Polylactic acid composite material with aggregation-induced emission effect, polylactic acid 3D printing material and preparation method thereof

A technology of aggregation-induced luminescence and composite materials, which is applied in the field of organic light-emitting materials and fused deposition modeling 3D printing materials, can solve the problems of poor interface compatibility between phosphor and polylactic acid matrix, weak luminous intensity, etc., and achieve excellent mechanical properties and biological properties. compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

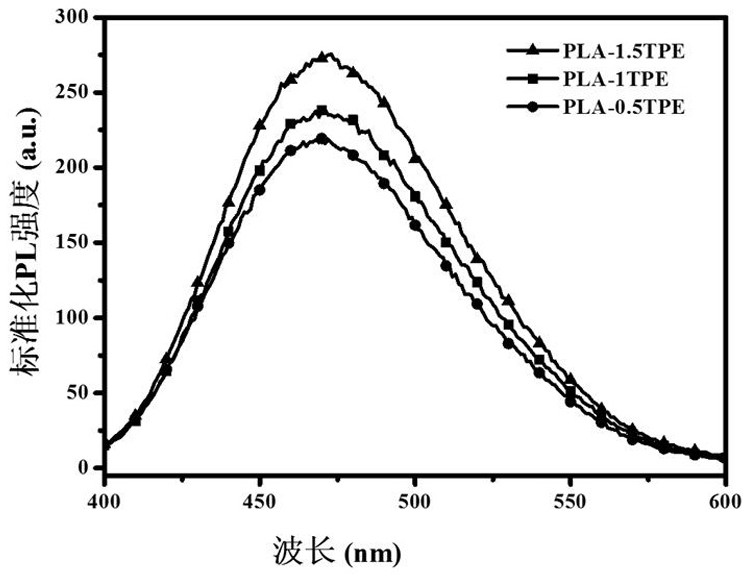

[0039] In this example, the polylactic acid 3D printing material with aggregation-induced luminescent effect is prepared by the following method:

[0040] (1) Soak polylactic acid particles in a closed container filled with dichloromethane, and stir at room temperature at 150rpm until completely dissolved, wherein the mass volume ratio of polylactic acid and dichloromethane is 1:10;

[0041] (2) Add tetraphenylethylene (TPE) powder to the mixed solution in step (1), and stir at 200rpm at room temperature for 0.5h; the mass ratio of tetraphenylethylene (TPE) powder to polylactic acid particles is 1:1;

[0042] (3) Pour the mixed solution obtained in step (2) into an open container, and dry it in an oven at 60°C for 20 hours to obtain a polylactic acid composite material with block AIE effect;

[0043] (4) Put the massive AIE effect polylactic acid composite material obtained in step (3) in a high-speed pulverizer, and pulverize it for 4 minutes to obtain the polylactic acid com...

Embodiment 2

[0050] In this example, the polylactic acid 3D printing material with aggregation-induced luminescent effect is prepared by the following method:

[0051] (1) Soak polylactic acid particles in a closed container filled with dichloromethane, and stir at room temperature at 150rpm until completely dissolved, wherein the mass volume ratio of polylactic acid and dichloromethane is 1:10;

[0052] (2) Add tetraphenylethylene (TPE) powder to the mixed solution in step (1), and stir at 200rpm at room temperature for 0.5h; the mass ratio of tetraphenylethylene (TPE) powder to polylactic acid particles is 3:1;

[0053] (3) Pour the mixed solution obtained in step (2) into an open container, and dry it in an oven at 60°C for 20 hours to obtain a polylactic acid composite material with block AIE effect;

[0054] (4) Put the massive AIE effect polylactic acid composite material obtained in step (3) in a high-speed pulverizer, and pulverize it for 4 minutes to obtain the polylactic acid com...

Embodiment 3

[0058] In this example, the polylactic acid 3D printing material with aggregation-induced luminescent effect is prepared by the following method:

[0059] (1) Soak polylactic acid particles in a closed container filled with dichloromethane, and stir at room temperature at 150rpm until completely dissolved, wherein the mass volume ratio of polylactic acid and dichloromethane is 1:10;

[0060] (2) Add tetraphenylethylene (TPE) powder to the mixed solution in step (1), and stir at 200rpm at room temperature for 0.5h; the mass ratio of tetraphenylethylene (TPE) powder to polylactic acid particles is 5:1;

[0061] (3) Pour the mixed solution obtained in step (2) into an open container, and dry it in an oven at 60°C for 20 hours to obtain a polylactic acid composite material with block AIE effect;

[0062] (4) Put the massive AIE effect polylactic acid composite material obtained in step (3) in a high-speed pulverizer, and pulverize it for 4 minutes to obtain the polylactic acid com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com