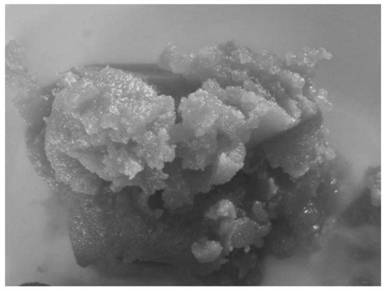

Making process of shredded salted yolk

A production process, the technology of salted egg yolk, which is applied in the production process of salted egg yolk paste, can solve the problems of poor color of egg yolk paste, limitations in sales and transportation, and influence on product marketization, etc., to achieve convenient transportation and storage, and not easy to deteriorate , the effect of low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of preparation technology of salted egg yolk paste, concrete steps are as follows:

[0039] Step 1, select salted eggs with undamaged shells after pickling, remove the shells and take out the whole salted egg yolk;

[0040] In step 2, the salted egg yolk obtained in step 1 is sterilized in a sodium chloride solution with a concentration of 20 wt%, immersed for 1 hour, and drained for later use;

[0041] Step 3: Take out the salted egg yolk after soaking, and dry it at 45°C for 30 minutes.

[0042] Step 4: Spread the tray evenly in one layer, put it in the oven and bake at 140°C for 35 minutes; after the baking is completed, take out the tray and spray cooking wine with 1% of the weight of the egg yolk on the surface of the egg yolk, and cool the salted egg yolk to 80°C;

[0043]Step 5, fully mix salted egg yolk and 9% edible oil in a blender to obtain a uniform mixture of salted egg yolk and edible oil;

[0044] Step 6: Select a colloid mill with a pore size of...

Embodiment 2

[0047] A kind of preparation technology of salted egg yolk paste, concrete steps are as follows:

[0048] Step 1, select salted eggs with undamaged shells after pickling, remove the shells and take out the whole salted egg yolk;

[0049] In step 2, the salted egg yolk obtained in step 1 is sterilized in a 22% sodium chloride solution, submerged for 0.8 hours, and drained for later use;

[0050] Step 3: Take out the salted egg yolk after soaking, and dry it at 42°C for 40 minutes.

[0051] Step 4: spread the tray evenly in one layer, put it in the oven and bake at 150°C for 33 minutes; after the baking is completed, take out the tray and spray cooking wine with 0.8% egg yolk weight on the surface of the egg yolk, and cool the salted egg yolk to 80°C;

[0052] Step 5, fully mix salted egg yolk and 9% edible oil in a blender to obtain a uniform mixture of salted egg yolk and edible oil;

[0053] Step 6: Select a colloid mill with a pore size of 2 to 40 μm, adjust the pore size ...

Embodiment 3

[0056] A kind of preparation technology of salted egg yolk paste, concrete steps are as follows:

[0057] Step 1, select salted eggs with undamaged shells after pickling, remove the shells and take out the whole salted egg yolk;

[0058] In step 2, the salted egg yolk obtained in step 1 is sterilized in a 23% sodium chloride solution, submerged for 0.6h, and drained for later use;

[0059] Step 3, take out the salted egg yolk after soaking, and dry at 40°C for 50 minutes.

[0060] Step 4: spread the tray evenly in one layer, add edible oil accounting for 8% of the mass percentage of salted egg yolk, put it in the oven and bake at 160°C for 30 minutes; after the baking is completed, take out the tray and spray egg yolk with a weight of 0.6% on the surface of the egg yolk % cooking wine, cool the salted egg yolk to 80°C;

[0061] Step 5, thoroughly mixing the salted egg yolk and edible oil obtained in step 4 in a blender to obtain a uniform mixture of salted egg yolk and edibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com