A film capacitor

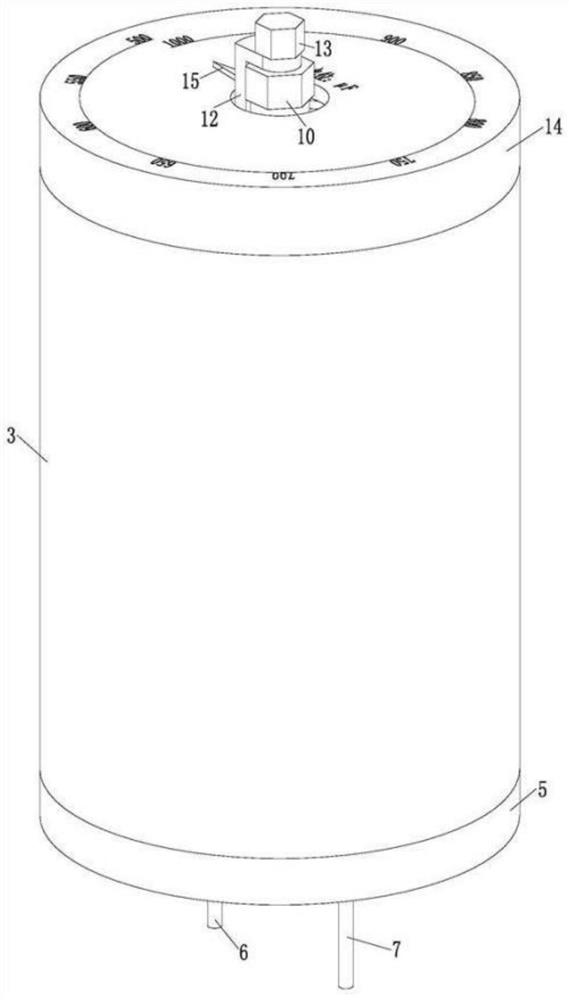

A film capacitor, No. 1 technology, applied in the direction of detailed information of capacitors, variable capacitors, mechanical variable capacitors, etc., can solve problems such as the capacity of film capacitors that cannot be solved, and achieve the goal of improving heat dissipation, enhancing internal structure, and optimizing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

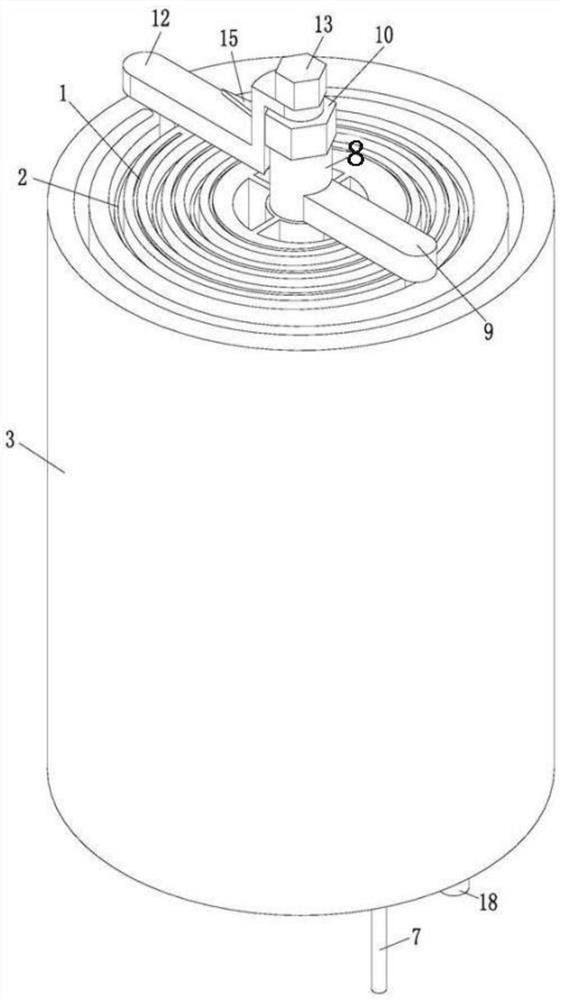

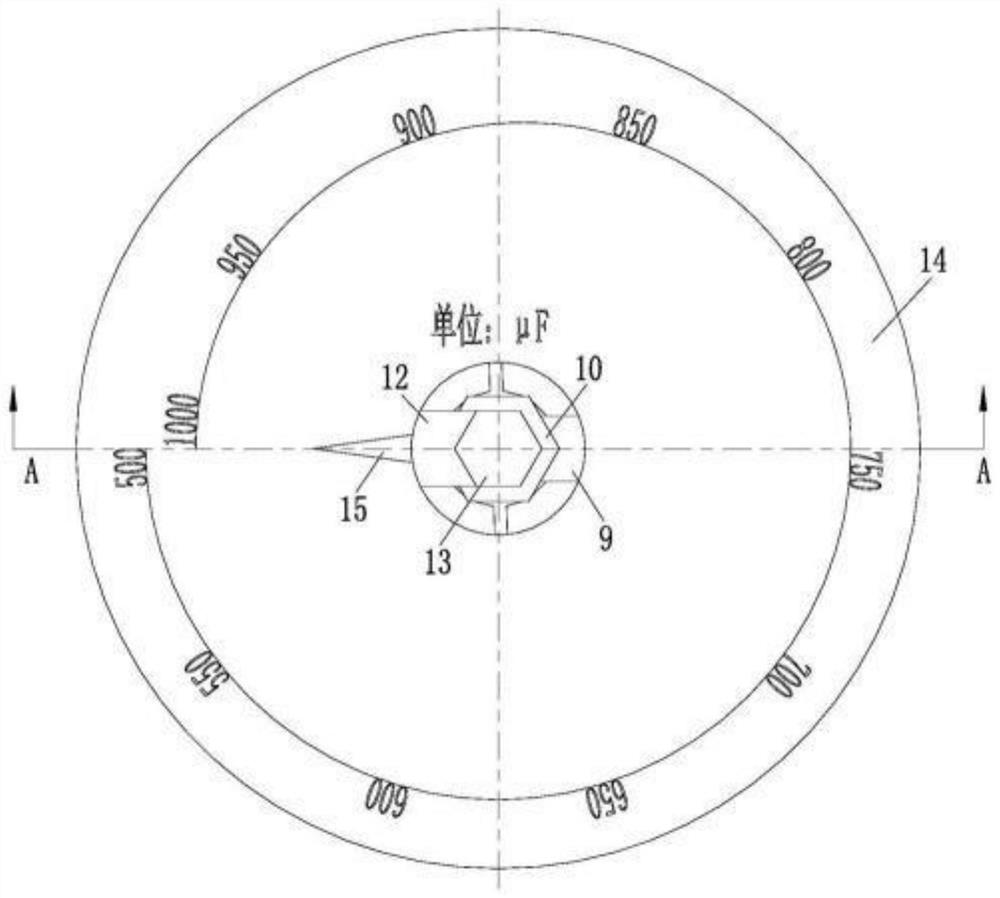

[0026] As an embodiment of the present invention, the center of the base body 3 is rotatably connected to the No. 1 rod 8, the upper part of the No. 1 rod 8 is fixedly connected with a No. 1 plate 9, and a No. 1 groove is arranged inside the No. 1 plate 9 , the inside of the No. 1 groove is slidingly connected to one of the guide rods 4, the upper end of the No. 1 rod 8 is welded with the No. 1 nut 10, and the inside of the No. 1 rod 8 is connected to the No. 2 rod 11 in rotation, so The top of the No. 2 rod 11 is fixedly connected with the No. 2 plate 12, and the inside of the No. 2 plate 12 is provided with a No. 2 groove, and the inside of the No. 2 groove is slidably connected with another guide rod 4. The upper end of the rod 11 is welded with the No. 2 nut 13; when working, if the staff pulls the guide rod 4 by hand to drive the No. 2 electrode foil to intersect with the horizontal plane in the direction of the force generated by the No. 2 through groove, it will cause th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com