Synchronous deburring tool for precise match grinding of valve element of servo valve

A deburring and servo valve technology, applied in the field of servo valves, can solve problems such as high working intensity, large flanging burrs, and affecting the test accuracy of the valve core and sleeve, so as to achieve convenient operation, uniform bonding pressure, and avoid outer circle damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

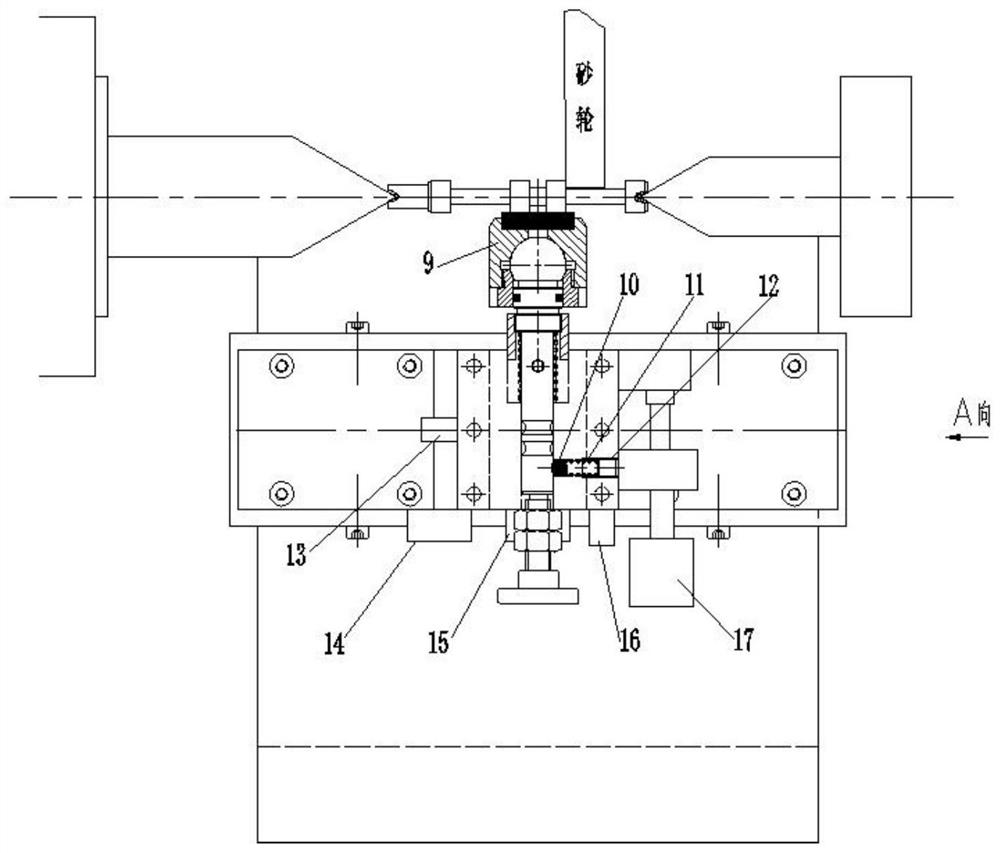

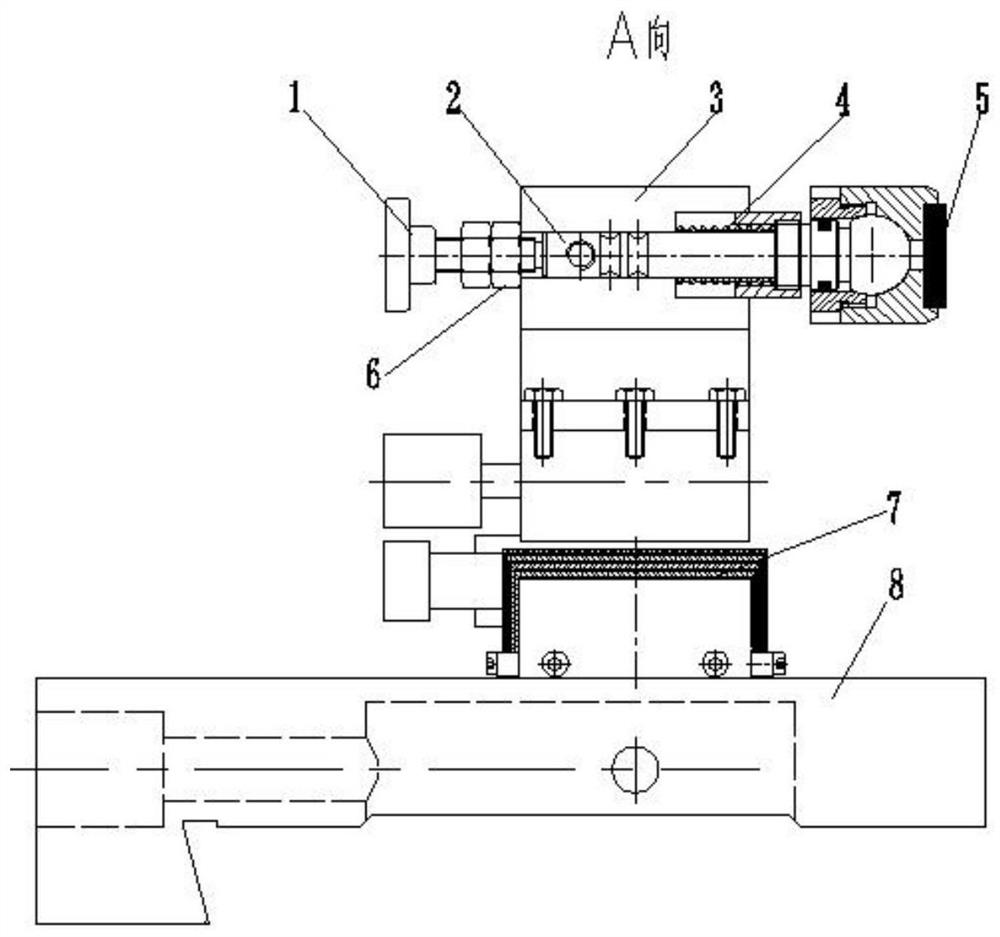

[0014] Such as figure 1 and figure 2 As shown, the servo valve spool of the present invention is precisely equipped with grinding and synchronous deburring tooling, which includes a base 7 installed on the grinding machine bed, and the base is provided with a longitudinal movement mechanism 12, a radial movement mechanism 13 and a radial fine-tuning mechanism 15 , they drive the deburring head assembly to move and adjust the position relative to the spool to be processed. The deburring head assembly includes a sliding shaft seat 3 with a through hole, and a rotatable handle 1 is screwed into the rear end of the through hole. The handle is threadedly connected with the sliding shaft 2, the front end of the sliding shaft protruding from the sliding shaft seat is provided with a universal joint-shaped ball seat 9, the ball seat and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com