PCB taking mechanism

A technology of reclaiming mechanism and PCB board, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of wasting time and affecting production efficiency, and achieve the effect of improving operation accuracy, improving production efficiency, and reducing disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

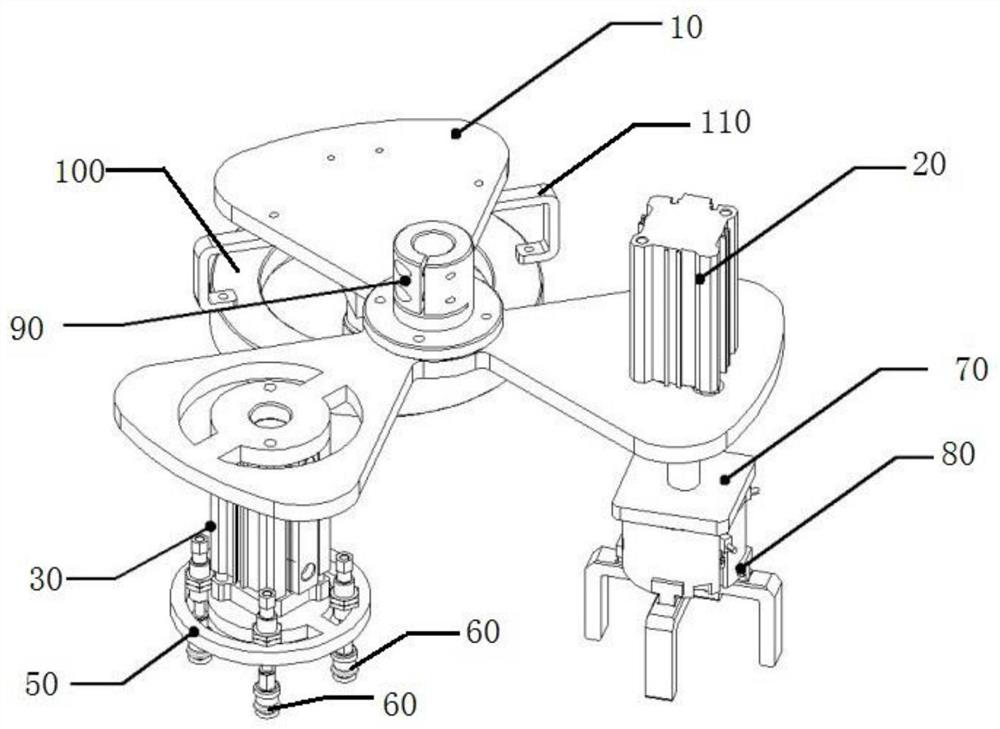

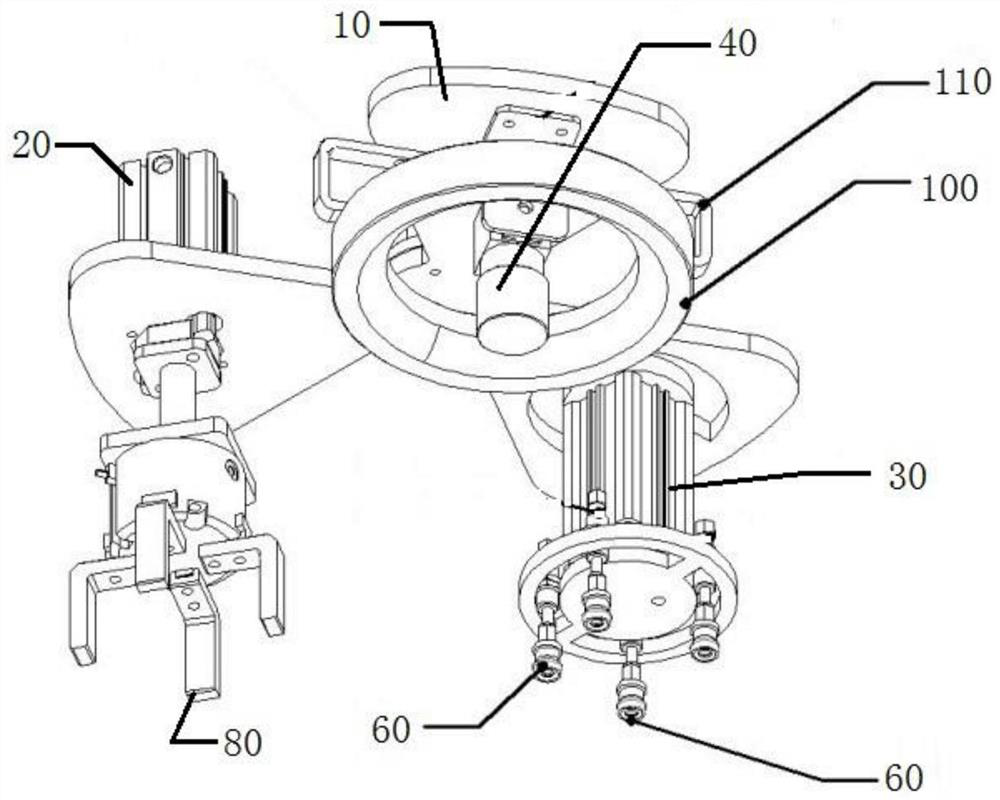

[0012] Combine below Figure 1-2 , to further describe the present invention.

[0013] A PCB board material retrieving mechanism, comprising a mounting substrate 10, a fixed jaw propelling cylinder 20, a suction cup propelling cylinder 30 and a smart camera 40 are installed on the mounting substrate 10, and the end of the piston rod of the clamp propelling cylinder 20 is installed with a suction cup through a suction cup mounting plate 50 60, the end of the piston rod of the suction cup propulsion cylinder 30 is installed with the pneumatic gripper 80 through the gripper mounting plate 70, the mechanism adapter sleeve 90 for connecting with the output shaft of the motor is fixed on the installation substrate 10, the smart camera 40, the suction cup 60 and the pneumatic The jaws 80 are arranged on the same side of the installation substrate 10 , the mechanism adapter sleeve 90 is arranged on the other side of the installation substrate 10 , and the visual light source 100 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com