Inlaid elastic body sleeve with oblique thorn seam compensation drip seepage pipe belt and its preparation method

A compensating, elastic body technology, applied in botanical equipment and methods, chemical instruments and methods, tubular objects, etc., can solve the problem of poor control of thickness uniformity and hardness, affecting the service life of drip seepage pipe belts, and the amount of drip seepage water Inhomogeneity and other problems, to achieve the effect of good pressure compensation performance, reduced bridging degree, and uniform water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

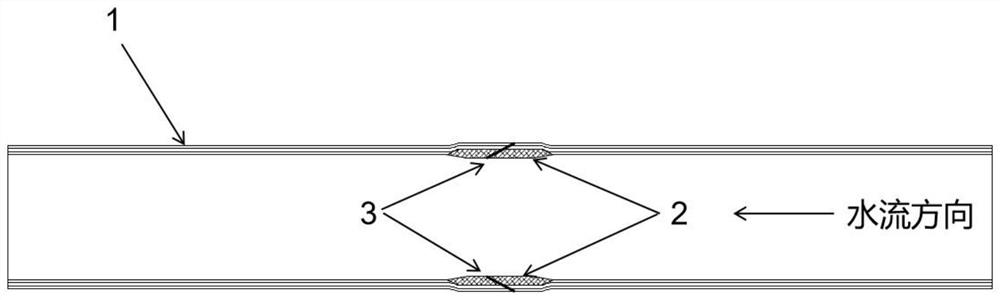

[0033] Example 1 Inlaid elastic body sleeve with oblique slit compensation type drip seepage pipe belt

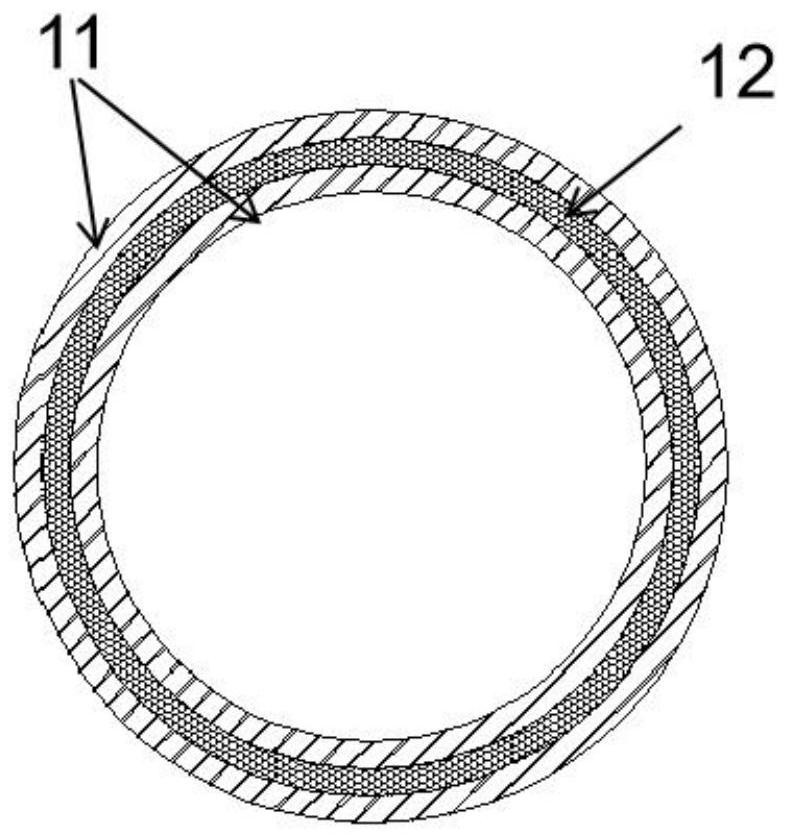

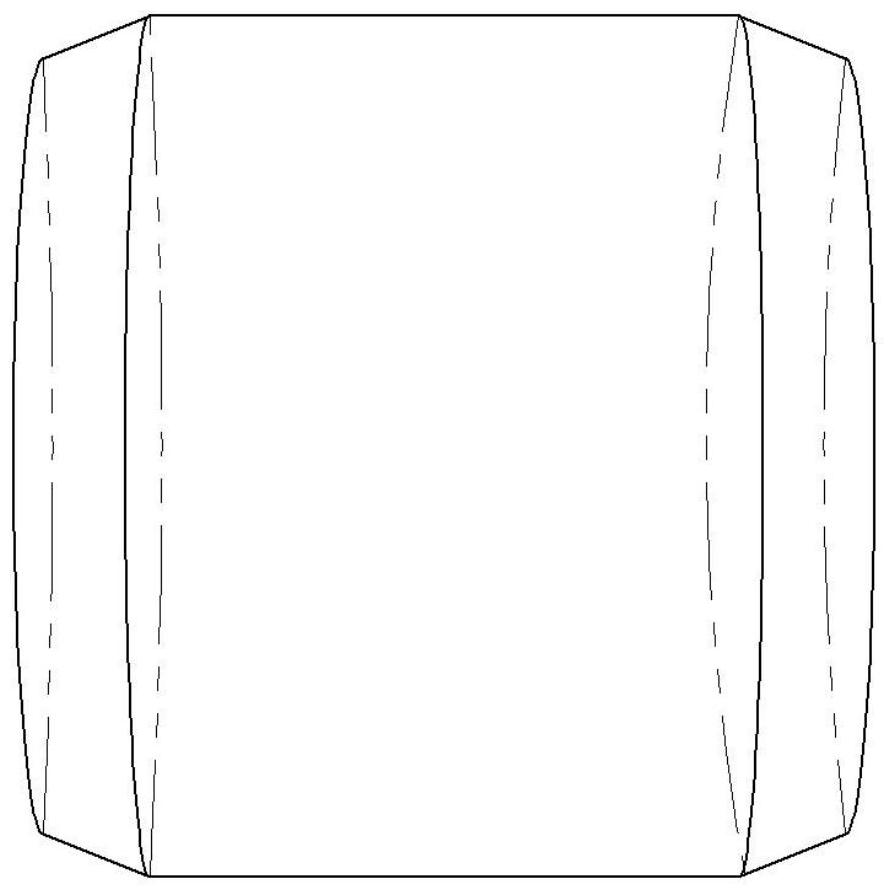

[0034] A compensating seepage pipe belt with oblique puncture seams inlaid with elastic body sleeves, which is composed of a formed pipe belt 1 and an elastic inner sleeve 2, and the formed pipe belt 1 is co-extruded and laminated by A layer 11 and B layer 12 , the outer diameter is 20mm, the A layer 11 is made of EVA material, the B layer 12 is made of polyethylene material, and the structure is A+B+A from inside to outside, the inner A layer 11 has a thickness of 0.2mm, and the B layer 12 has a thickness of 0.5mm. Inner A layer 11 has a thickness of 0.3 mm and a total wall thickness of 1 mm; the EVA material includes by weight: 98% of EVA elastomer, the brand is Taiwan Plastics 7340M, and 2% of carbon black masterbatch; the polyethylene material is by weight Calculated, including: 50% high-density polyethylene (HDPE), brand Maoming Petrochemical E4012, low-density polyeth...

Embodiment 2

[0042] A compensating seepage pipe belt with oblique puncture seams inlaid with elastic body sleeves, which is composed of a formed pipe belt 1 and an elastic inner sleeve 2, and the formed pipe belt 1 is co-extruded and laminated by A layer 11 and B layer 12 , the outer diameter is 20mm, the A layer 11 is made of EVA material, the B layer 12 is made of polyethylene material, and the structure is A+B+A from inside to outside, the inner A layer 11 has a thickness of 0.2mm, and the B layer 12 has a thickness of 0.5mm. The inner A layer 11 has a thickness of 0.5mm and a total wall thickness of 1.2mm; the EVA material includes: EVA elastomer 98%, the trade mark is Mitsui Chemicals P0803, and carbon black masterbatch 2%; the polyethylene material is calculated by weight By weight, including: high-density polyethylene (HDPE) 65%, brand ExxonMobil HD7800P, low-density polyethylene (LDPE) 25%, brand ExxonMobil LD103, mica powder 3%, carbon fiber powder 5% , carbon black masterbatch 2%...

Embodiment 3

[0045] A compensating seepage pipe belt with oblique puncture seams inlaid with elastic body sleeves, which is composed of a formed pipe belt 1 and an elastic inner sleeve 2, and the formed pipe belt 1 is co-extruded and laminated by A layer 11 and B layer 12 , the outer diameter is 20mm, the A layer 11 is made of EVA material, the B layer 12 is made of polyethylene material, and the structure is A+B+A from inside to outside, the inner A layer 11 has a thickness of 0.2mm, and the B layer 12 has a thickness of 0.8mm. The inner A layer 11 has a thickness of 0.5mm and a total wall thickness of 1.5mm; the EVA material includes by weight: 98% of EVA elastomer, the brand is DuPont 260 in the United States, and 2% of carbon black masterbatch; the polyethylene material is by weight By weight, including: 50% high-density polyethylene (HDPE), brand Qilu Petrochemical DGD3479, 40% low-density polyethylene (LDPE), brand LG Chem 500, mica powder 3%, carbon fiber powder 5%, carbon black moth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com