Waste gas purification equipment for garbage incinerator

A garbage incinerator and exhaust gas purification technology, which is applied in the direction of gas treatment, use of liquid separation agent, chemical instruments and methods, etc., can solve the problems of unfavorable environmental protection, air pollution, purification, etc., and achieve a strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

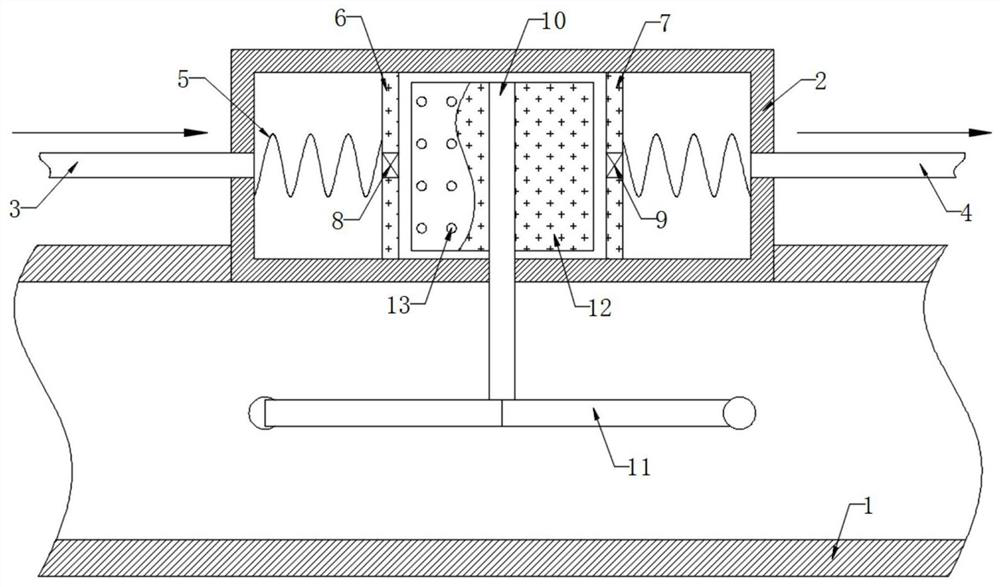

[0020] refer to figure 1 , a waste gas purification device for a waste incinerator, including a purification box 2 fixedly connected to the upper end of a water pipe 1, and further, the water pipe 1 is a cooling water circulation pipe in the incinerator, so that the device can be arranged together with the water pipe 1, which is simple and convenient. Strong practicability, the left side wall of the purification box 2 is connected with the intake pipe 3, the right side wall of the purification box 2 is connected with the exhaust pipe 4, and the inner wall of the purification box 2 is symmetrically fixed and connected with the first magnetic slide plate 6 and the second magnetic slide plate 6 through the telescopic spring 5. Two magnetic slides 7, in the purification box 2, between the first magnetic slide 6 and the second magnetic slide 7 are filled with a purifying agent, further, the purifying agent can be activated carbon adsorbent, and the inner wall of the purification box...

Embodiment 2

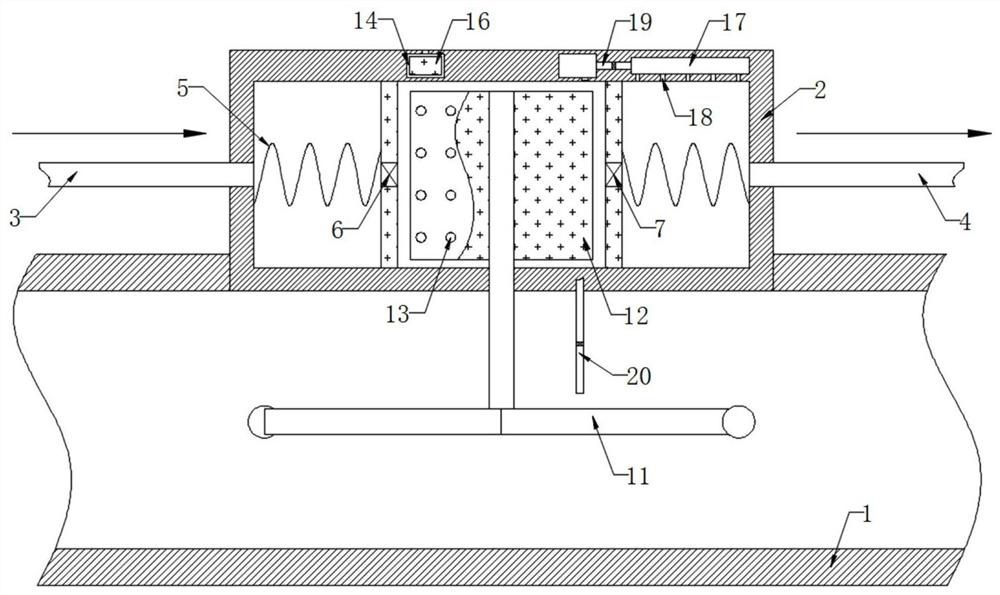

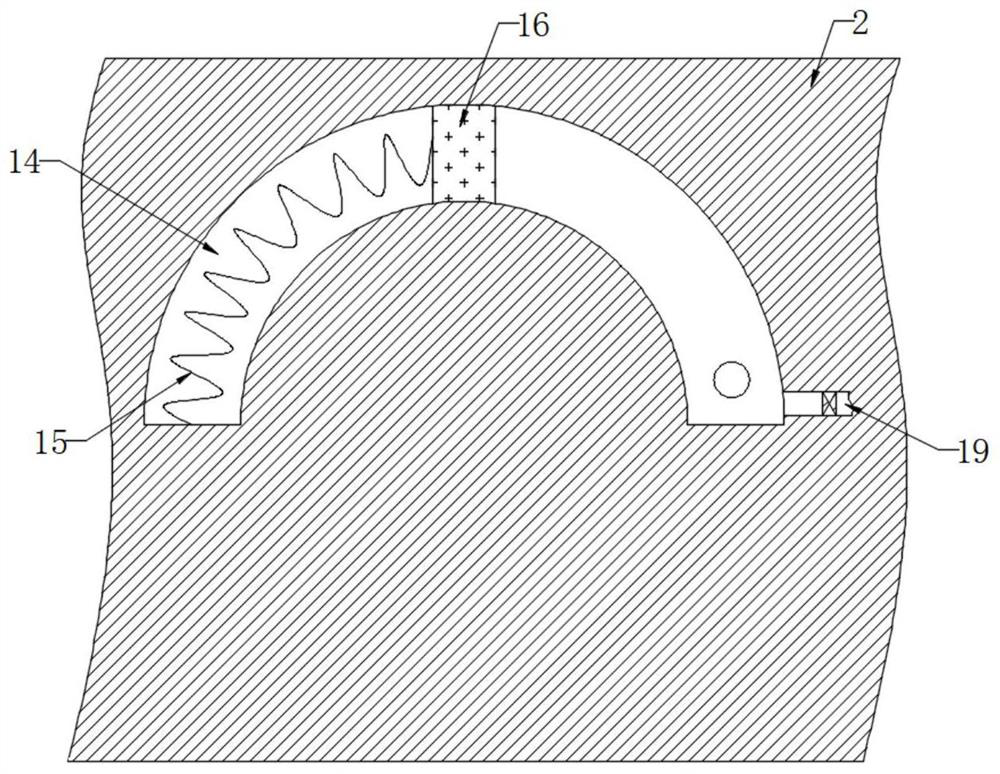

[0024] refer to Figure 2-3 , different from Embodiment 1, the upper end of the purification box 2 is provided with an arc-shaped cavity 14, and the inner wall of the arc-shaped cavity 14 is fixedly connected with a magnetic slide 16 through the return spring 15. Further, the arc-shaped cavity 14 is close to the inner wall of the return spring 15 A through hole is provided to balance the air pressure when the magnetic sliding plug 16 slides on the inner wall of the arc cavity 14. The inner top of the purification box 2 near the exhaust pipe 4 is provided with a cavity 17, and the inner bottom of the cavity 17 is provided with multiple outlets. The hole 18, the end of the arc-shaped cavity 14 away from the return spring 15 is connected to the inner wall of the cavity 17 through the one-way water inlet pipe 19, and the end of the arc-shaped cavity 14 far away from the return spring 15 is connected to the inner wall of the water pipe 1 through the one-way suction pipe 20, which ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com