Collision energy-absorbing box with rotary folding concave corner

A collision energy-absorbing, rotary technology, applied to bumpers, vehicle parts, vehicle safety arrangements, etc., can solve the problems of weak defect resistance, structural stability, and fast impact speed, and achieve low production costs and convenient processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

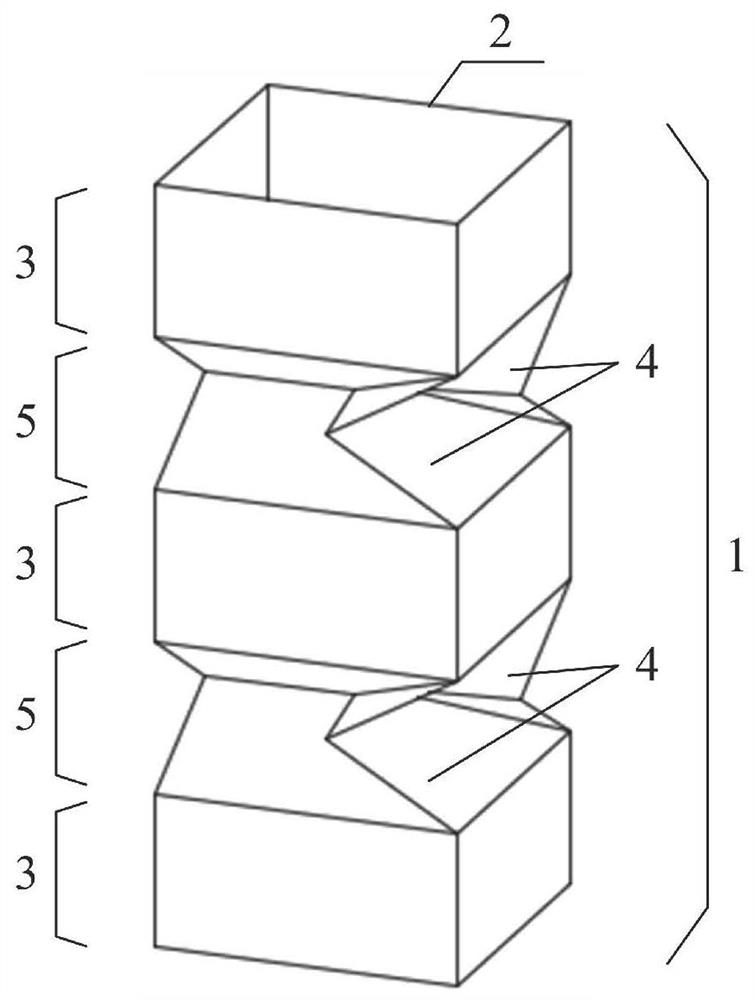

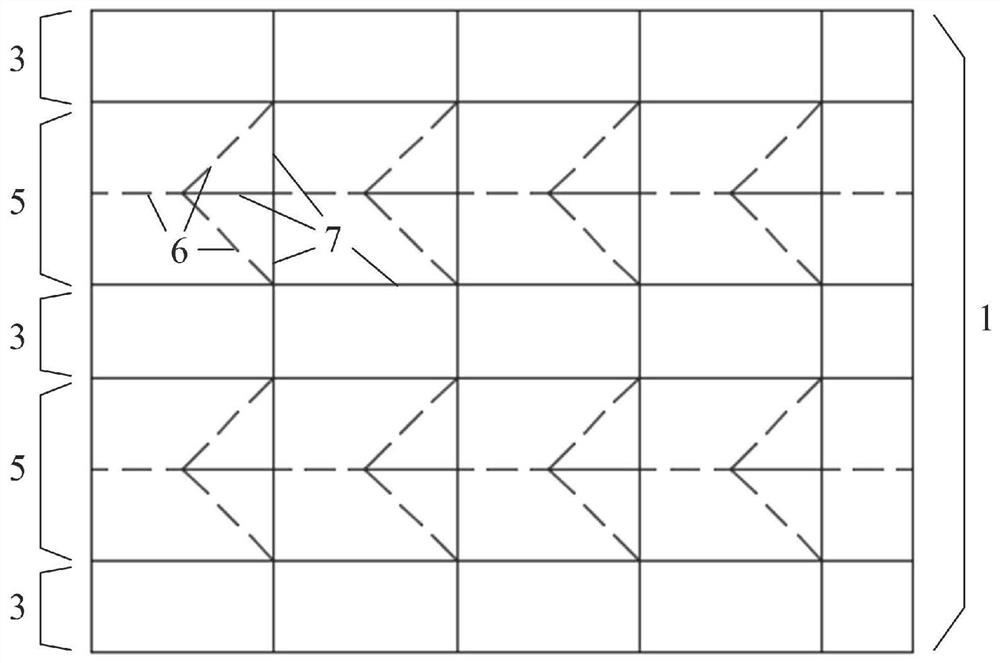

[0033] Example 1: figure 1 and figure 2 It is an embodiment of a crash box with a square section.

[0034] Such as figure 1 As shown, the square-section impact energy-absorbing box 1 is composed of multiple three-dimensional energy-absorbing areas 3 and type I folding energy-absorbing areas 5, and the three-dimensional energy-absorbing areas 3 and type I folding energy-absorbing areas 5 are arranged at intervals from top to bottom. Arranged in different ways; crash boxes of different heights can be obtained by superimposing several three-dimensional energy-absorbing areas and folding energy-absorbing areas along the axial direction. The Type I folding energy-absorbing area 5 forms circularly arranged rotary folding concave corners through crease lines and combined with rotating folding methods. The rotary folding concave corners in the Type I folding energy-absorbing area 5 are Type I folding concave corners 4. Type I folded concave angle 4 refers to the folded concave ang...

Embodiment 2

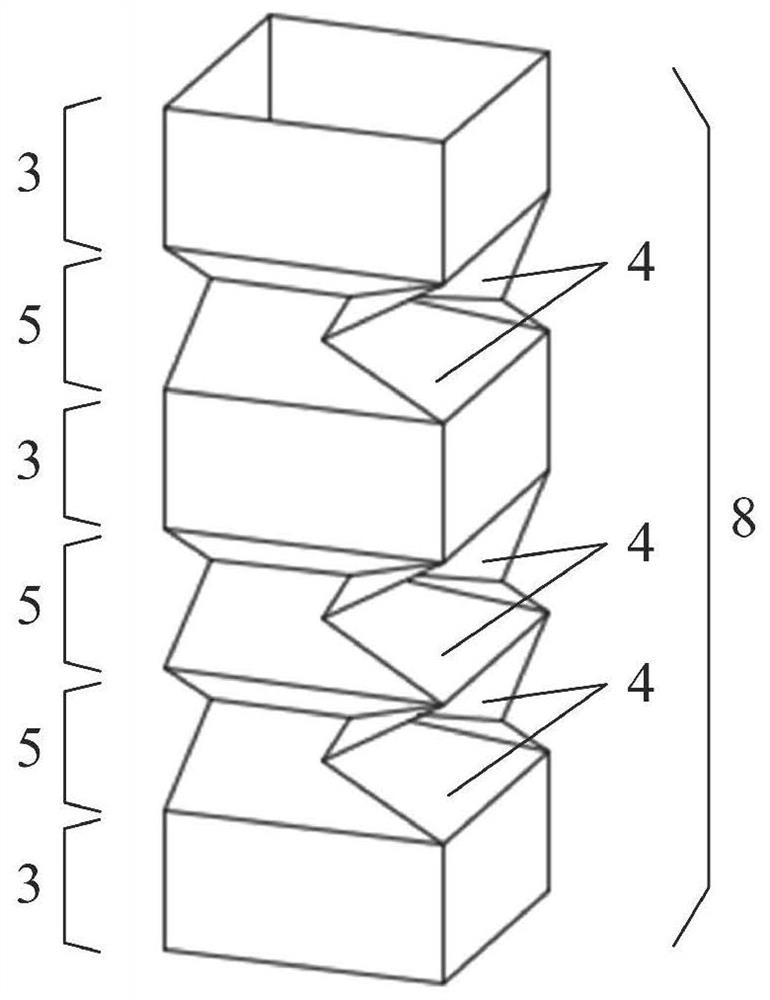

[0035] Example 2: image 3 and Figure 4 It is an embodiment of the hybrid type I crash crash box.

[0036] Such as image 3 As shown, the hybrid type I crash energy-absorbing box 8 is composed of a three-dimensional energy-absorbing area 3 and a type-I folding energy-absorbing area 5, and the three-dimensional energy-absorbing area 3 and the type I folding energy-absorbing area 5 are arranged in a top-to-bottom cross arrangement. Among them, one type I folded energy absorbing area 5 is arranged between two three-dimensional energy absorbing areas 3 , and two type I folded energy absorbing areas 5 are arranged continuously between the other two three-dimensional energy absorbing areas 3 . Each Type I folding energy-absorbing area 5 has a circle of rotary folding concave angles arranged in a circle, and each Type I folding energy-absorbing area 5 contains four Type I folding concave angles 4; Figure 4 As shown, there are three type I folding energy absorbing regions 5 in th...

Embodiment 3

[0037] Example 3: Figure 5 and Figure 6 It is an embodiment of the hybrid type II crash crash box.

[0038] Such as Figure 5As shown, the hybrid type II crash energy-absorbing box 9 is composed of a three-dimensional energy-absorbing area 3 , a type-I folding energy-absorbing area 5 and a type-II folding energy-absorbing area 11 . Among them, the type I folding energy-absorbing area 5 and the type II folding energy-absorbing area 11 are arranged at intervals on the hybrid type II crash energy-absorbing box 9 . The difference between the Type I folding energy-absorbing area 5 and the Type II folding energy-absorbing area 11 is that the rotary folding concave corner in the Type I folding energy-absorbing area 5 is the Type I folding concave angle 4, and the rotary folding concave angle in the Type II folding energy-absorbing area 11 is The folding reentrants are type II folding reentrants 10 , the rotation direction of type I folding reentrants 4 is clockwise, and the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com