Dynamic vibration absorber applied to tank wall of oil-immersed transformer

An oil-immersed transformer, dynamic vibration absorption technology, applied in transformer/inductor cooling, transformer/inductor noise damping, non-rotational vibration suppression, etc. Problems, to achieve the effect of convenient replacement and maintenance, improve firmness, and improve the effect of dynamic vibration absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

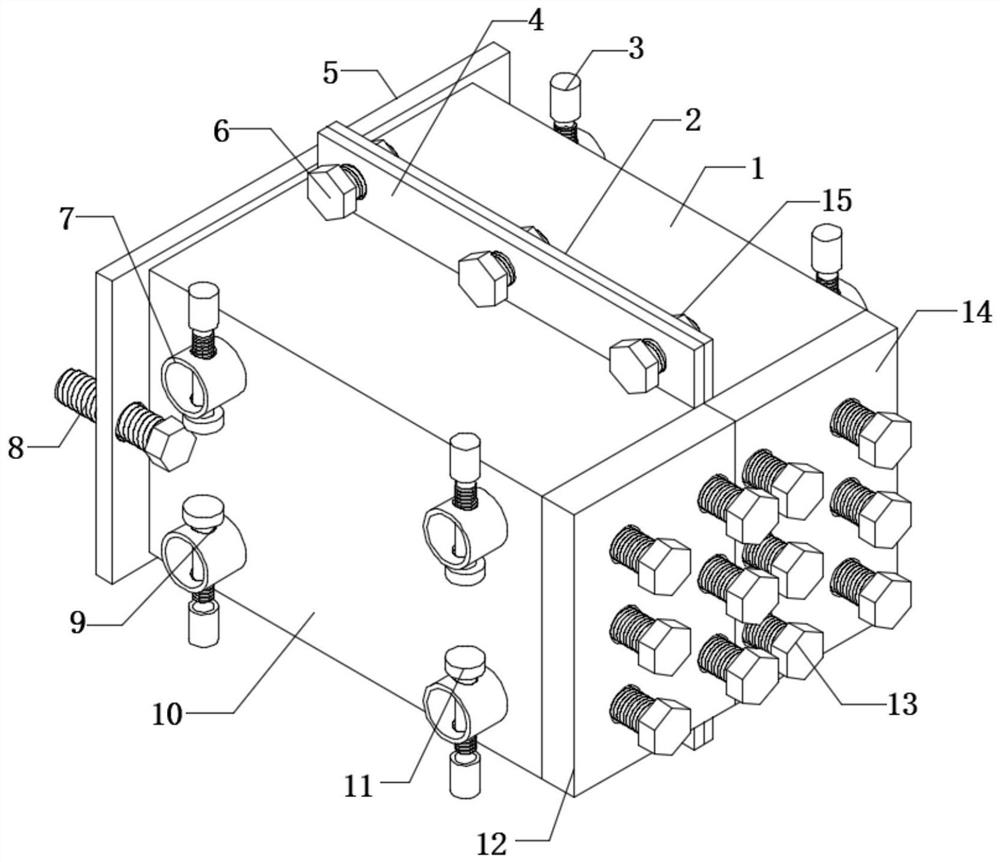

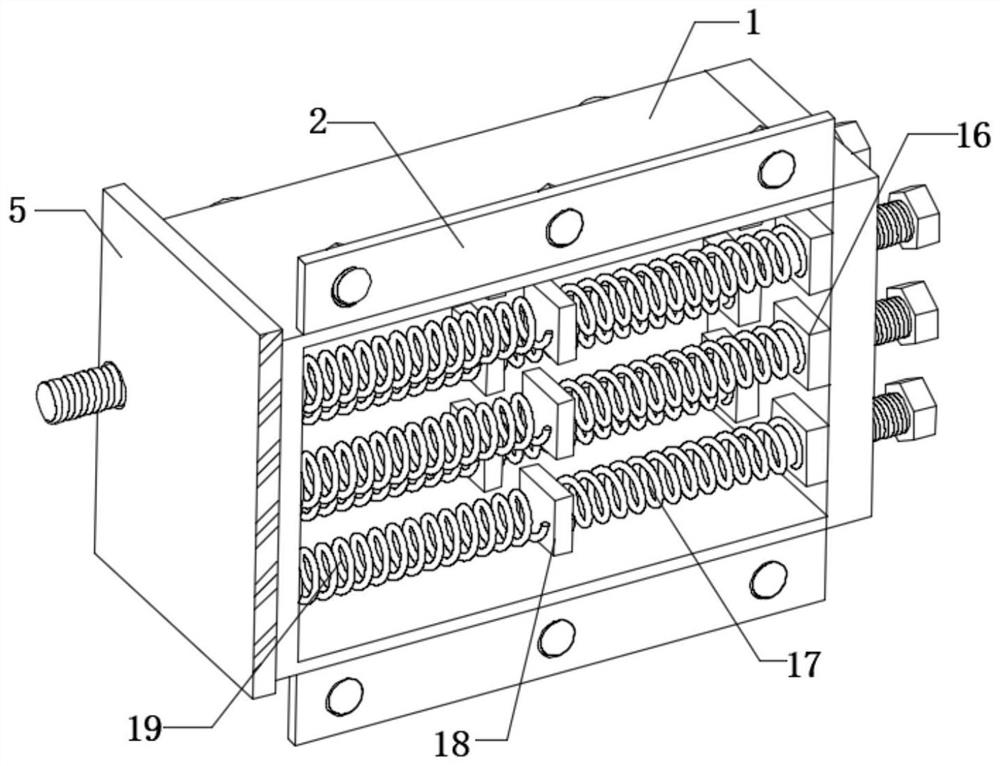

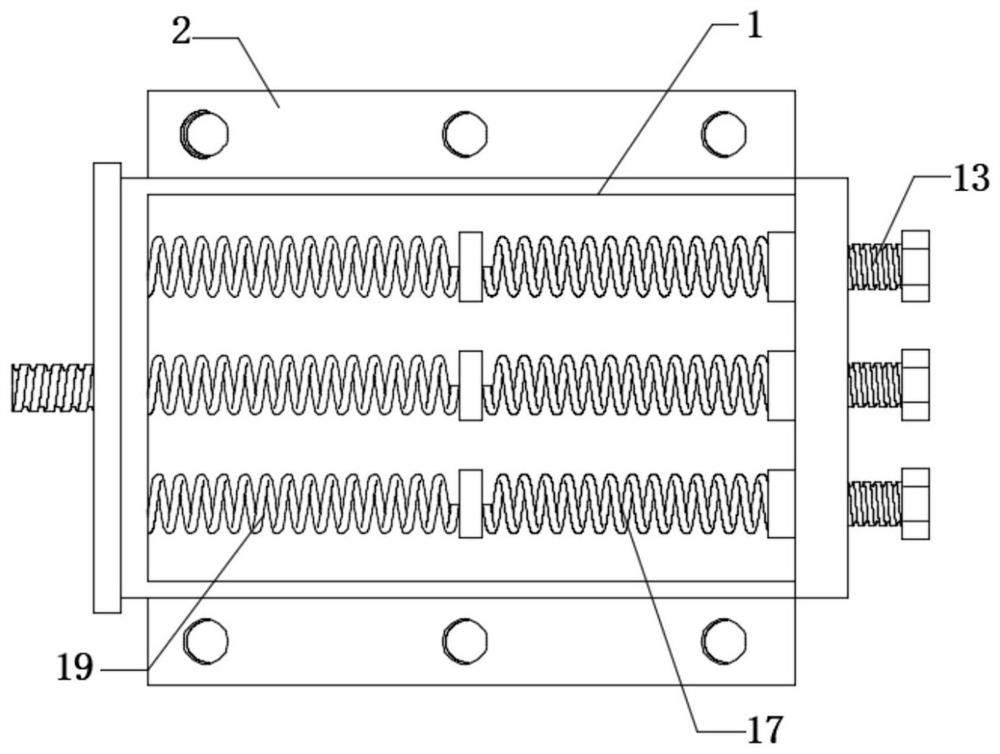

[0029] refer to Figure 1 to Figure 4 As shown, a dynamic vibration absorbing device applied to the tank wall of an oil-immersed transformer is installed on the tank wall of an oil-immersed transformer. The direction is perpendicular to the wall of the oil-immersed transformer box. No. 1 casing 1 and No. 2 casing 10 are connected with a mounting plate 5 at one end close to the tank wall of the oil-immersed transformer, and connected with a limiting plate at one end far away from the tank wall of the oil-immersed transformer.

[0030] Among them, No. 1 housing 1 and No. 2 housing 10 are fixedly connected with No. 2 springs 19 at equal distances from one end of the length of the oil-immersed transformer box wall and the inner wall of the mounting plate 5, and the other end of each No. 2 spring 19 is fixed. An extruded plate 18 is attached. The other end of each pressing plate 18 is fixedly connected with a No. 1 spring 17 , and the other end of each No. 1 spring 17 is fixedly ...

Embodiment 2

[0036] A further improvement is made based on the first embodiment. Due to the large wall area of the oil-immersed transformer, it is generally necessary to install multiple above-mentioned dynamic vibration absorbing devices. In order to fixedly connect a plurality of above-mentioned dynamic vibration absorbing devices as a whole. refer to figure 1 and Figure 4 As shown, the outer walls of the housing No. 1 and the housing No. 2 10 on the opposite side are fixedly connected with connecting cylinders 7 , and the connecting cylinders 7 are provided with through holes 9 radially through them. In order to achieve uniformity, all the through holes 9 are connected up and down and have the same size.

[0037]In this embodiment, four connecting cylinders 7 are arranged on each side, and are distributed near the four corners of the side walls. The two connecting cylinders arranged in pairs on both sides correspond to each other and have different diameters (the outer diameter o...

Embodiment 3

[0039] On the basis of Embodiments 1 and 2, a preliminary vibration-absorbing component is also provided. The preliminary vibration-absorbing assembly includes a number of first connecting plates 20 , second connecting plates 21 and preliminary shock-absorbing springs 22 . Wherein, the outer wall of the mounting plate 5 is equidistantly fixedly connected with a plurality of No. 1 connecting plates 20, which can be distributed in a rectangular array. One end is fixedly connected to the No. 2 connecting plate 21 . When installing the dynamic vibration-absorbing device, the primary vibration-absorbing springs 22 on the No. 1 connection plate 20 and the No. 2 connection plate 21 first play a vibration-absorbing effect, thereby further improving the dynamic vibration-absorbing effect of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com