Stator of outer rotor motor and assembly method

An external rotor motor and stator technology, applied in electromechanical devices, manufacture of stator/rotor body, electrical components, etc., can solve the difficulty in embedding wires of concentrated winding forming coils, easy damage to insulating materials and winding coils, direct winding or embedding of windings Solve problems such as difficult wires, achieve the effects of easy wire embedding, improved air-gap magnetic density waveform, and improved slot fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 provides a stator with pole shoes.

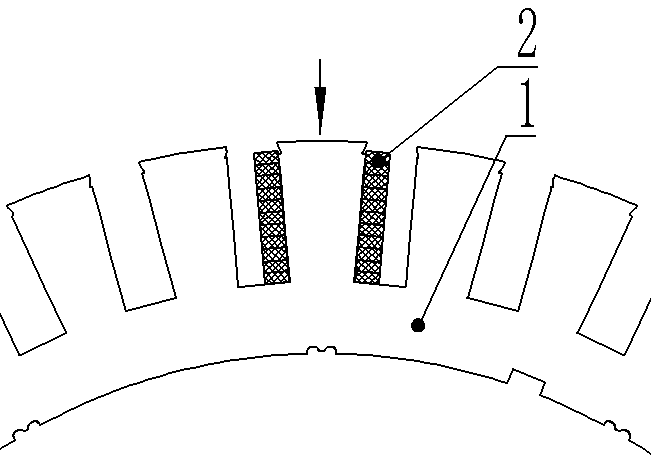

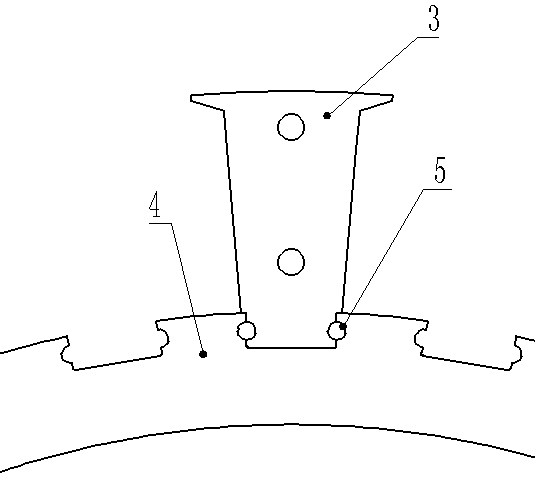

[0039] The stator includes a stator core and a winding coil 2. The stator core is disassembled into a stator yoke 4 and a plurality of stator teeth 3. The plurality of stator teeth 3 are evenly distributed on the outer periphery of the stator yoke 4 in the circumferential direction. All the stator teeth 3 and the stator yoke 4 They are detachably connected together by a splicing structure, and are fixed to each other by pins 5. The stator yoke 4 is an integrated full circle structure. A plurality of stator teeth and the stator yoke 4 form a stator punch, and the stator punches are stacked in multiple layers. Pressed to form the stator core. details as follows:

[0040] A stator of an external rotor motor, a stator core and a winding coil 2, wherein the stator core includes stator teeth 3, a stator yoke 4, and pins 5, and a plurality of stator teeth 3 are evenly distributed on the outer periphery of the stator yoke 4 in ...

Embodiment 2

[0046] Embodiment 2 provides a stator with a cooling medium pipeline.

[0047] The stator includes a stator core and a winding coil 2. The stator core is disassembled into a stator yoke 4 and a plurality of stator teeth 3. The plurality of stator teeth 3 are evenly distributed on the outer periphery of the stator yoke 4 in the circumferential direction. All the stator teeth 3 and the stator yoke 4 They are all detachably connected together by a splicing structure, and are fixed to each other by pin 5, as follows:

[0048] A stator of an external rotor motor, including a stator core and a winding coil 2, wherein the stator core includes stator teeth 3, a stator yoke 4, and pins 5, and a plurality of stator teeth 3 are evenly distributed on the outer periphery of the stator yoke 4 in the circumferential direction, and the stator teeth 3 is detachably connected with the stator yoke 4, the winding coil 2 is wound on the stator yoke 3; a plurality of positioning slots 42 are opened...

Embodiment 3

[0055] Embodiment 3 provides a stator assembly method of an outer rotor motor.

[0056] The method comprises the steps of:

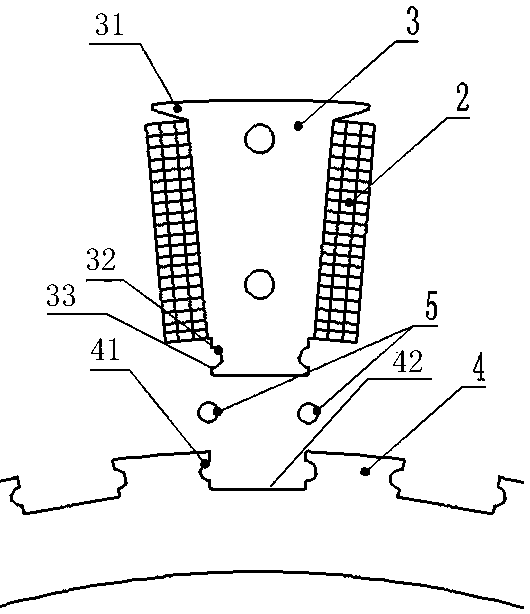

[0057] S1: the first fixing groove 32 is opened on both sides of the fixing head 33 at the bottom of the stator tooth 3;

[0058] S2: The stator yoke 4 is provided with a plurality of positioning slots 42, and the two inner sides opposite to the positioning slots 42 are provided with second fixing slots 41;

[0059] S3: The winding coil 2 is wound on the stator tooth 3 to form a whole;

[0060] S4: Insert the integral fixing head 33 into the positioning groove 42 along the radial direction of the stator yoke 4 so that the first fixing groove 32 and the second fixing groove 41 cooperate to form a cylindrical groove;

[0061] S5: Insert the cylindrical pin 5 into the groove along the axial direction of the stator yoke 4 for fixing;

[0062] Wherein the top of the stator tooth 3 is provided with a pole shoe 31 .

[0063] In a preferred embodiment, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com