Flexible positioning device and method for slender guide pipe welding structure

A flexible positioning and welding structure technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of positioning effect, low efficiency, waste, etc., and achieve simple clamping process, simple overall structure, and wide flexible range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

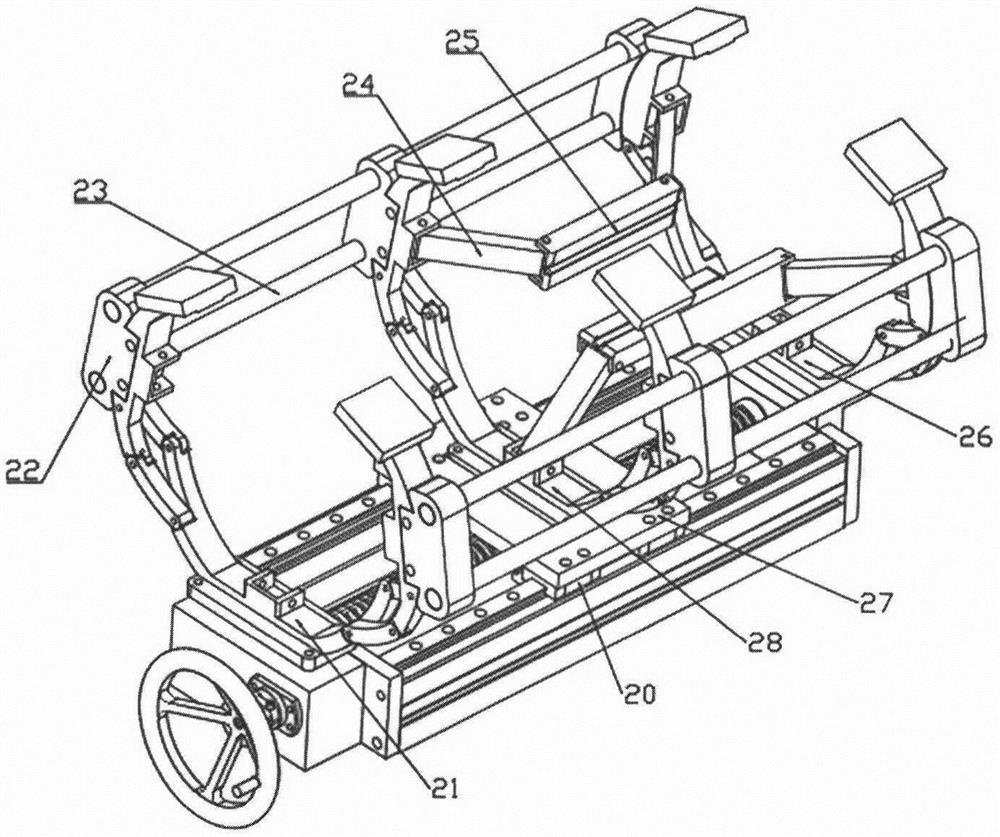

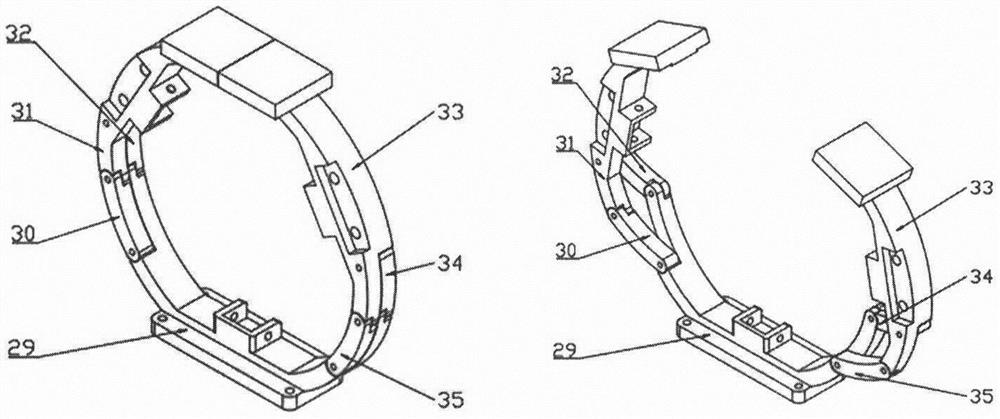

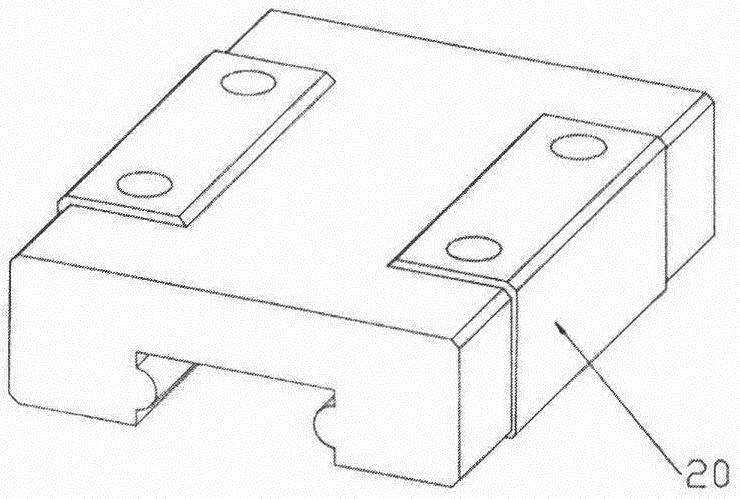

[0019] refer to figure 1 Schematic diagram of the overall structure. The base is used as the foundation, the clamping ring A (21) and the clamping ring B (28) are installed on the base as fixed ends, the clamping ring C (26) cooperates with the mobile platform through the positioning hole (35) of the mobile platform, and the mobile platform passes through The slide block positioning hole (36) is matched with the slide block (20), and the slide block (20) is matched with the guide rails (16, 19), so as to be able to slide freely thereon. Thus, through the rotation of the lead screw (17), the mobile platform (27) can be controlled to move freely on the guide rails (16, 19), and the distance between the clamping ring B (28) and the clamping ring C (26) can be changed. relative distance. Two connecting rods (24) and a clamping plate (25) form a linkage mechanism, and the distance between the clamping plate (25) and the polished rod (23) is changed according to the relative dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com