Round pipe inner wall rustproof polishing device based on machining

A technology for machining and round pipes is applied in the field of anti-rust grinding devices for the inner wall of round pipes, which can solve problems such as wasted man-hours, and achieve the effects of increasing contact frequency and improving grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

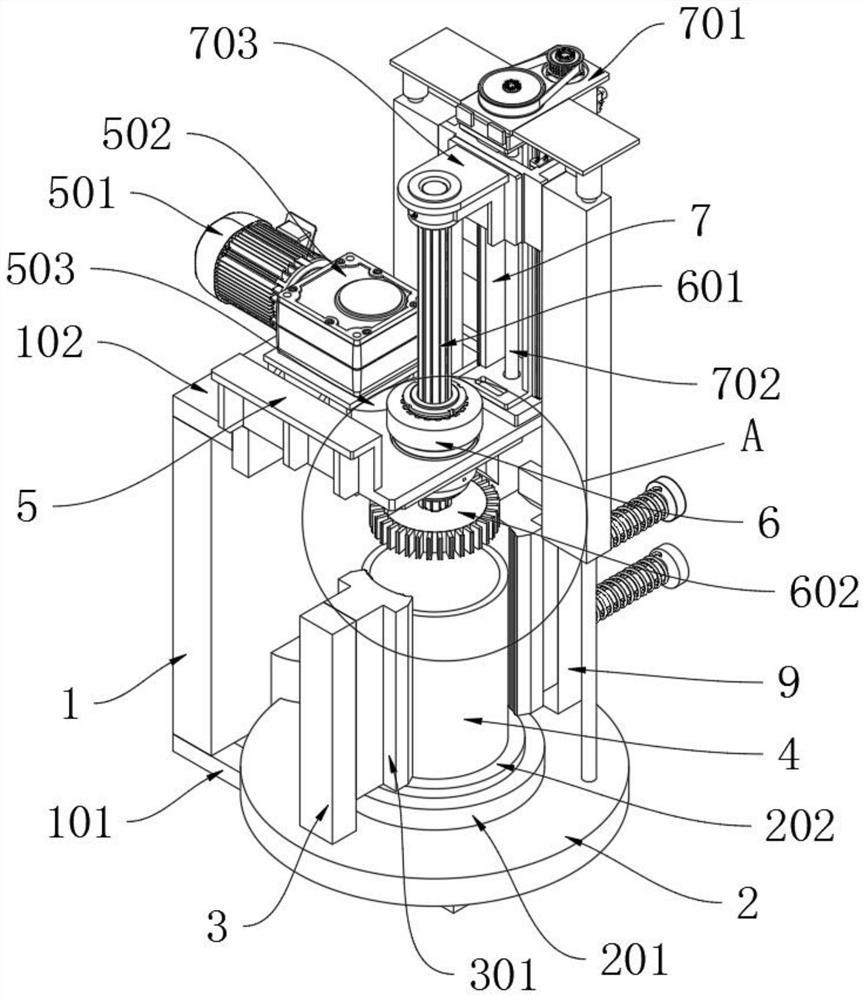

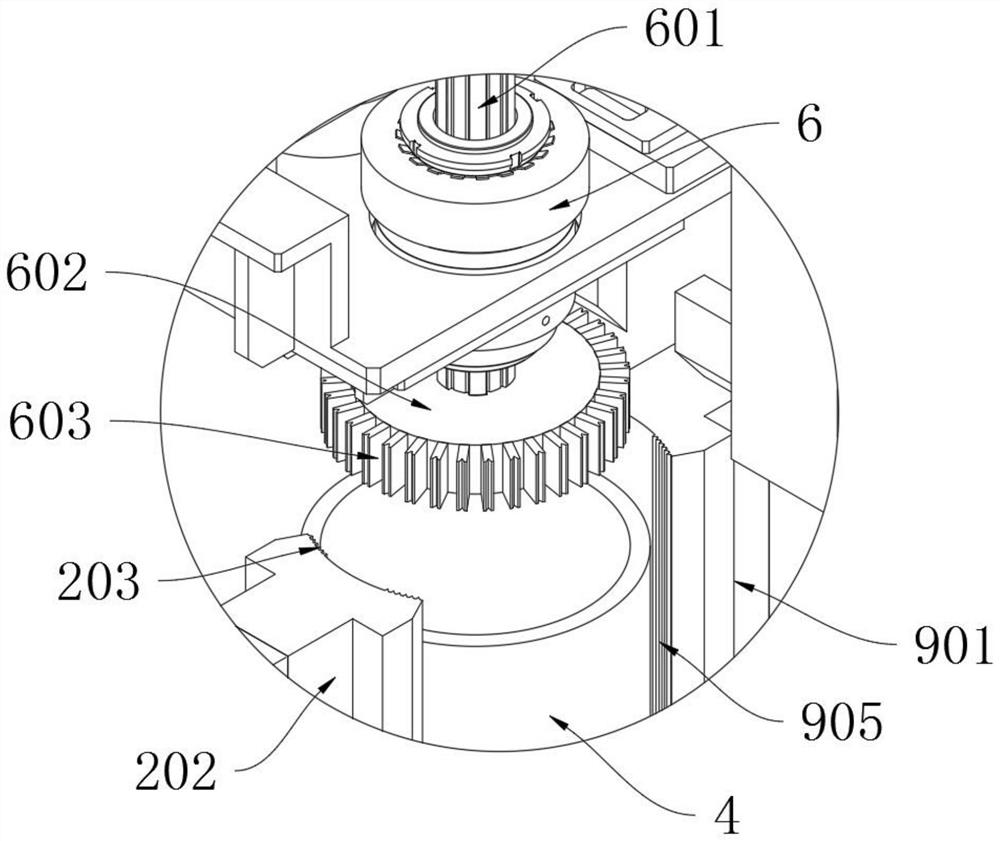

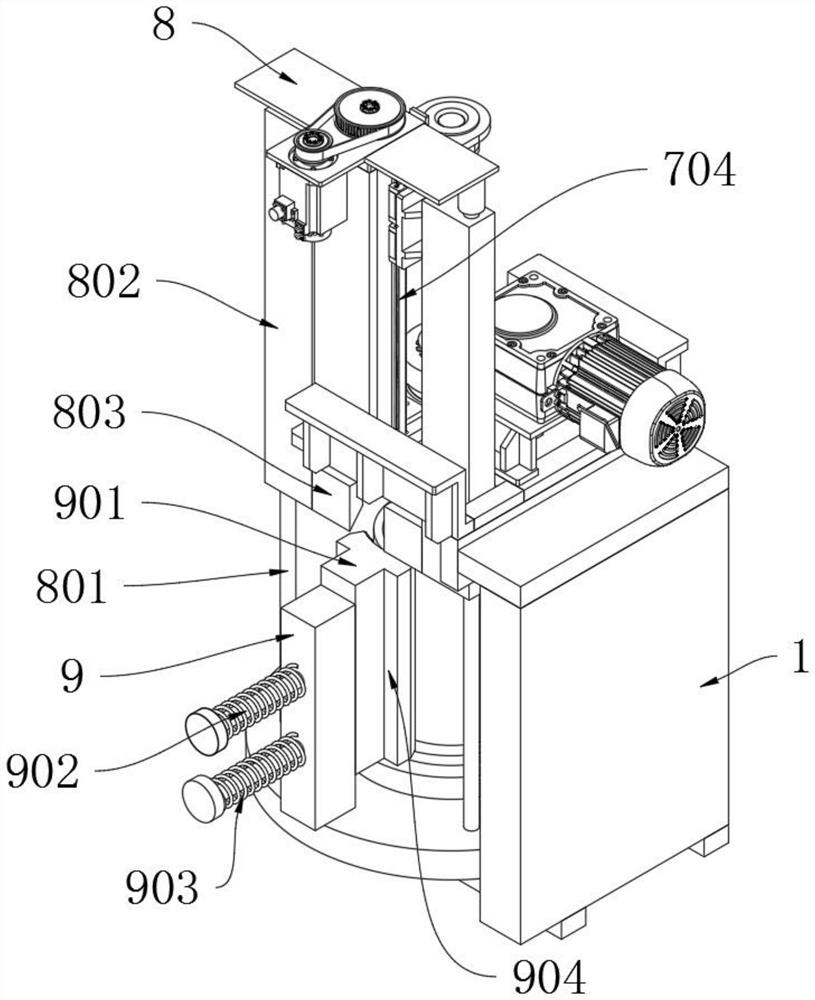

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The invention provides a machine-based anti-rust grinding device for the inner wall of a circular tube, which includes a bottom frame 1; 2, while the upper end of the chassis 1 is fixedly installed with a rotating mechanism 5 horizontally to the right; the middle part of the right end of the rotating mechanism 5 is vertically equipped with a grinding mechanism 6, and its grinding mechanism 6 corresponds to the position of the grinding table 2; the grinding table 2 includes The seat plate 201, the card edge 202 and the blanking hole 203, the middle part of the top plane of the grinding table 2 is fixedly equipped with a disc-shaped seat plate 201, and the inner side of the upper edge of the top plane of the seat plate 201 is fixedly installed with a ring-shaped card edge 202, the grinding table 2 on the inner side of the card edge 202 is provided with a conical blanking hole 203 with a wide upper part and a narro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com