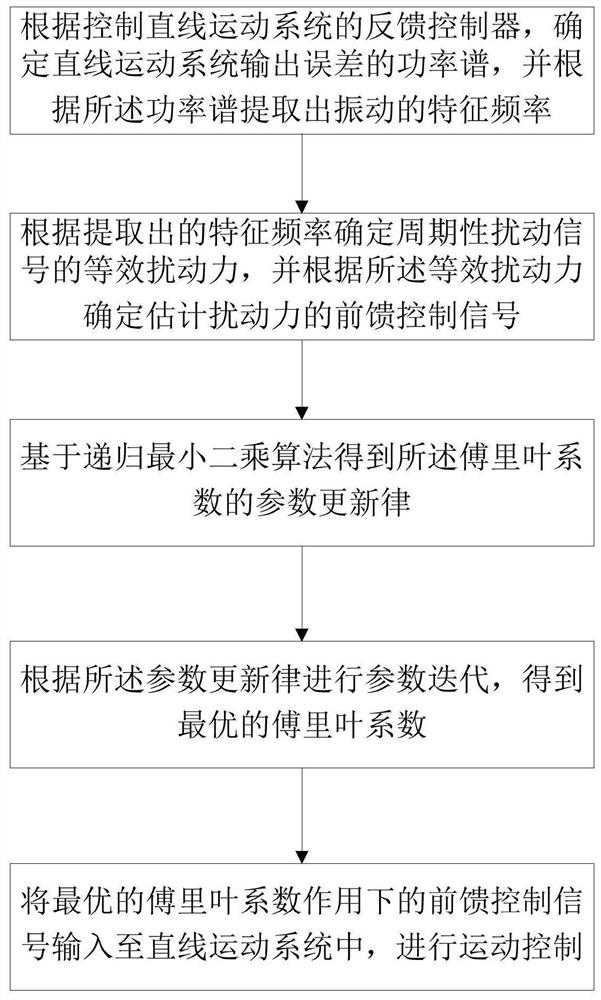

Adaptive Recursive Feedforward Control Method for Linear Motion System

An adaptive recursive and feedforward control technology, applied in adaptive control, general control systems, control/regulation systems, etc., can solve problems such as slow dynamic response, achieve fast dynamic response, improve dynamic response performance, and reduce computational complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described below with reference to the accompanying drawings. Those skilled in the art would recognize that the described embodiments can be modified in various ways or combinations thereof without departing from the spirit and scope of the invention. Accordingly, the drawings and description are illustrative in nature and not intended to limit the scope of the claims. Also, in this specification, the drawings are not drawn to scale, and like reference numerals denote like parts.

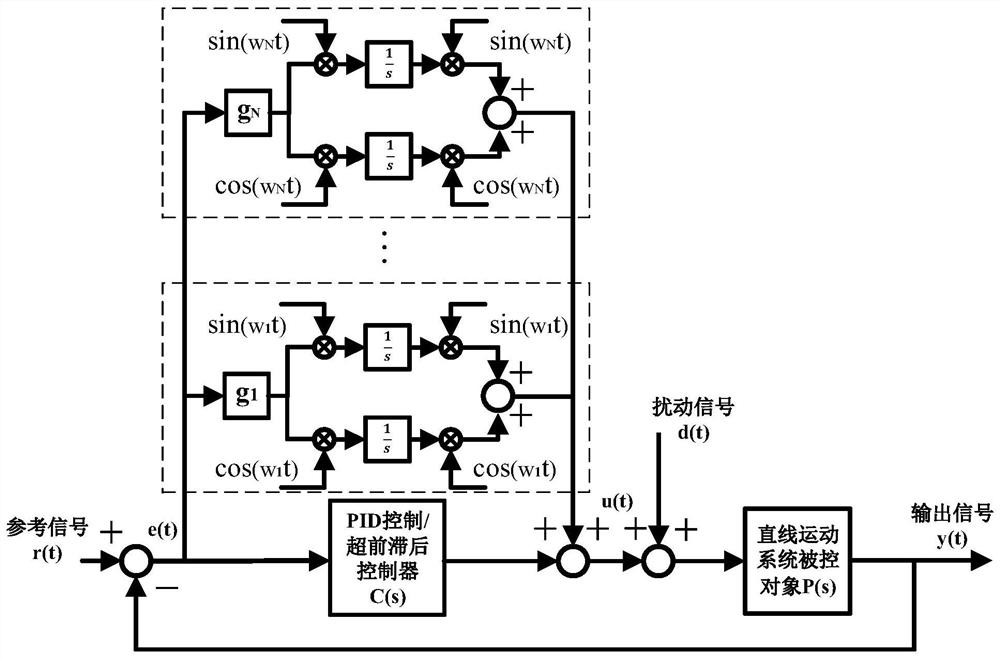

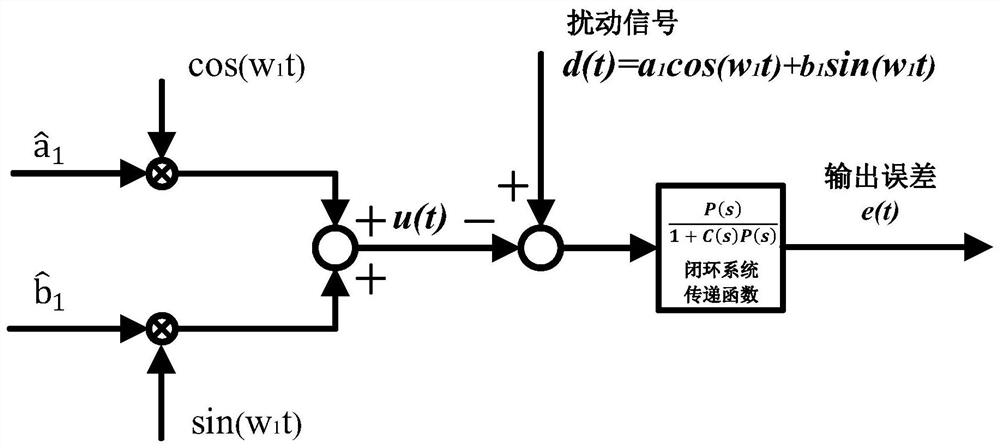

[0048] In the relevant control field of ultra-precision linear motors in step-scanning lithography machines, there are extremely high precision requirements for trajectory tracking accuracy, settling time, and dynamic response speed. These control performances directly determine the overlay of the lithography machine. Accuracy, resolution, productivity and other indicators. The self-adaptive recursive feed-forward control method of the invention c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com