Bag type packaging machine

A packaging machine, bag-type technology, applied in packaging, packaging protection, multiple packaging parts, etc., can solve the problems of sealing quality interference, broken bags, air leakage, reducing the quality of packaging bags, etc., to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

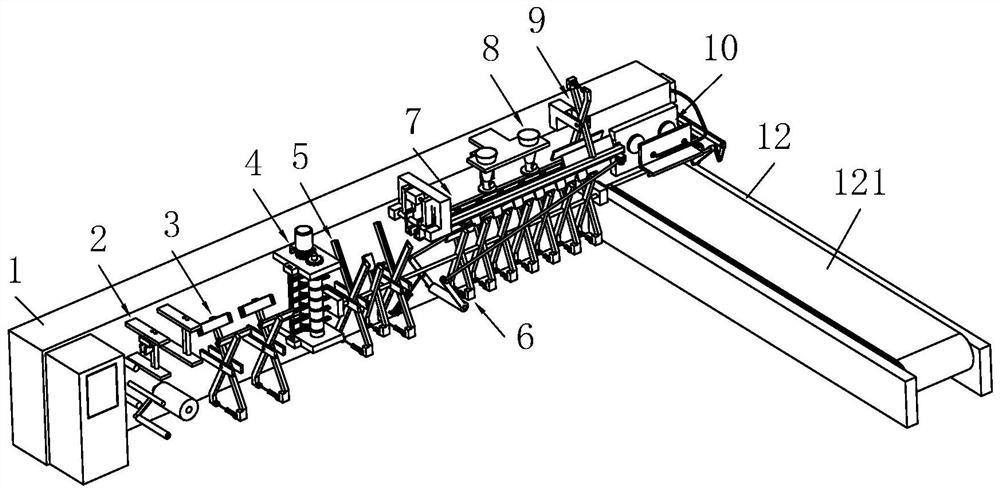

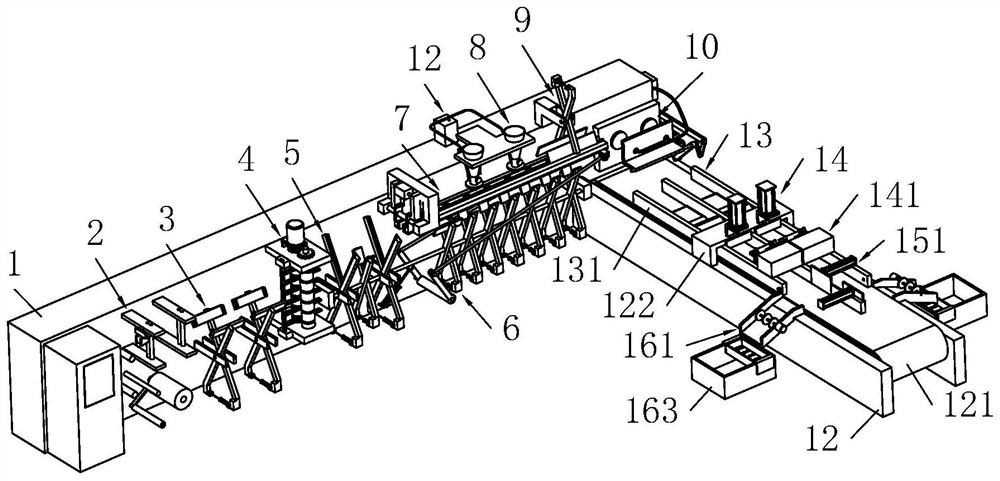

[0049] refer to figure 2 , is a kind of bag packaging machine invented, including a frame 1, on which a folding mechanism 2, a side heat sealing mechanism 3, a driving mechanism 4, a cutting mechanism 5, and a bag opening mechanism are arranged at intervals along the running direction of the packaging bag 6. Bag feeding mechanism 7, feeding mechanism 8, end heat sealing mechanism 9, and feeding mechanism 10; and side heat sealing mechanism 3, cutting mechanism 5, bag opening mechanism 6, and end surface heat sealing mechanism 9 are along the conveying direction of the packaging bag The projections are scissor-shaped.

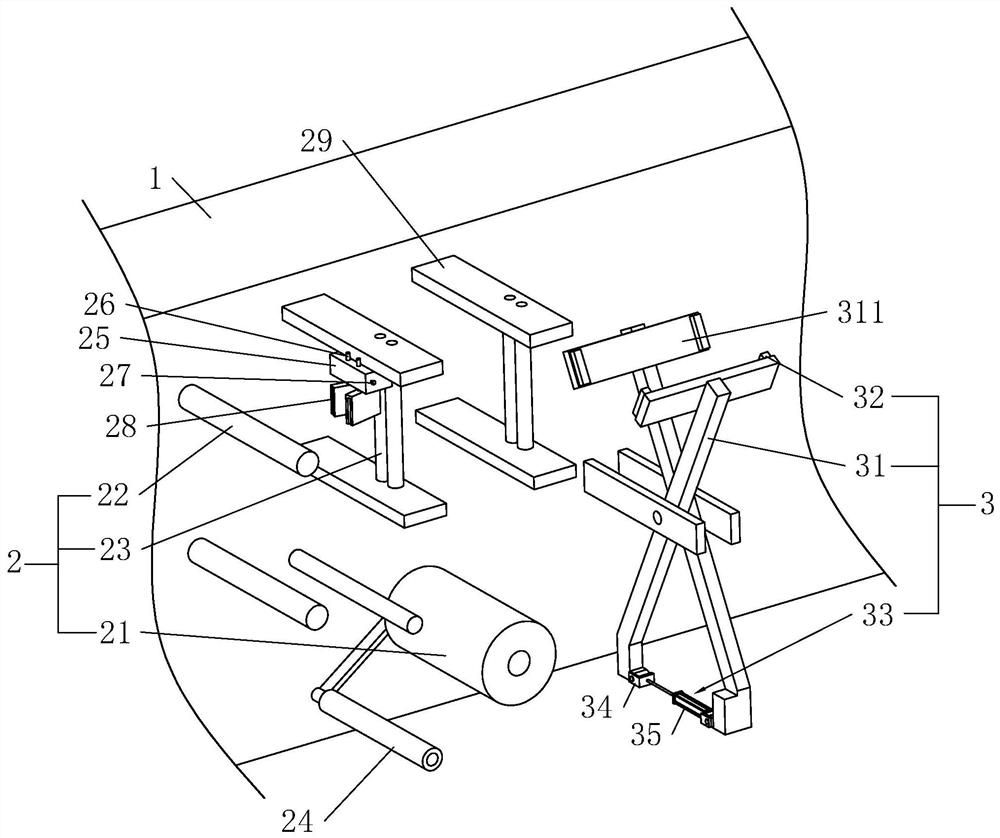

[0050] refer to figure 2 and image 3 , the folding mechanism 2 includes a coiling roll 21, a guide roll 22, and a folding roll 23, the coiling roll 21 is rotatably mounted on the frame 1, and the coiling roll 21 is wound with a film-like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com