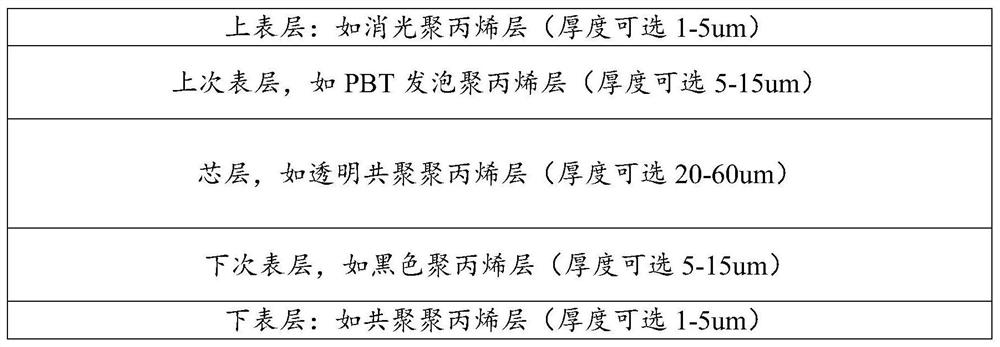

Foamed biaxially oriented thermosensitive film

A biaxially stretched, heat-sensitive film technology, used in layered products, synthetic resin layered products, temperature recording methods, etc., can solve the problems of limited surface wax strength, poor scratch resistance of materials, damage to printer recording needles, etc. Achieve the effect of perfect printing sensitivity, perfect weather resistance and good color development performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

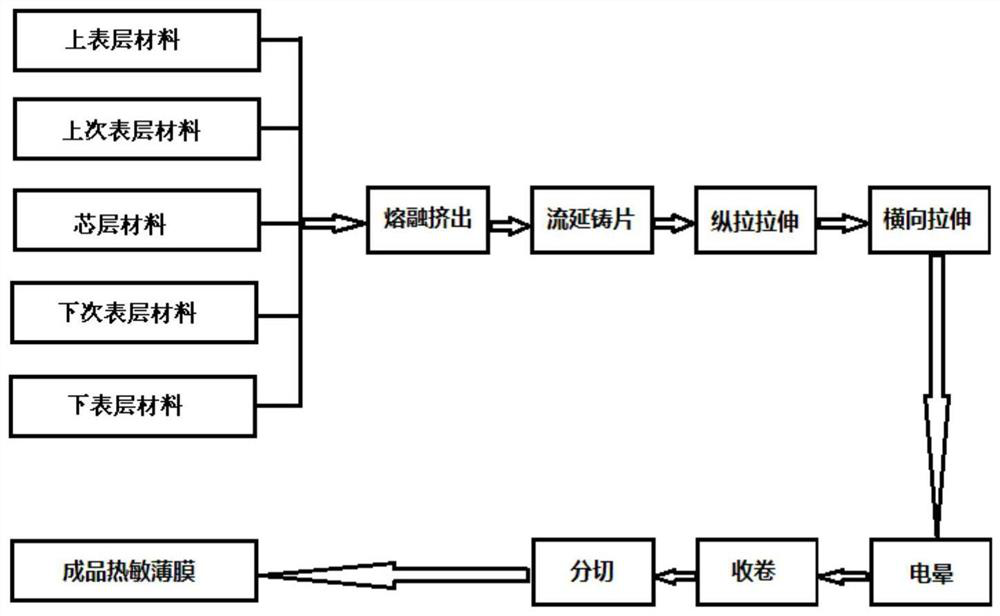

Method used

Image

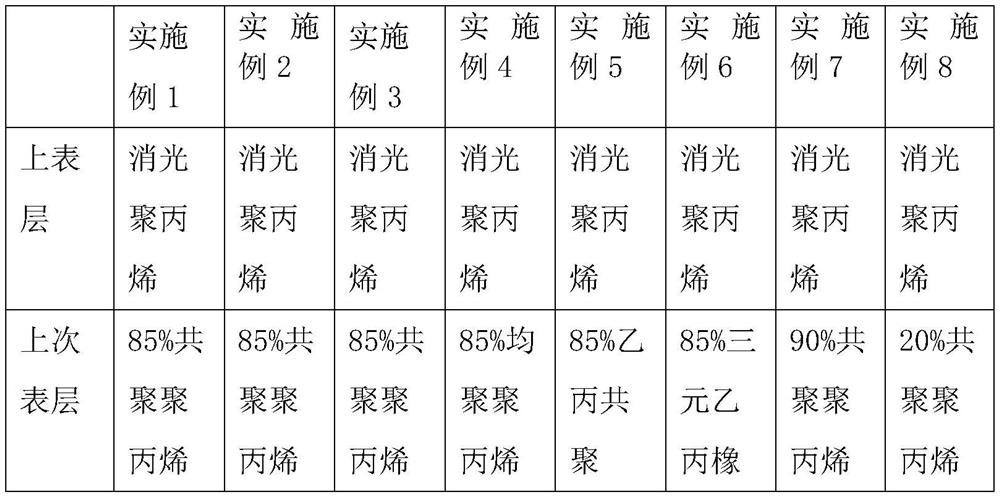

Examples

Embodiment 1

[0041] The preparation method is as follows: Prepare the raw materials of each layer according to the requirements; the matting material is melted by the extruder and extruded as the upper surface layer, the extrusion temperature is 220 degrees, the last extrusion temperature of the surface layer is 220 degrees, the core layer extrusion temperature is 240 degrees, the next time The extrusion temperature of the surface layer is 250 degrees, and the extrusion temperature of the lower surface layer is 220 degrees. After the melts are filtered through the filter respectively, they are merged to form a casting body at five layers using a coat hanger die head, and the temperature of the die head is 250 degrees. The melt enters the water tank for cooling after being cooled into sheets by the quenching roller of the casting machine. The temperature of the quenching roller is 30 degrees, and the temperature of the water tank is 35 degrees. The cooled material enters the longitudinal st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com