Working method of collision energy absorption box with rotary folding concave corners

A technology of collision energy absorption and working method, applied in the field of collision energy absorption boxes, can solve problems such as weak anti-defect ability, structural stability, problems, etc., and achieve the effects of low production cost and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

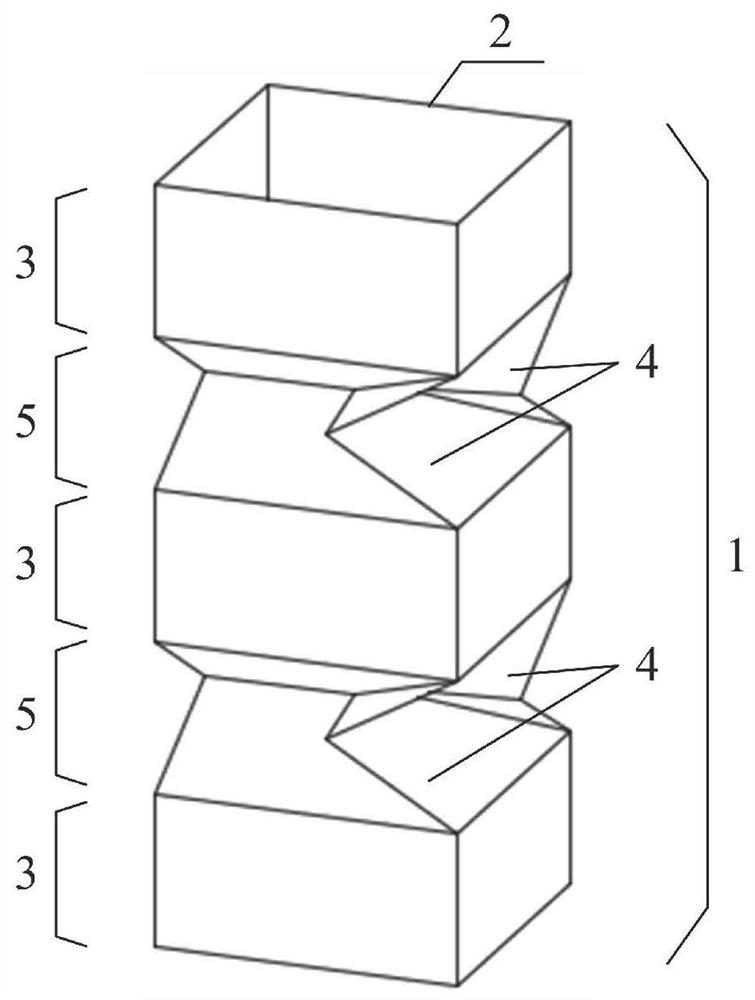

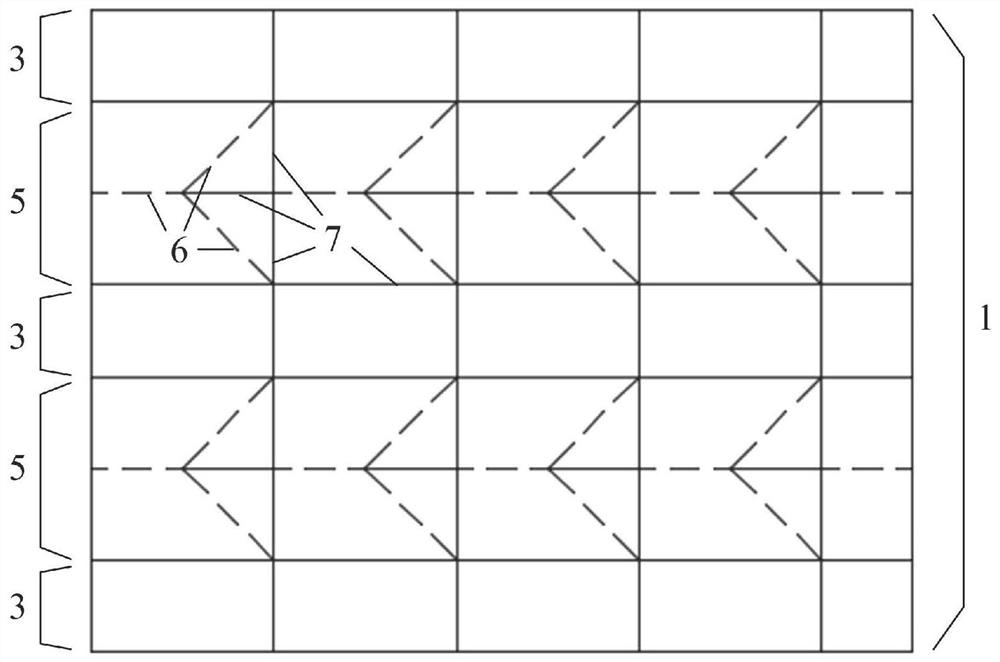

[0035] like figure 1 and figure 2 Shown is a working method of the present invention with a square-section crash box with a rotary folding concave angle, as shown in figure 1 As shown, the square-section impact energy-absorbing box 1 is composed of a plurality of three-dimensional energy-absorbing areas 3 and type I folding energy-absorbing areas 5; Arranged at intervals; the three-dimensional energy-absorbing area 3 is a thin-walled pipe with a polygonal cross-section; the type I folding energy-absorbing area 5 forms circularly arranged rotary folding concave corners through crease lines and combined with rotating folding methods, I The rotary folding concave corner in the type folding energy-absorbing area 5 is a type I folding concave corner 4, and the type I folding concave corner 4 refers to a folding concave corner whose direction of rotation is clockwise; Type I folding energy-absorbing area 5 has a circle of circularly arranged rotary folding concave corners, and ea...

Embodiment 2

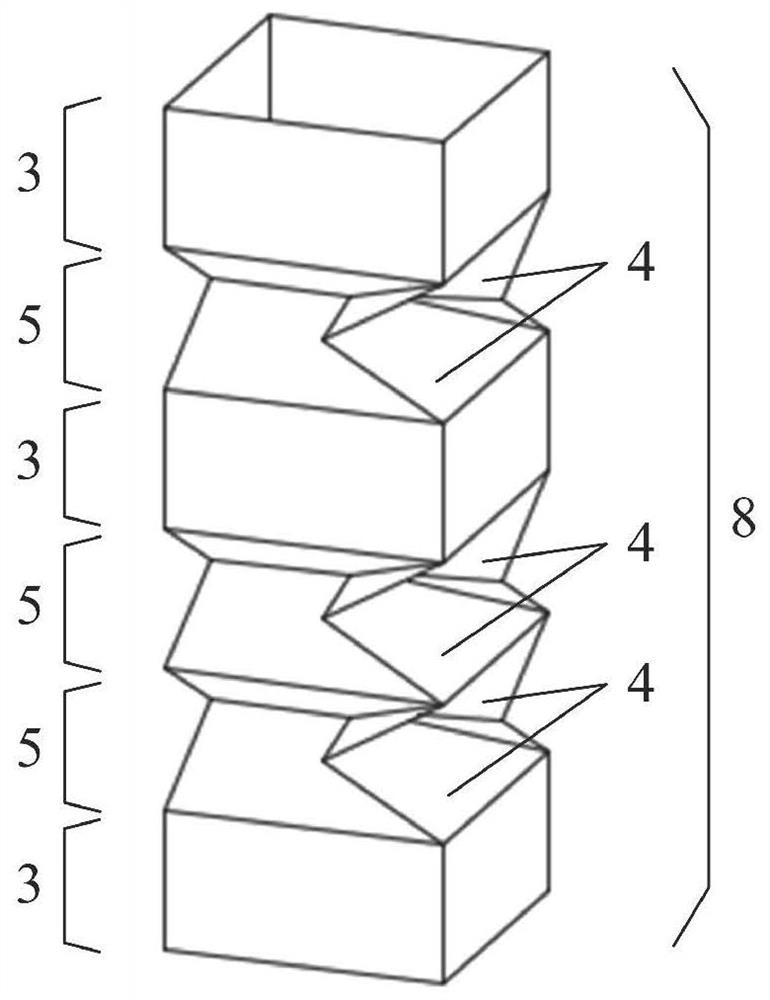

[0038] like image 3 and Figure 4 Shown is a working method of a hybrid type I crash-absorbing box with a rotary folding concave angle of the present invention, as image 3 As shown, the hybrid type I crash energy-absorbing box 8 is composed of a plurality of three-dimensional energy-absorbing areas 3 and type I folding energy-absorbing areas 5, and the three-dimensional energy-absorbing areas 3 and type I folding energy-absorbing areas 5 are arranged crosswise from top to bottom. arranged in a manner. Among them, one type I folded energy absorbing area 5 is arranged between two three-dimensional energy absorbing areas 3 , and two type I folded energy absorbing areas 5 are arranged continuously between the other two three-dimensional energy absorbing areas 3 . Each Type I folding energy-absorbing area 5 has a circle of rotary folding concave angles arranged in a circle, and each Type I folding energy-absorbing area 5 contains four Type I folding concave angles 4; image 3 ...

Embodiment 3

[0041] like Figure 5 and Image 6 Shown is a working method of a hybrid type II crash-absorbing box with a rotary folding concave angle of the present invention, as Figure 5 As shown, the hybrid type II crash energy-absorbing box 9 is composed of a three-dimensional energy-absorbing area 3 , a type-I folding energy-absorbing area 5 and a type-II folding energy-absorbing area 11 . Wherein, the type I folding energy-absorbing area 5 and the type II folding energy-absorbing area 11 are arranged at intervals on the energy-absorbing box. The difference between the Type I folding energy-absorbing area 5 and the Type II folding energy-absorbing area 11 is that the rotary folding concave corner in the Type I folding energy-absorbing area 5 is the Type I folding concave angle 4, and the rotary folding concave angle in the Type II folding energy-absorbing area 11 is The folding reentrant angle is a type II folding reentrant angle 10 , the handing direction of the type I folding reen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com