Scalable synthesis of hydrogenated alpha styrene dimer

A technology for hydrogenating α-dimethylstyrene and dimer, which is applied in the directions of hydrocarbon copolymer adhesives, hydrogenation to hydrocarbons, carbon compound catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] experiment process

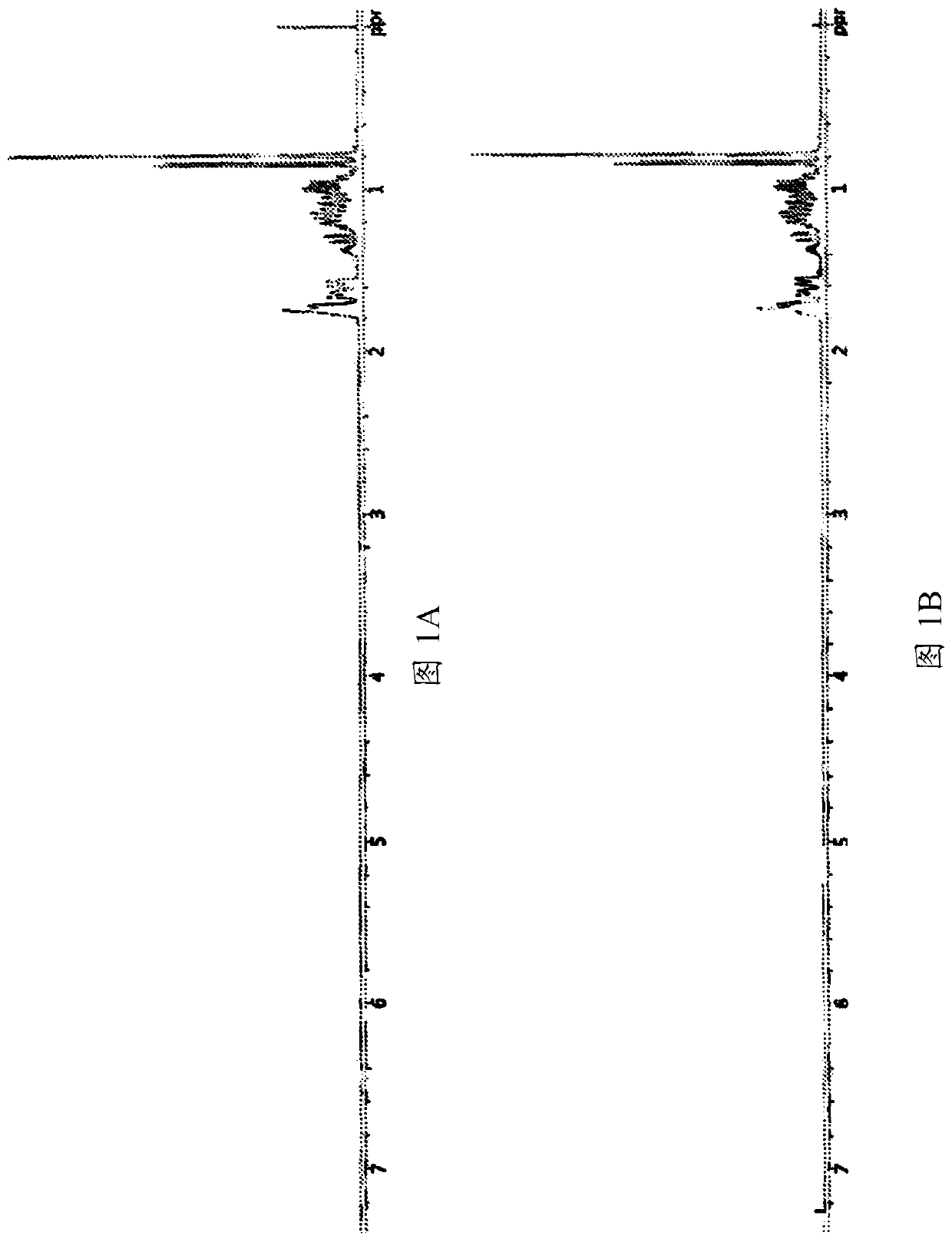

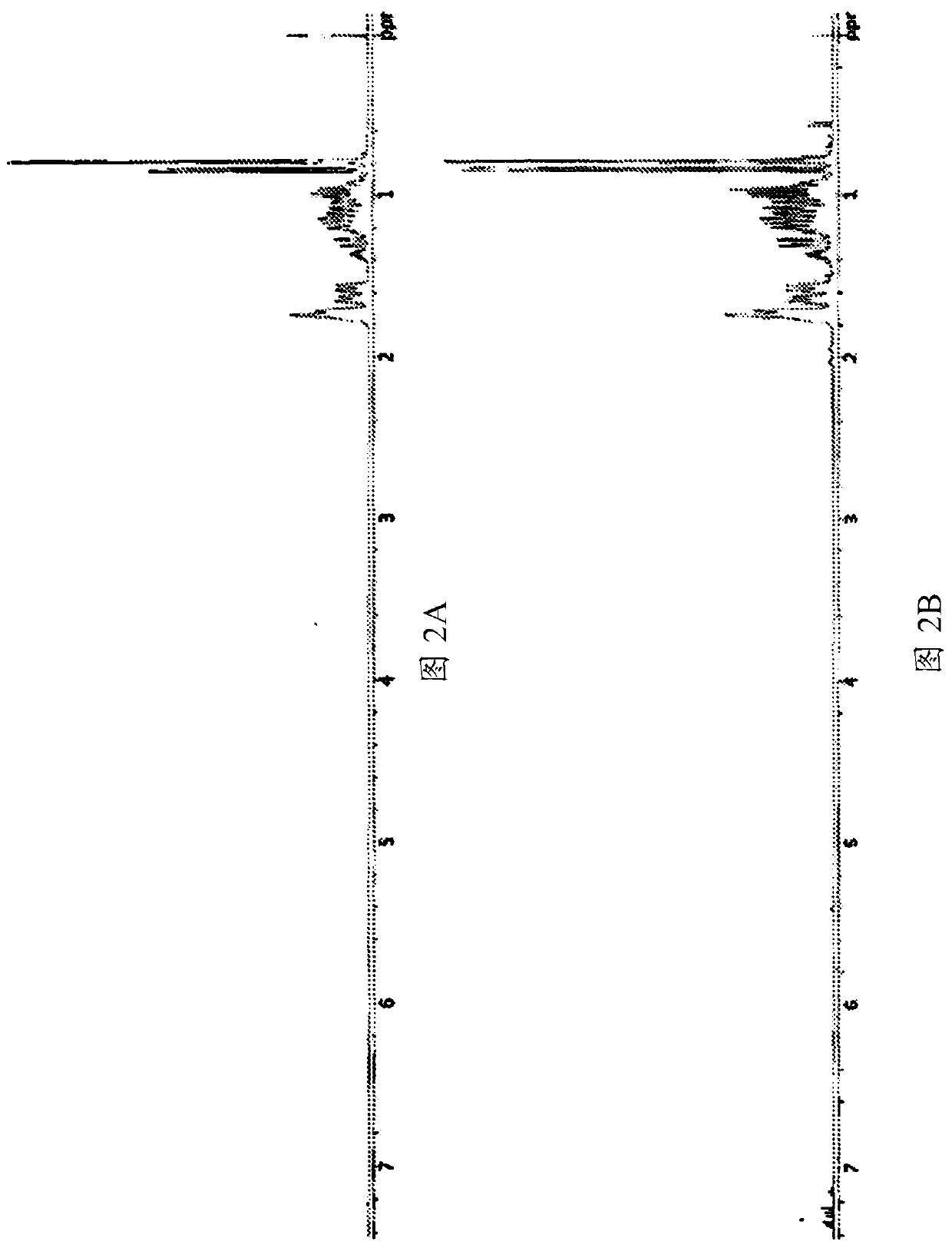

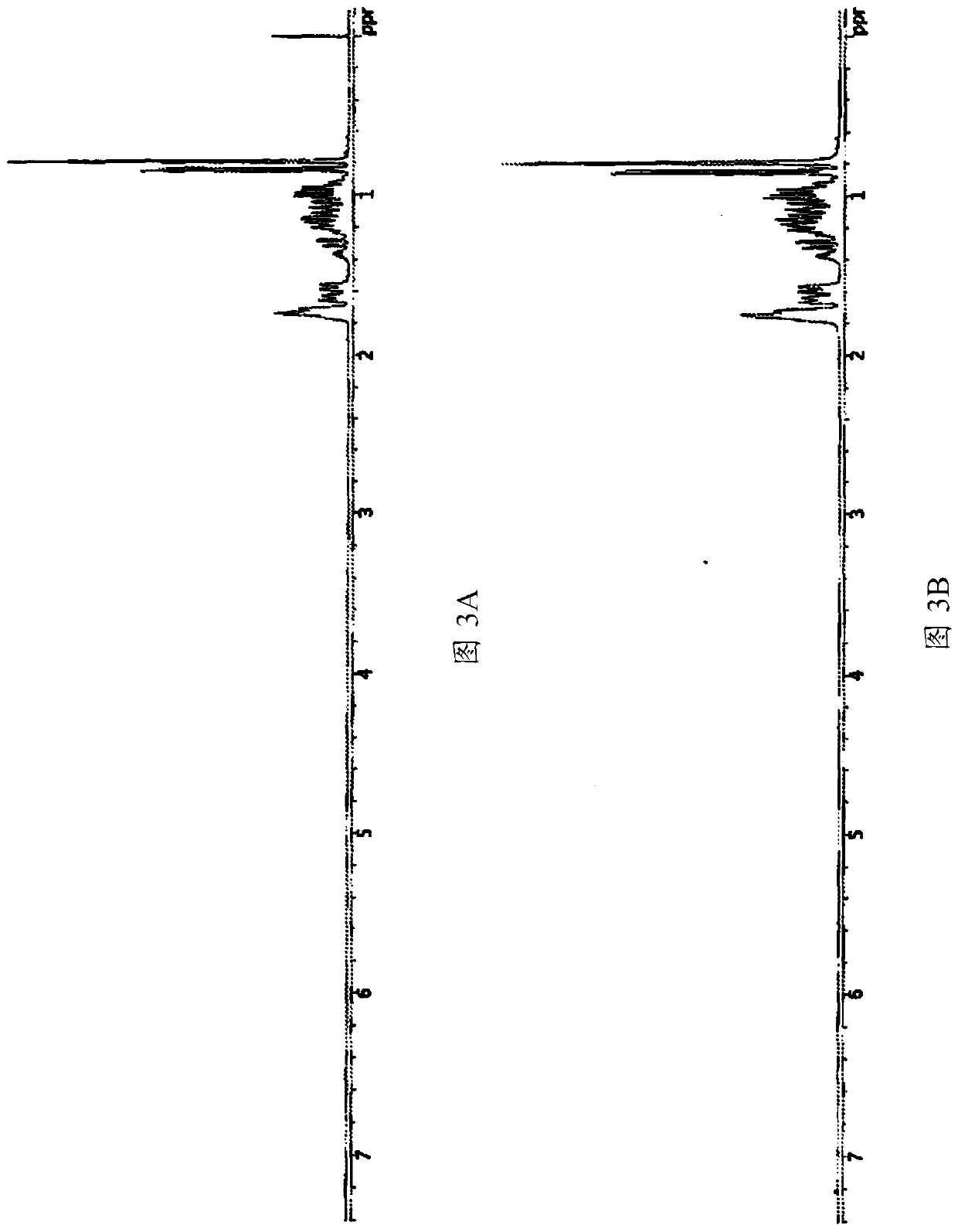

[0037] In a one liter Hastelloy reactor with a turbine impeller, the catalyst is added. In some examples, isopropanol was added to the catalyst under nitrogen. To the resulting catalytic solution was added alpha dimethylstyrene dimer. The reaction mixture was stirred with a stirrer at a constant rate of 1,000 RPM. The reaction mixture was heated to the temperature and pressure shown in Table 1. The completion of the reaction was monitored by thin layer chromatography or NMR, and when hydrogen consumption was no longer indicated, the reaction mixture was filtered through a bed of celite under nitrogen. Products were also analyzed by nuclear magnetic resonance (NMR) or gas chromatography mass spectrometry (GCMS).

[0038] The results are shown in Table 1:

[0039]

[0040]

[0041] In some cases, the catalyst is supplied at 50% by weight in water and the % dry basis can be calculated. According to Table 1, at about 10Kg / cm 2 to about 11Kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com