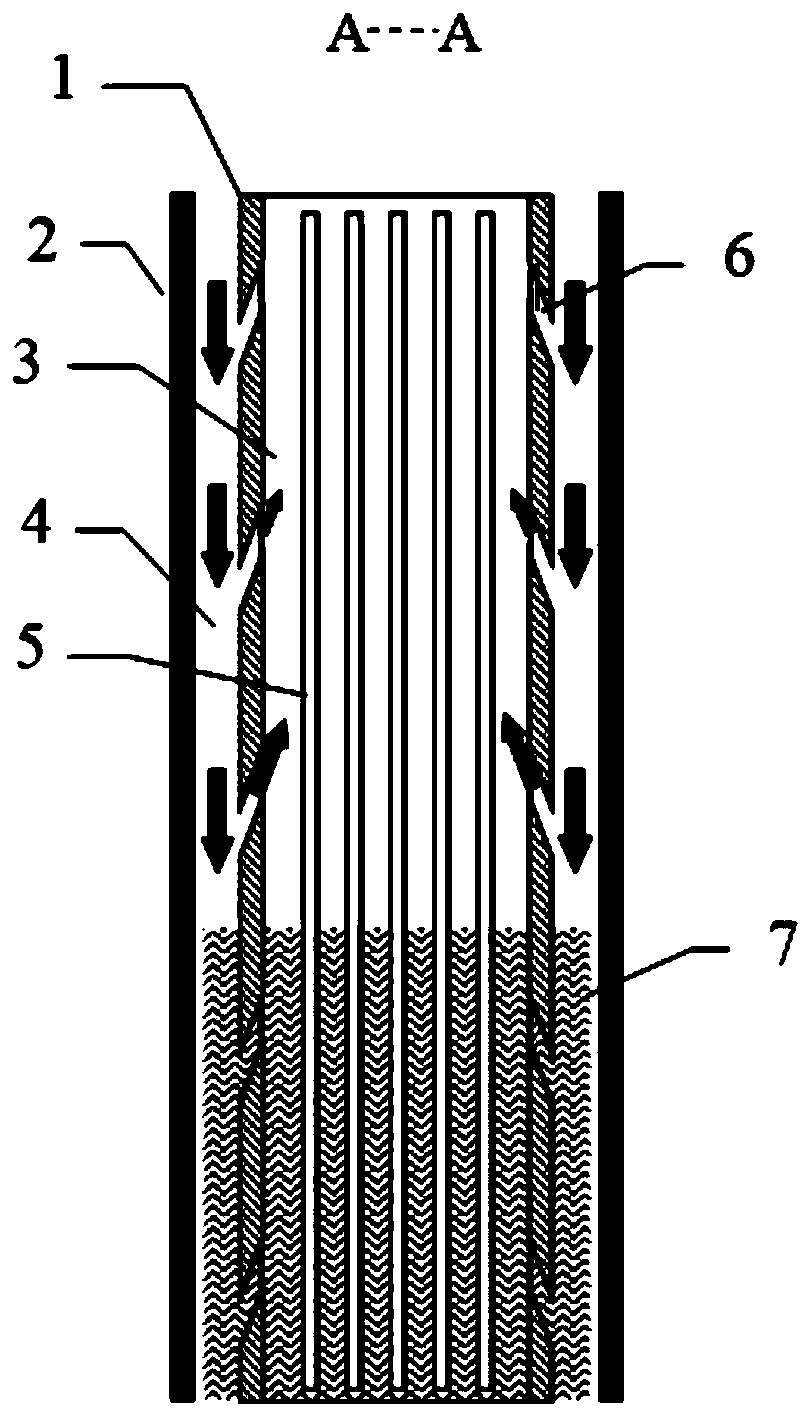

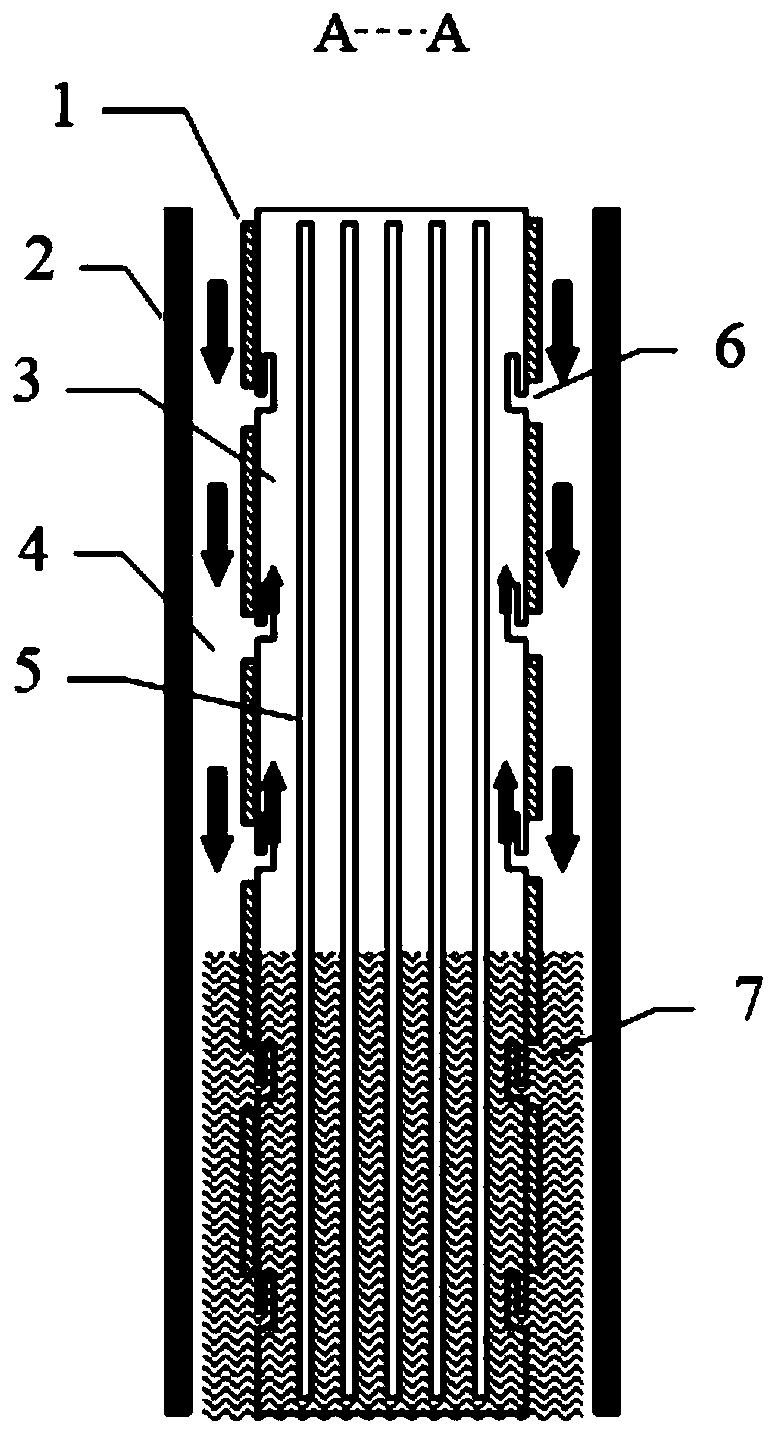

[0021] Such as figure 1 with figure 2 As shown, the present invention provides a high-safety spent fuel storage grid, which includes a plurality of storage grids separated by partitions 2 in an array distribution, and each storage grid is provided with a storage grid for storing spent fuel. In the sleeve 1 of the assembly 5, each sleeve 1 serves as a storage unit 3, the sleeve 1 is perpendicular to the ground, and a number of circulation holes 6 are provided on the side wall of the sleeve 1.

[0022] Between the sleeve 1 and the partition 2 is left a barrier layer 4 capable of passing gas or liquid coolant 7, and the top of the sleeve 1 has an open structure.

[0023] Between the compartment 4 and the sleeve 1 in each storage compartment, the circulation of gas or liquid coolant 7 can be realized through the circulation holes 6 on the side wall of the sleeve 1.

[0024] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com