Device for realizing automatic evaporation of ceramic target materials through electron beam physical vapor deposition

A physical vapor deposition, ceramic target technology, applied in vacuum evaporation plating, ion implantation plating, metal material coating process and other directions, can solve problems such as unfavorable popularization and application, large manual workload, complex hardware structure, etc. Improve process stability, good thickness repeatability, uniform and stable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only for illustration and are not intended to limit the present invention.

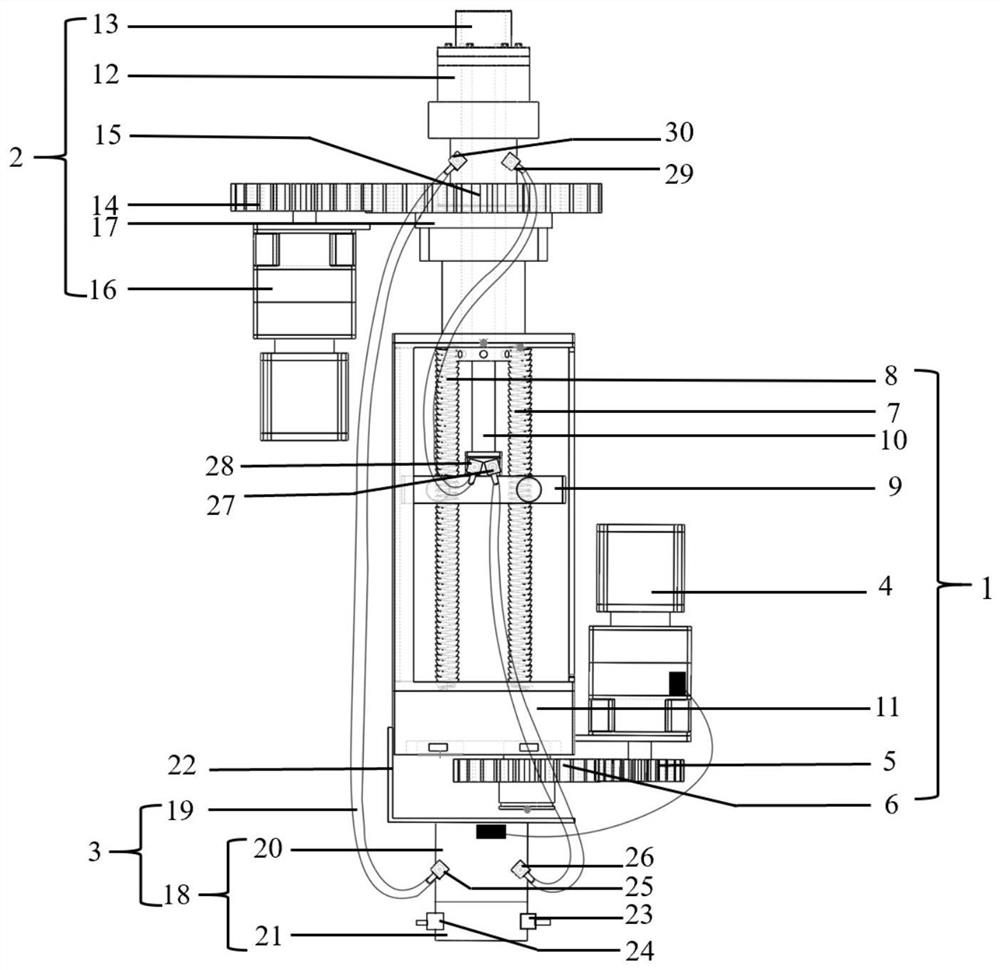

[0037] The present invention provides a device for automatically evaporating ceramic targets by electron beam physical vapor deposition, such as figure 1 As shown, including: lifting assembly 1, rotating assembly 2 and water cooling assembly 3; wherein,

[0038] The lifting assembly 1 is used to control the rising speed of the target, including the lifting motor 4, the lifting driving gear 5, the lifting driven gear 6, the first screw 7, the second screw 8, the lifting slider 9, the lifting rod 10 and the lifting frame 11; Wherein, the lifting motor 4 is connected with the lifting driving gear 5 for controlling the rotation of the lifting driving gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com