Copper-steel laminated board laser high-precision machining method based on pre-cutting

A processing method and pre-cutting technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low laser absorption rate, damage to the surrounding properties of the slit, and low cutting efficiency, and achieve the goal of improving the laser absorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Example: laser cutting of pre-cut copper-steel laminates

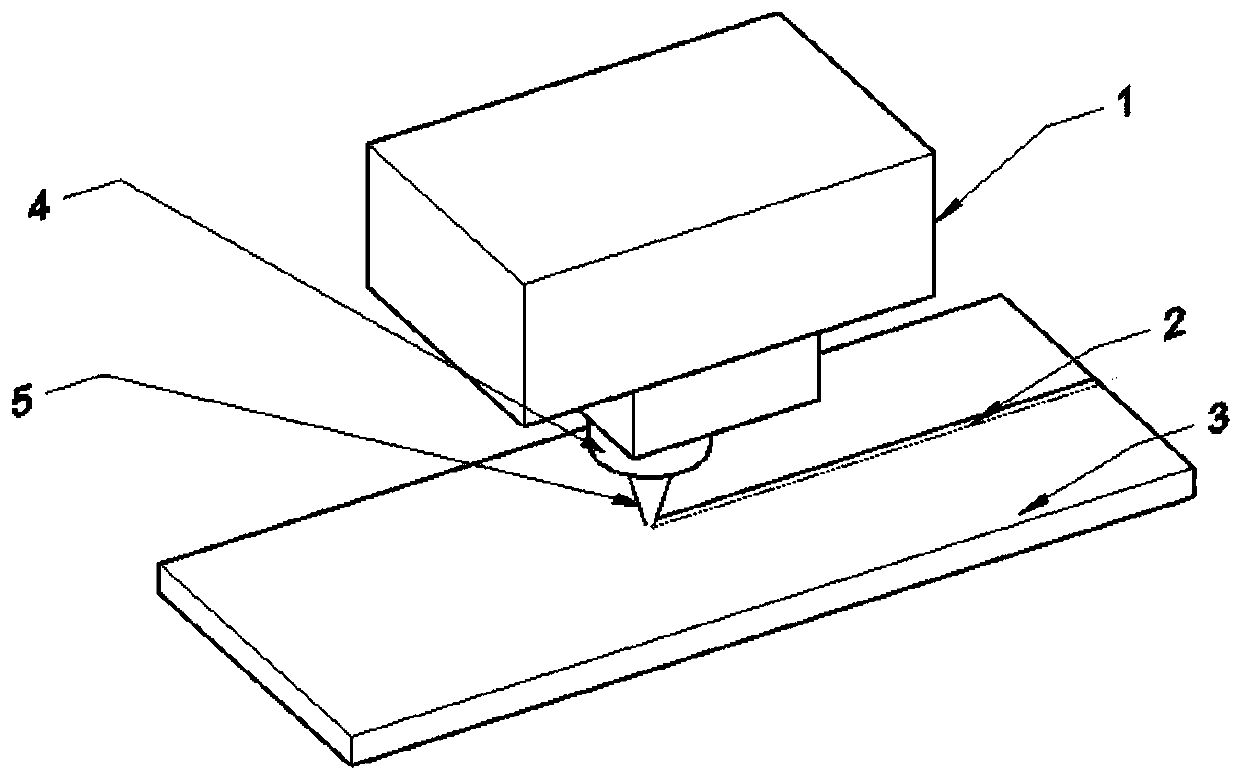

[0036] (1) Place the copper-steel laminate 3 to be processed flat on the laser workbench, reasonably adjust the position of the plate on the workbench according to the workpiece processing requirements, and compact the edge of the plate to ensure that the plate is flat.

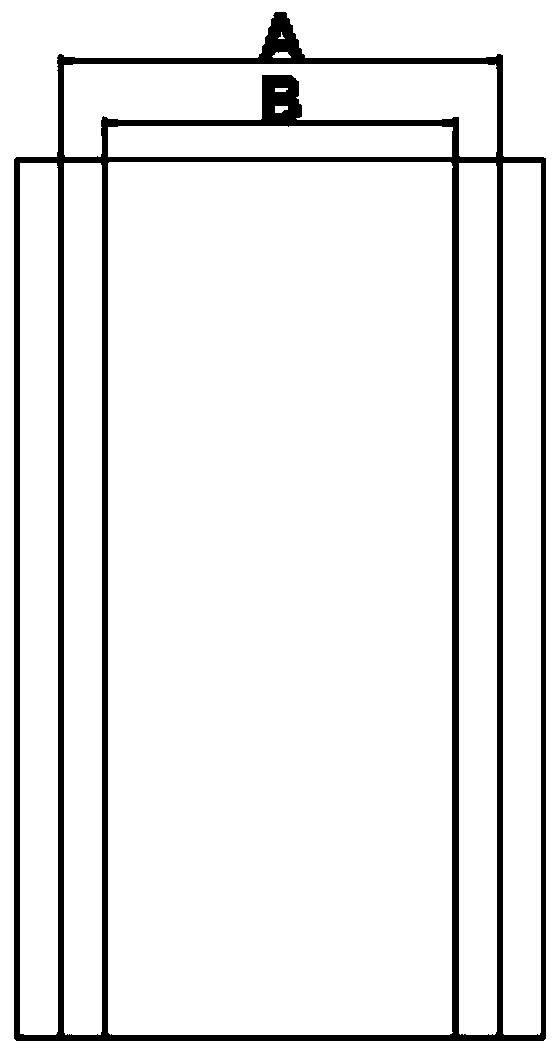

[0037] (2) Install a single-layer air blowing nozzle 4 under the laser head, and adopt coaxial air blowing measures; use an adjustment wrench to set the defocus amount to 0, so that the light spot is focused on the surface of the material, the diameter of the nozzle 4 is 2mm, set the nozzle The distance from the workpiece surface is 0.5mm, and the working mode of the nozzle is follow-up; import the two-dimensional drawing of the workpiece into the fiber laser computer, open the drawing with visual numerical control software, set the cutting frequency to 5000Hz, the peak current to 100%, and open the laser shutter.

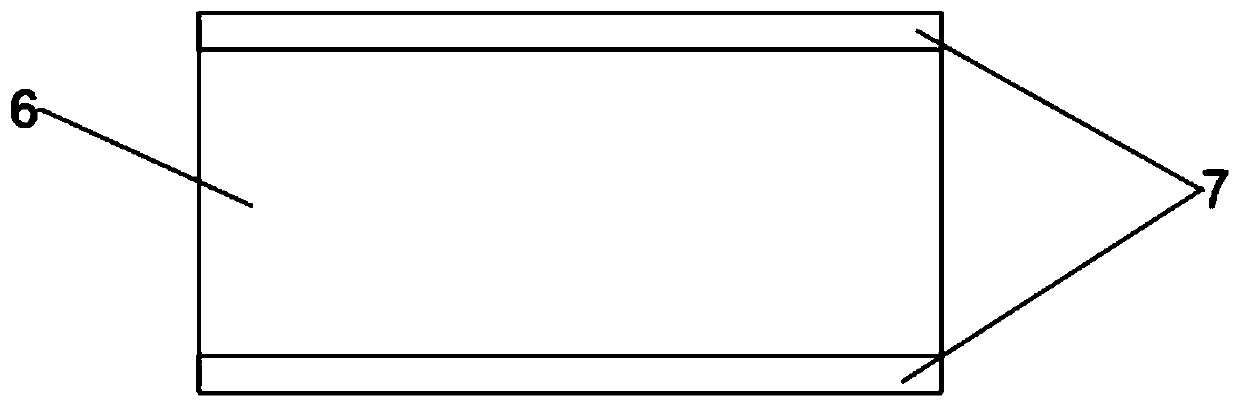

[0038] (3) Pre-cutting metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com