Laser cutting head adjusting and converting system for laser cutting machine

A technology of laser cutting head and laser cutting machine, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the cutting speed and output power of the laser cutting head cannot be changed in time, the damage to the workpiece and the laser cutting head, and the The cutting head hits the workpiece, etc., to achieve the effect of fast and accurate focusing, fast focusing speed and accurate focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

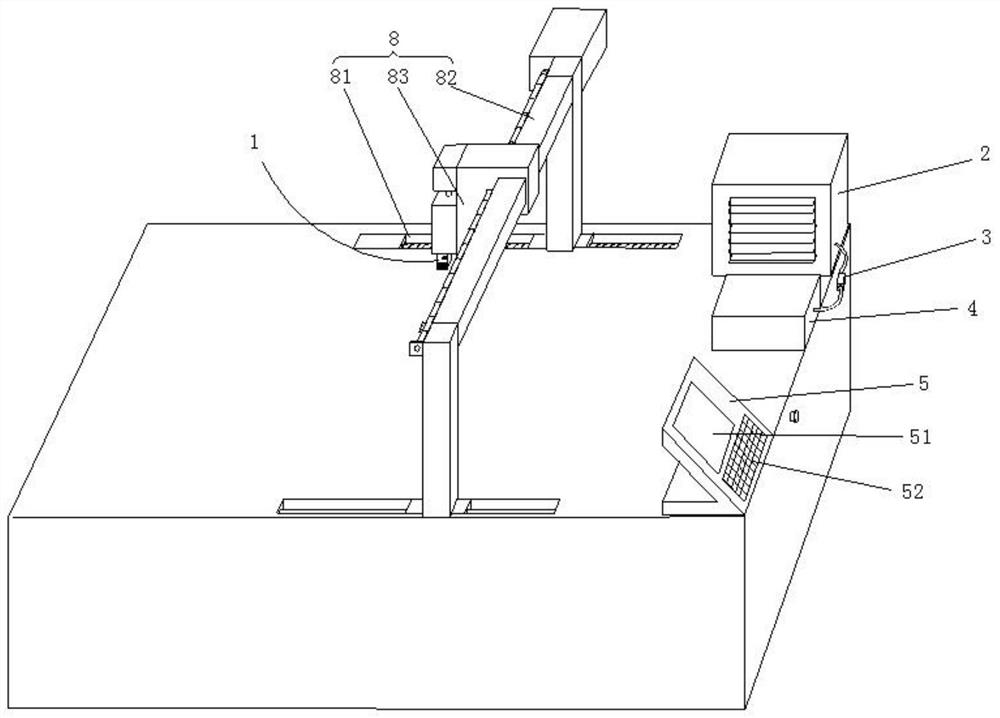

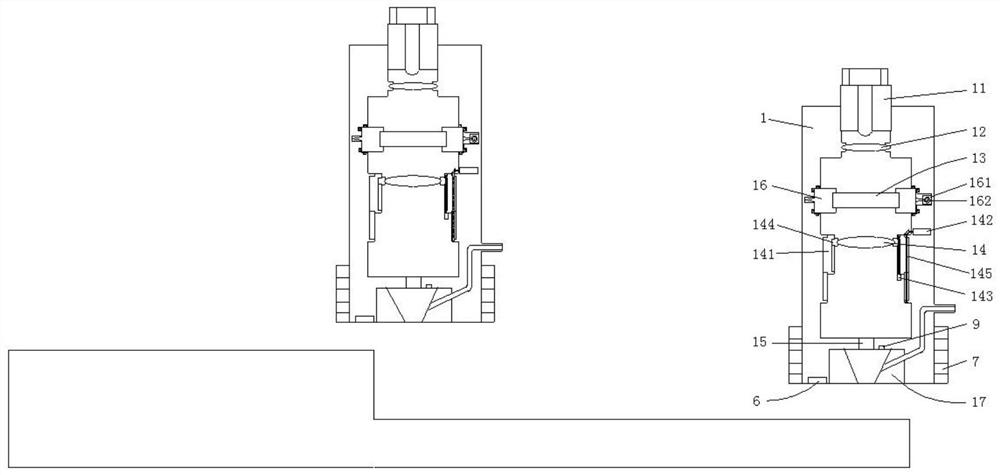

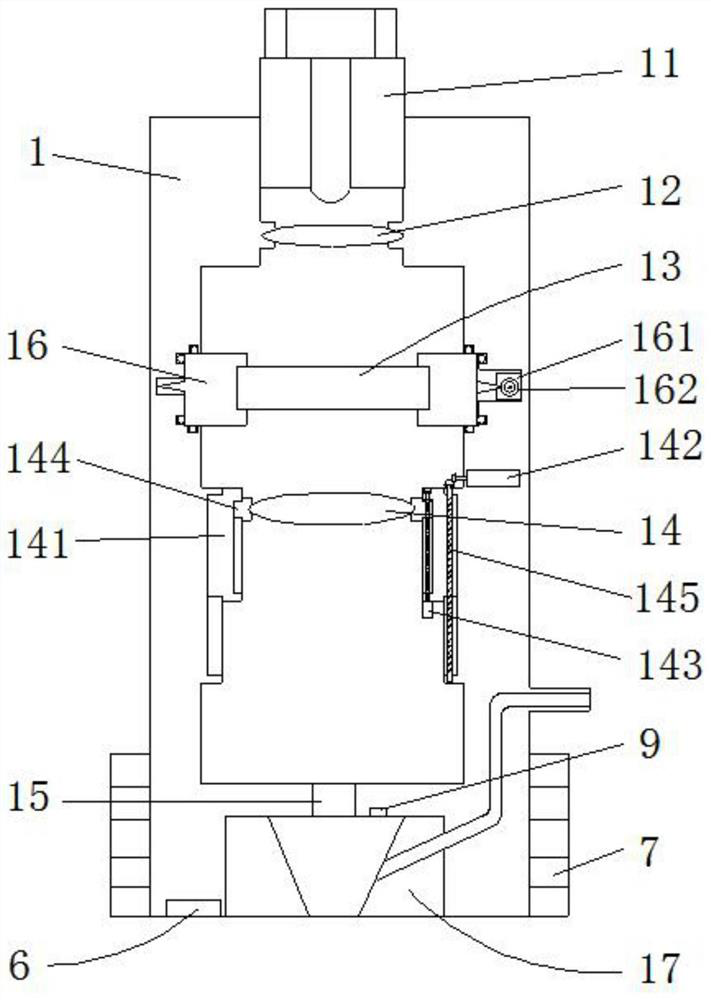

[0026] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 as well as Figure 6 ,in figure 1 A structural schematic diagram of a preferred embodiment of the laser cutting head adjustment conversion system for laser cutting machines provided by the present invention; figure 2 Schematic diagram of obstacle avoidance for laser cutting head body processing workpiece; image 3 for figure 2 The structural schematic diagram of the laser cutting head body shown; Figure 4 for image 3 Schematic diagram of the structure of the focusing mirror shown; Figure 5 for image 3 The structural schematic diagram of the rotating circle and the cylindrical mirror shown; Figure 6 It is a schematic diagram of the laser power adjustment control of the laser cutting head adjustment conversion system for the laser cutting machine provided by ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap