Construction sand and gravel safe screening device

A screening device, sand and gravel technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of mixed together, different sizes of sand and gravel, affecting the use of buildings, etc., to achieve convenient dust reduction, reduce wear and tear, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

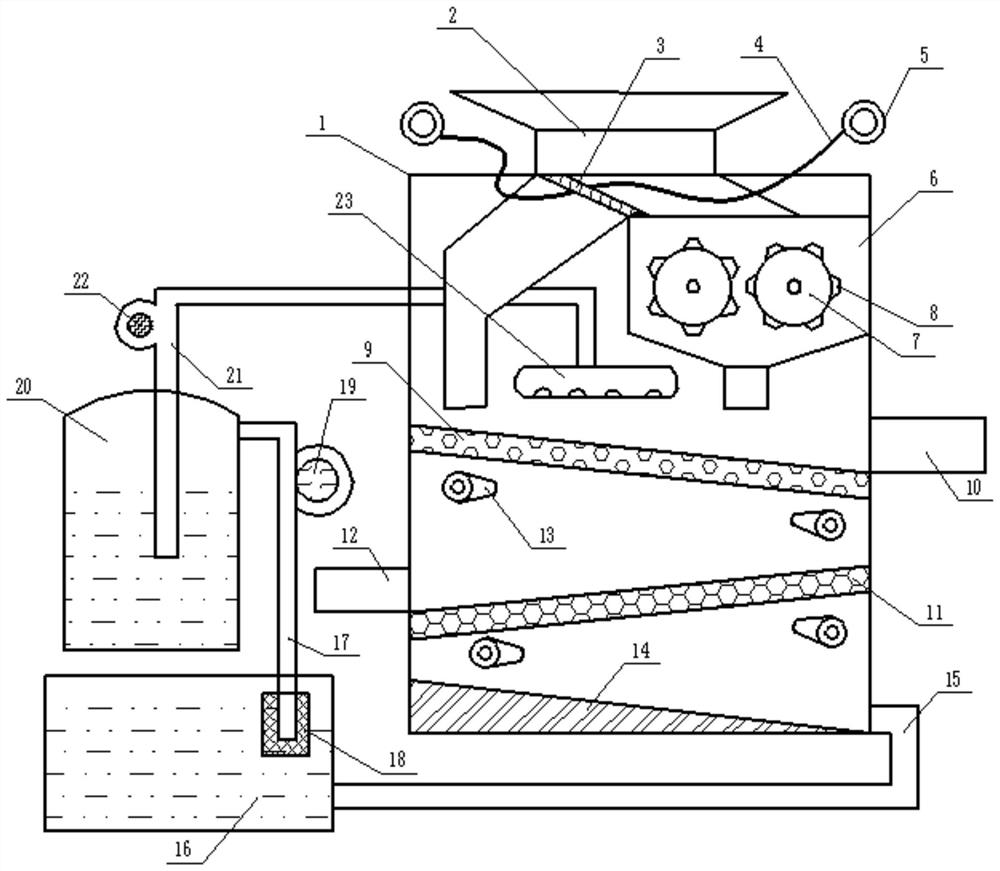

[0021] Example 1: Please refer to Figure 1-3 , a safety screening device for construction sand and gravel, including a treatment box 1, the top of the treatment box 1 is provided with a feed pipe 2, the device is placed on the construction site, and when the sand and gravel are transported to the construction site, it is passed according to actual needs. The feed pipe 2 is put into the treatment box 1 for screening and separation, which facilitates the separation of sand and gravel of different particle sizes, facilitates its subsequent different uses, facilitates the rational utilization of construction sand and gravel, and ensures safety.

[0022] The bottom end of the feed pipe 2 is connected to the first communication pipe and the second communication pipe at the same time, the first communication pipe and the second communication pipe form a "herringbone" shape, the top joints of the first communication pipe and the second communication pipe and the partition 3. The bott...

Embodiment 2

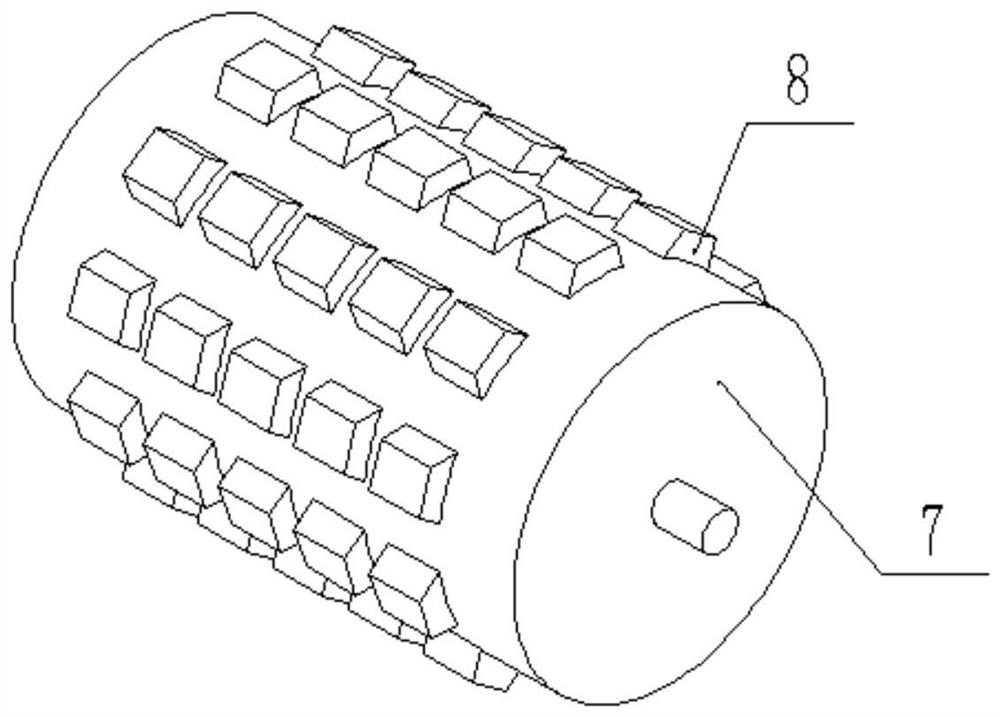

[0027] Embodiment 2: On the basis of Embodiment 1, there are multiple groups of crushing rollers 7 inside the crushing box 6, and the outer wall of the crushing rollers 7 is evenly equipped with crushing teeth 8. The multiple groups of crushing rollers 7 are set through the mutual engagement of the crushing teeth 8. The rotation of the external motor drives the crushing roller 7 and the crushing teeth 8 to facilitate the crushing of large pieces of sand and gravel, which facilitates subsequent screening of the required sand and gravel, which is beneficial to the use of buildings and ensures safety.

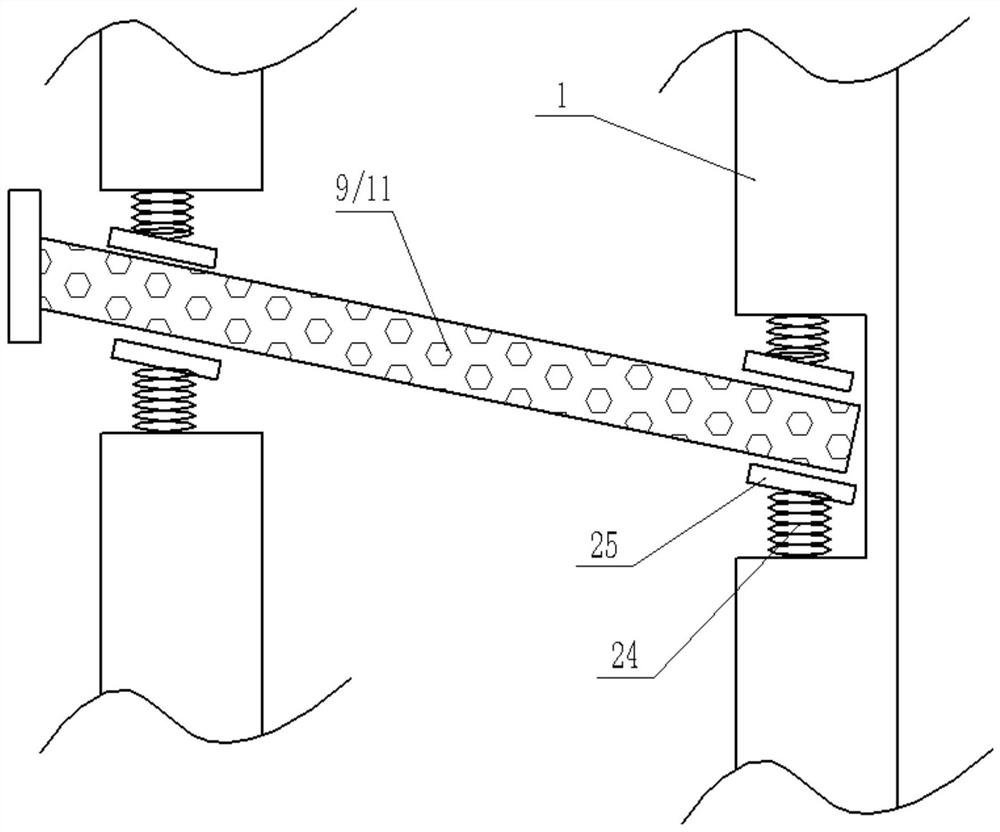

[0028]The treatment box 1 is plugged in to the first sieve plate 9 and the second sieve plate 11. According to the actual situation and needs, a suitable sieve plate with different sieve hole sizes is selected to facilitate the separation of sand and gravel into different particle sizes, which is beneficial to its subsequent operation. Different construction materials, easy to use....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com