Three-dimensional integrated programmable optical filter

An optical filter and three-dimensional integration technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as bending loss, achieve the effects of improving transmission efficiency, saving chip area, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

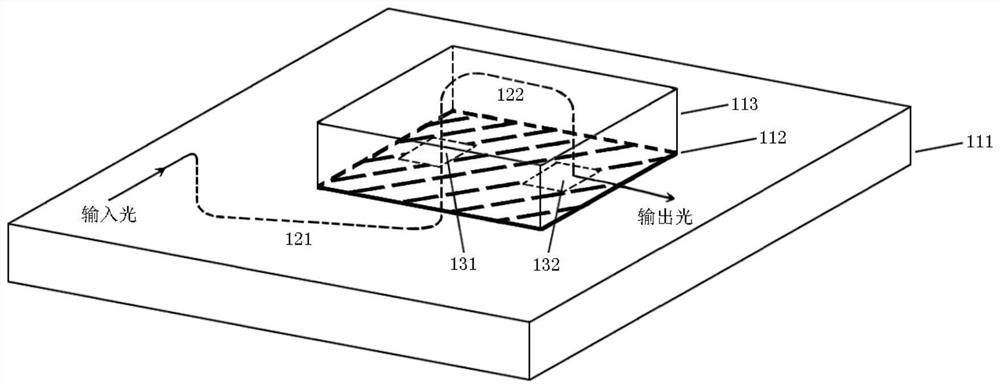

[0024] The present invention designs a three-dimensional integrated programmable optical filter, such as figure 1 As shown, it includes a substrate layer 111 , an opaque layer 112 and a flip-chip bonding layer 113 . The flip-chip bonding layer 113 and the substrate layer 111 are independent chips, the first-stage filter 121 is fabricated on the substrate layer 111 , and the second-stage filter 122 is fabricated on the flip-chip bonding layer 113 . The first-stage filter 121 and the second-stage filter 122 are both single-stage tunable optical filters, and a first coupling region 131 and a second coupling region 132 are arranged on the light-proof layer 112, and the first-stage filter The filter 121 and the second-stage filter 122 are connected through a first coupling region 131 and a second coupling region 132 .

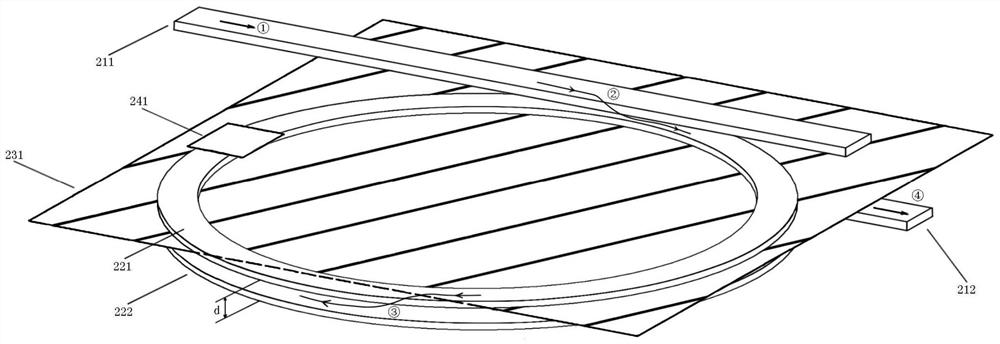

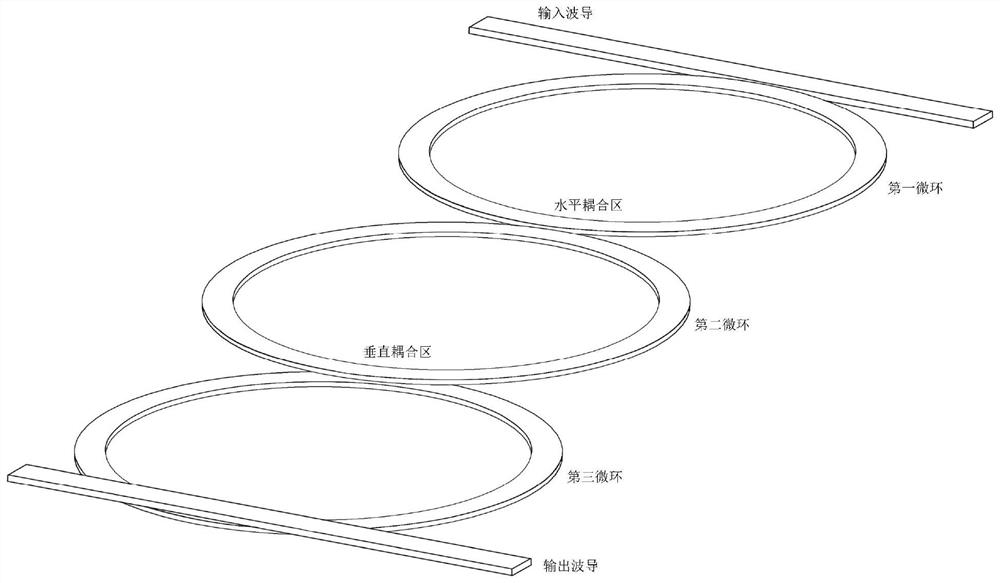

[0025] The basic struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com