Shear wall structure

A shear wall and power arm technology, applied in the direction of walls, building components, building structures, etc., can solve the problem of not being able to fully utilize the energy dissipation capacity of the damper, achieve strong applicability, and improve the bearing capacity and energy dissipation capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention is described in detail:

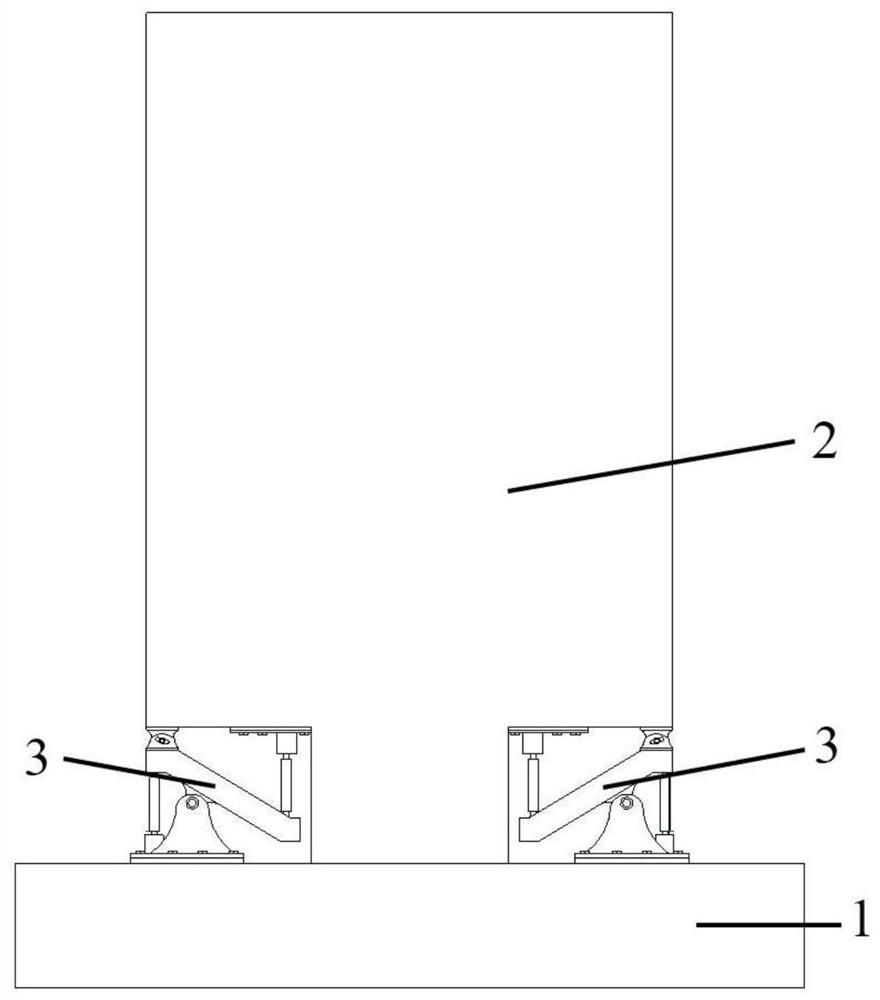

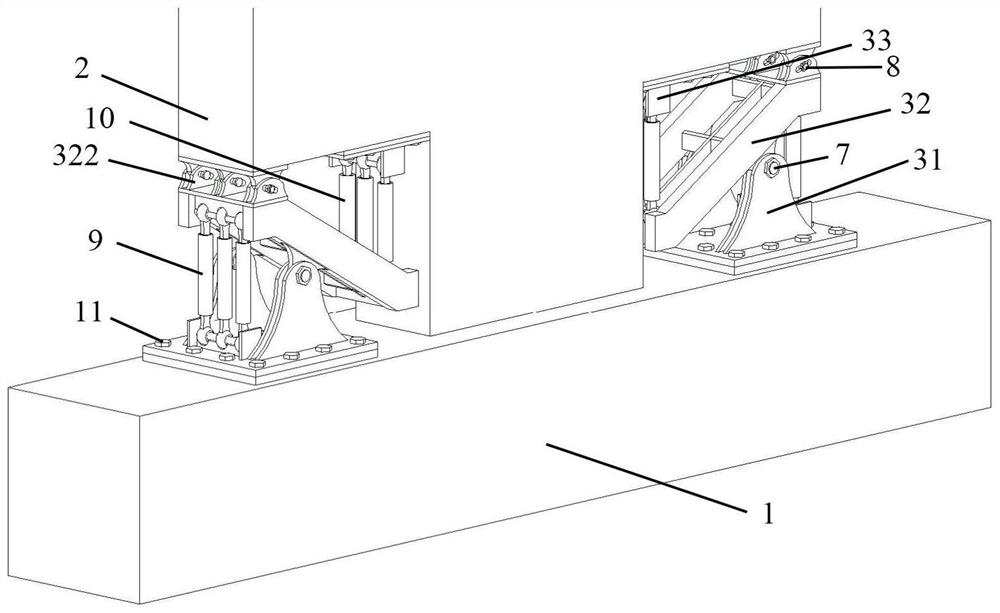

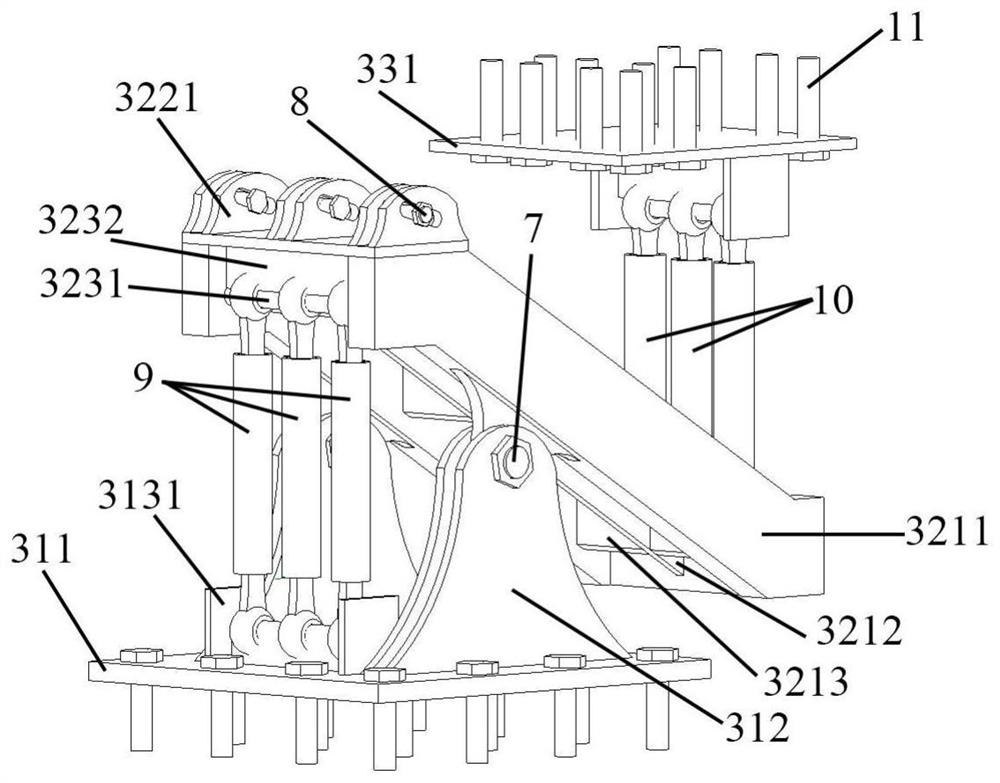

[0039] The shear wall structure of the present invention includes a foundation 1 and a shear wall 2 arranged on the foundation, wherein the shear wall 2 is symmetrically provided with reserved spaces on both sides of the bottom where it is connected to the foundation 1, and in each reserved space A deformation and amplification type energy dissipator 3 is installed. Install the deformed and amplified energy dissipator 3 in the reserved space at the foot of the shear wall 2, connect it with the second embedded part 5 through the pin shaft 7, and connect with the internal thread sleeves of the first embedded part 4 through the high-strength bolts 11 respectively. The connection between the barrel 42 and the internally threaded sleeve 62 of the third embedded part 6 is not only convenient for assembly, but also beneficial for quick replacement of the entire energy dissipator aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com