Method and Application of Vibration-Assisted Static CPT

A static penetration and vibration technology, used in construction, infrastructure engineering, field foundation soil survey, etc., can solve problems such as no application value, and achieve the effect of simple and clear operation process, improved application scope, and accurate survey.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

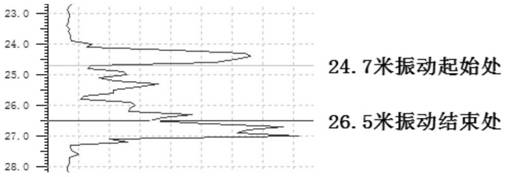

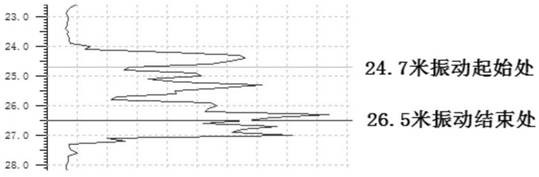

[0069] Example 1: Site survey of Qingguang Demonstration Town, Beichen District, Tianjin, the geological conditions are as follows:

[0070] The buried depth of the site is more than 60 meters, and the layered soil in the horizontal direction is relatively uniform, and the vertical layer is distributed in layers. The stratum is as follows:

[0071] Burial depth 0-1.0m: artificial fill layer (Qml) plain fill (stratum number ① 2 ), brown, soft plastic state, silty clay, belonging to medium compressive soil;

[0072] Burial depth of 1.0-2.5 meters: recent alluvium (Q 4 3N al) Silt soil (stratum number ③ 1 ), brownish-yellow, slightly dense, without bedding, ferrous, partly silty clay, belonging to medium (low) compressibility soil;

[0073] Burial depth of 2.5-6.0 meters: recent alluvium (Q 4 3N al) Clay (stratum number ③ 2 ), brownish-gray, plastic to soft plastic state, without bedding, iron-containing, belonging to highly compressible soil;

[0074] Burial depth of 6.0...

Embodiment 2

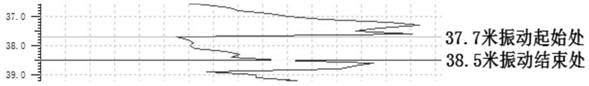

[0095] Example 2: The investigation project of Xinhua Road Stadium in Heping District, Tianjin, the geological conditions are as follows:

[0096] The buried depth of the site is more than 50 meters, and the stratified soil in the horizontal direction is relatively uniform, and the vertical distribution is layered. The stratum is as follows:

[0097] Burial depth 0-1.5 meters: artificial filling layer (Qml) miscellaneous filling (stratum number ① 1 ), in a mottled, loose state, composed of bricks, concrete slag, waste soil, etc.;

[0098] Buried at a depth of 1.5-5.0 meters: the continental alluvium of the Upper Holocene Formation (Q 4 3 al) Silty clay (stratum number ④ 1 ), grayish yellow, plastic state, no bedding, ferrous, belonging to medium compressibility soil;

[0099] Buried at a depth of 5.0-6.5 meters: the continental alluvium of the Upper Holocene Formation (Q 4 3 al) Silt soil (stratum number ④ 2 ), greyish-yellow, slightly dense state, no bedding, ferrous, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com