A polymer with aggregation-induced luminescent effect and its preparation method

An aggregation-induced luminescence and polymer technology, applied in the field of luminescent polymer materials, can solve the problems that have not been reported in the field of polymer synthesis, and achieve excellent aggregation-induced luminescence effect, strong operability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

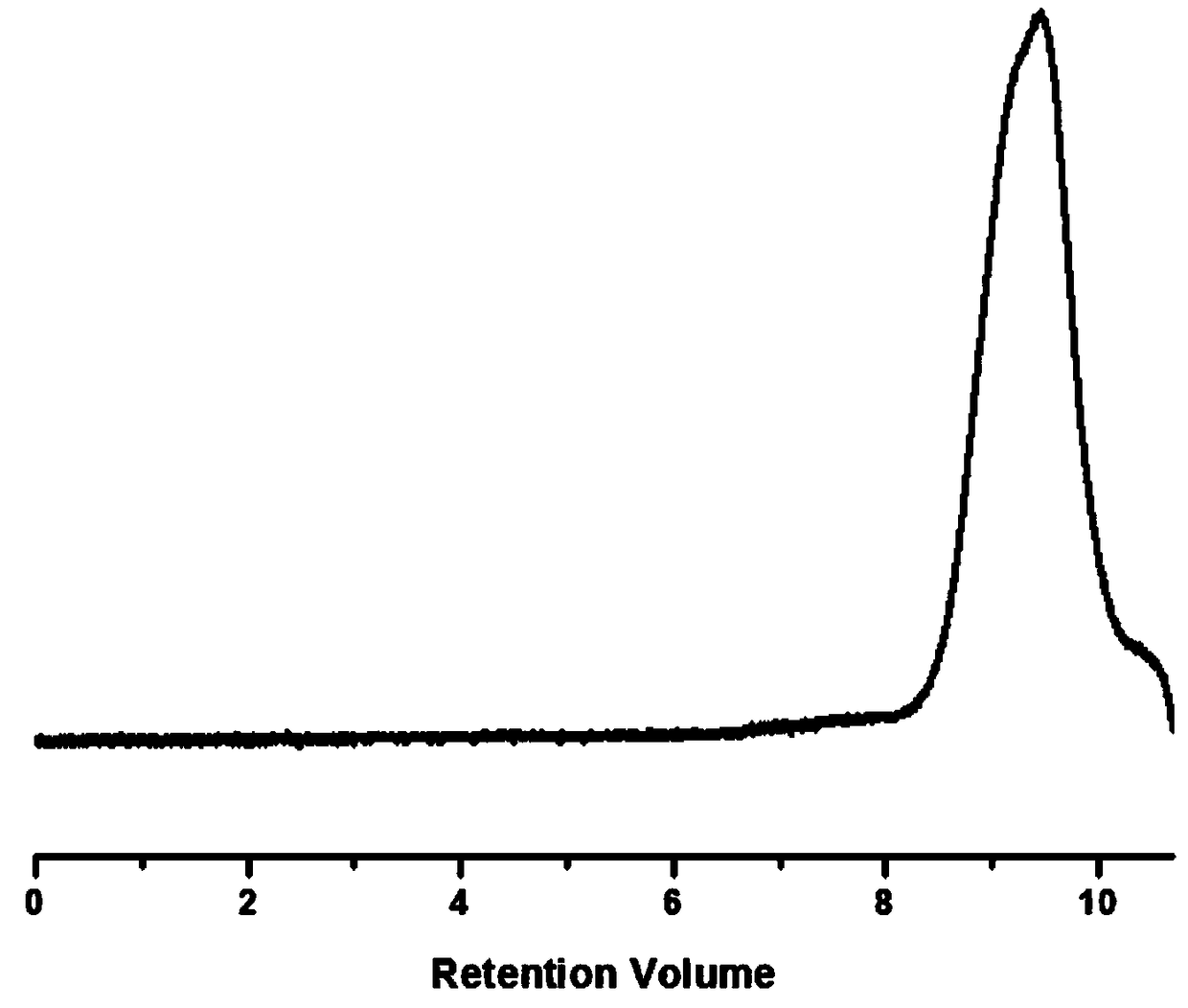

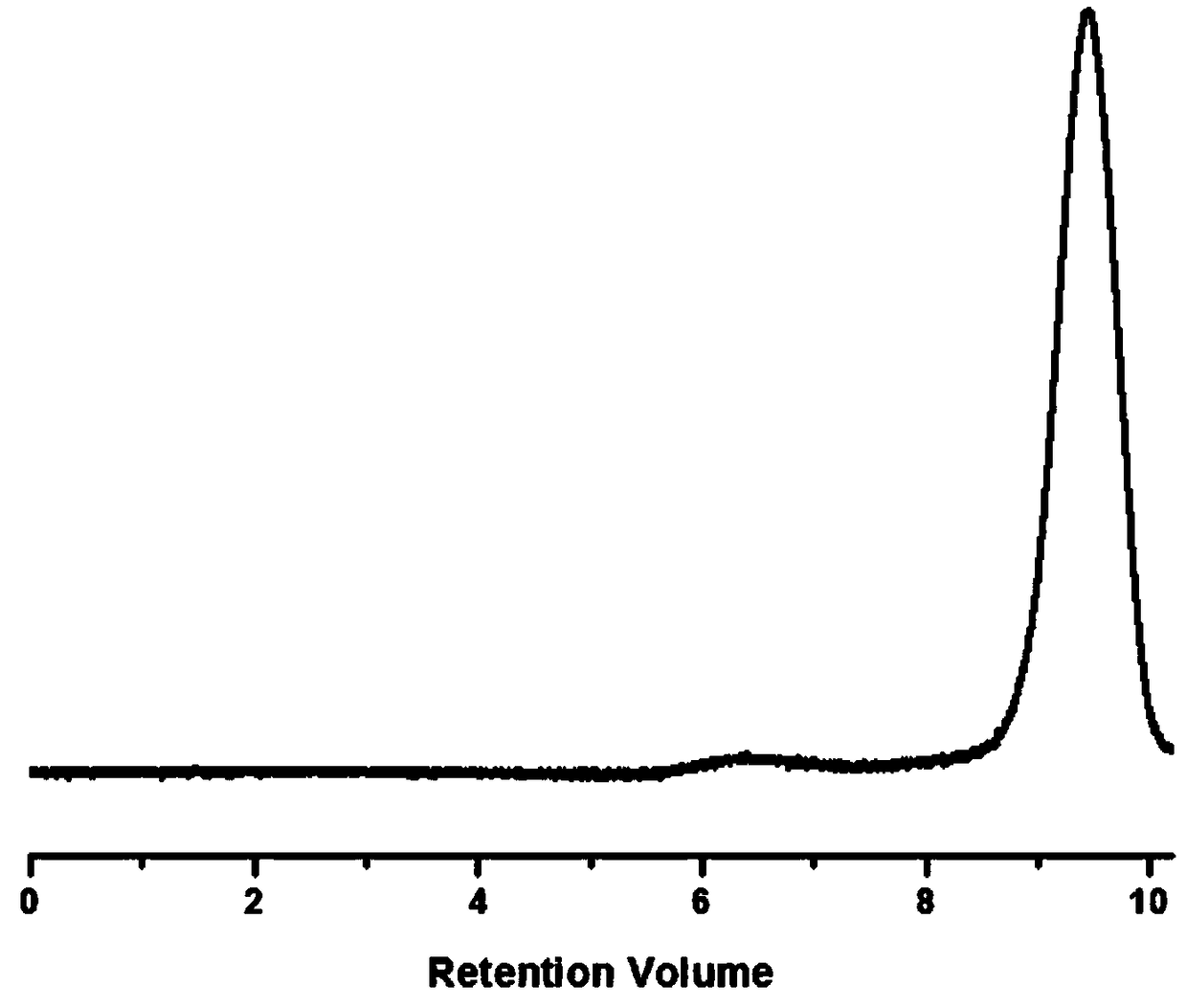

[0049] The above-mentioned preparation method of a polymer with aggregation-induced luminescence effect, the reaction monomer is 4-bromo-benzophenone, and the one-pot Barbier self-condensation polymerization reaction is adopted, and the prepared polymer has better aggregation-induced luminescence effect , including the following preparation process:

[0050]

[0051] (1) Synthesis of crude polymer products

[0052] Take magnesium chips 1.2 times the amount of 4-bromo-benzophenone and add them to a double-necked flask with a rubber stopper on the branch, connect the condenser tube and the exhaust joint in turn, and apply vacuum grease to each joint to ensure airtightness Good performance, repeat the process of vacuuming, blowing, cooling, and nitrogen gas three times, and finally connect the nitrogen balloon to ensure that the system is anhydrous and nitrogen atmosphere. Inject 10-40mL solvent from the rubber stopper, under magnetic stirring, disperse the magnesium chips ev...

Embodiment 1

[0061] The present embodiment provides a kind of 4-bromo-benzophenone barbier self-condensation polymerization to prepare the method for macromolecule, comprises the steps:

[0062] (1) Synthesis of crude polymer products

[0063] Take a 100mL double-necked flask, coat the mouth with vacuum grease, plug it with a rubber stopper, and wrap it tightly with insulating tape to ensure good airtightness. Add magnesium chips (0.288g, 0.012mol) into the double-necked flask from the straight mouth, add magnets, and connect the condenser tube and straight air extraction joint in sequence (all joints need to be coated with vacuum grease and clamped with plastic clips). Repeat the process of evacuating, blowing, cooling, and passing nitrogen three times. After passing the nitrogen gas for the last time, close the straight-shaped air extraction joint, connect a balloon filled with nitrogen gas, and then open the plug of the straight-shaped air extraction joint to make the nitrogen gas comm...

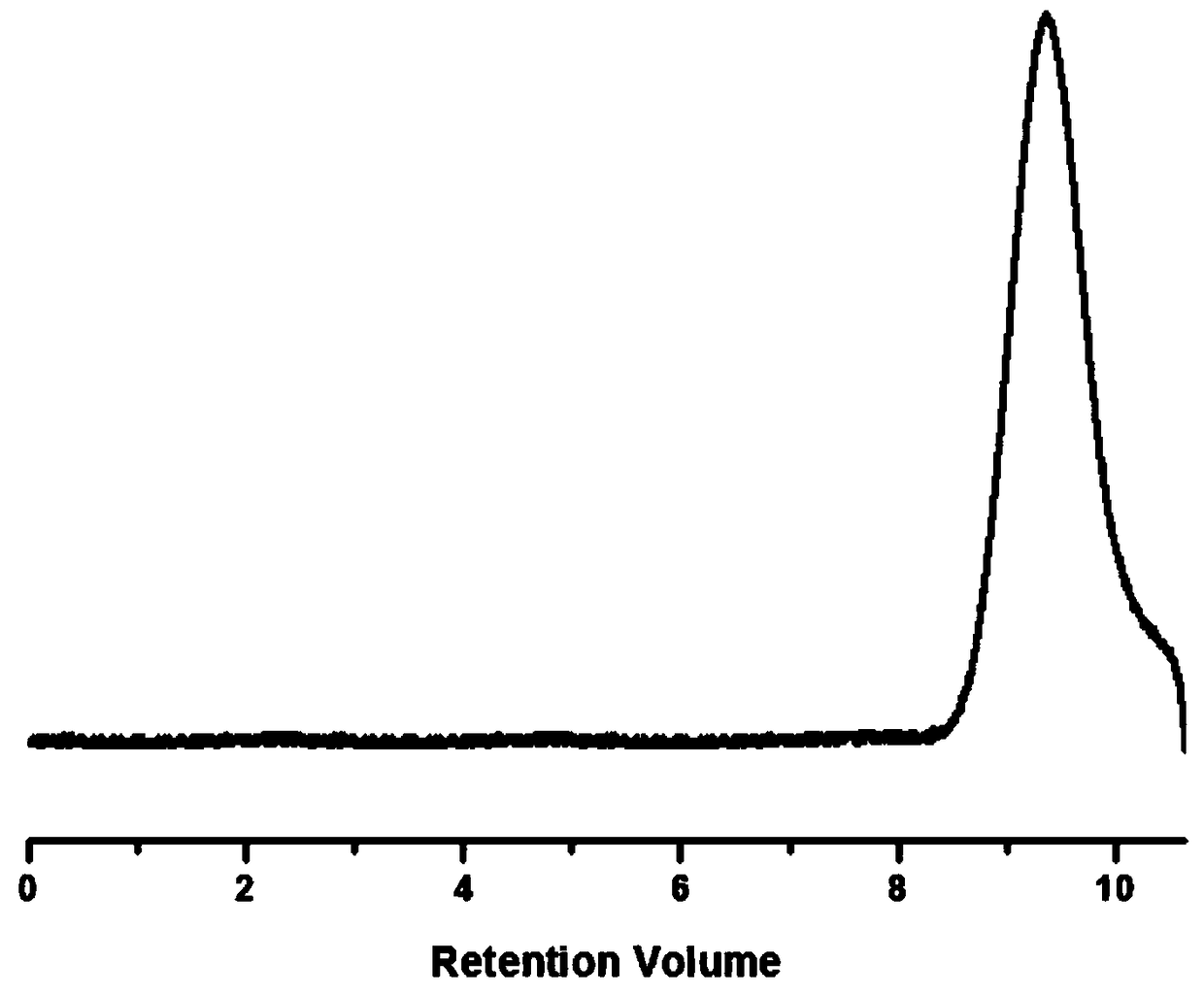

Embodiment 2

[0069] The present embodiment provides a kind of 4-bromo-benzophenone barbier self-condensation polymerization to prepare the method for macromolecule, comprises the steps:

[0070] (1) Synthesis of crude polymer products

[0071] Take a 100mL double-necked flask, coat the mouth with vacuum grease, plug it with a rubber stopper, and wrap it tightly with insulating tape to ensure good airtightness. Add magnesium chips (0.288g, 0.012mol) into the double-necked flask from the straight mouth, add magnets, and connect the condenser tube and straight air extraction joint in sequence (all joints need to be coated with vacuum grease and clamped with plastic clips). Repeat the process of evacuating, blowing, cooling, and passing nitrogen three times. After passing the nitrogen gas for the last time, close the straight-shaped air extraction joint, connect a balloon filled with nitrogen gas, and then open the plug of the straight-shaped air extraction joint to make the nitrogen gas comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com