DS-3 type glass tire blowing machine

A DS-3, tire blowing machine technology, applied in the special transmission machinery of glass blowing machine, glass blowing, glass forming and other directions, can solve the problem of inability to meet the processing of large glass products, high product rejection rate, poor sealing, etc. problems, to achieve the effect of improving production environmental conditions, simple equipment operation, and reducing labor dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

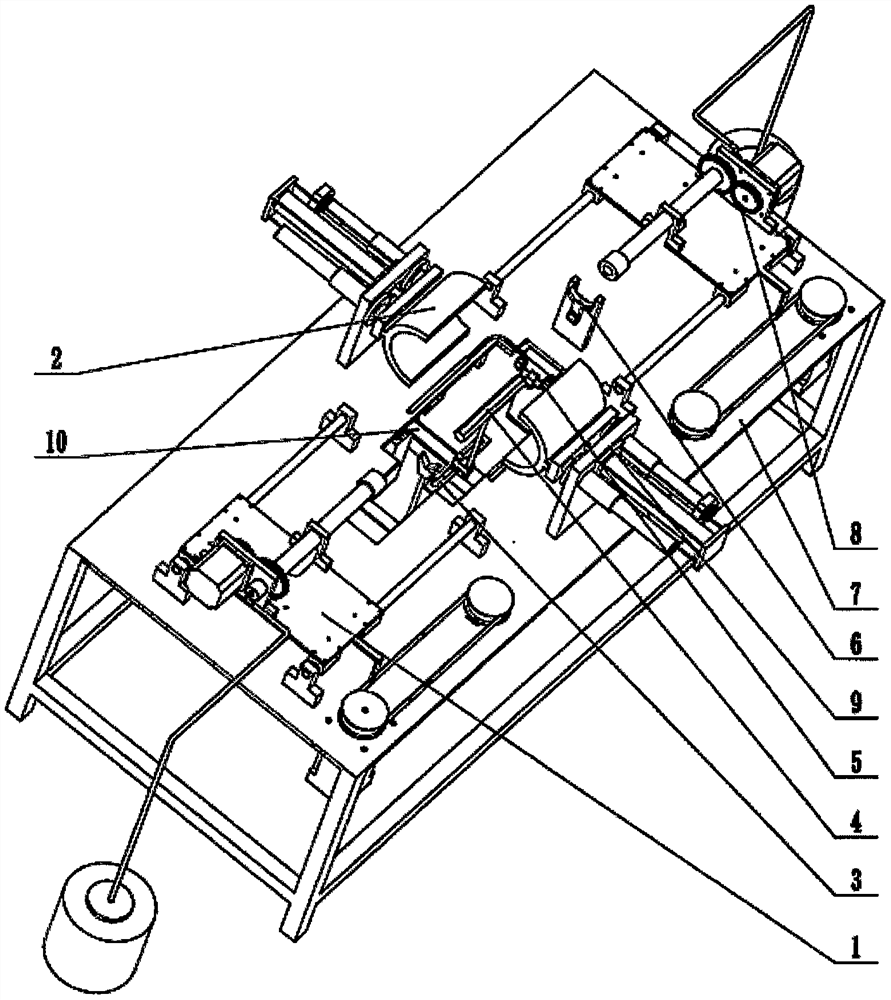

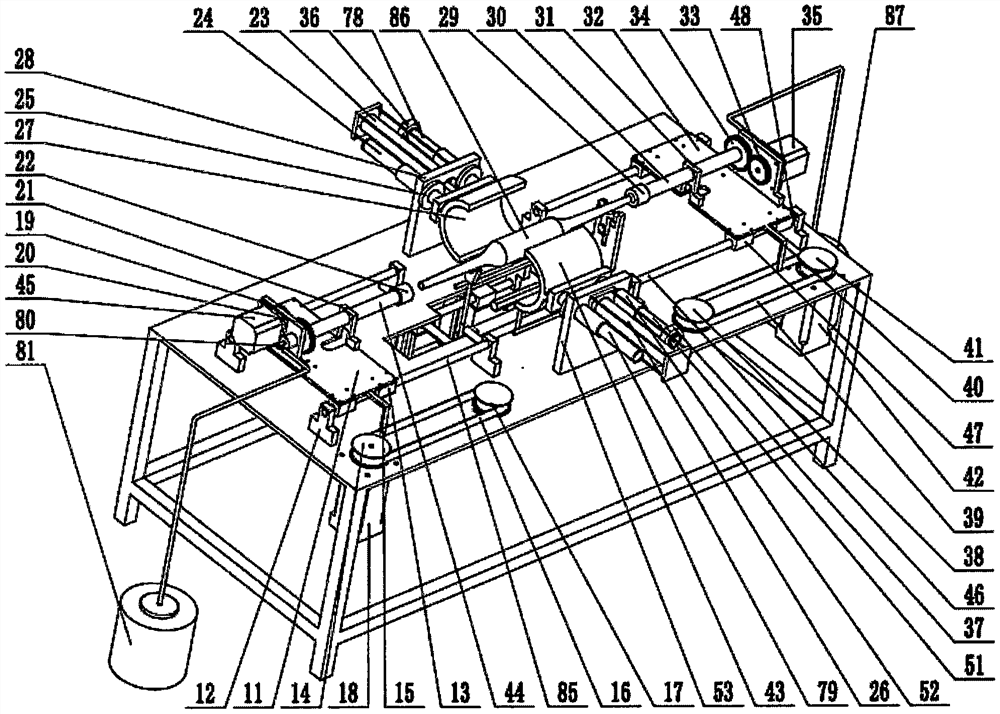

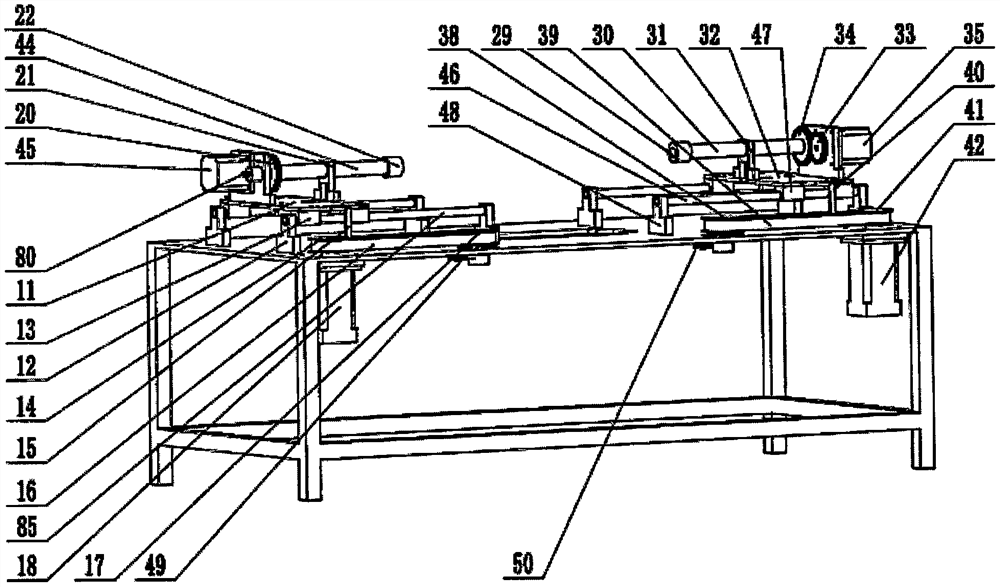

[0041] Further introduce the present invention below in conjunction with embodiment and accompanying drawing, see Figure 1-11 . The embodiments are specific implementations carried out on the premise of the technical solutions of the present invention, and detailed implementation methods and processes are given, but the protection scope of the application is not limited to the following descriptions of the embodiments.

[0042] The DS-3 type glass blowing machine of the present invention (referred to as the blowing machine), the blowing machine includes a workbench 7, A1 glass blank transport clamping rotary module 1, A2 glass blank transport clamping rotary module 8, B1 mold opening and closing module 2, B2 Mold opening and closing module 9, mold water bath cooling module 5, fire head lifting module 4, support lifting module 3, workbench 7, lifting movement auxiliary module 10.

[0043] A1 glass blank conveying and clamping rotary module 1 and A2 glass blank conveying and c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap