Vertical connection structure for prefabricated hollow shear wall

A shear wall and prefabricated technology, which is applied to building structures, walls, building components, etc., can solve problems such as unsuitable quality assurance of grout-anchor lap joint holes, high requirements for alignment accuracy of components, and difficulties in quality inspection. Achieve the effects of simple and clear force on the interface, simple and clear calculation, and simple and clear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

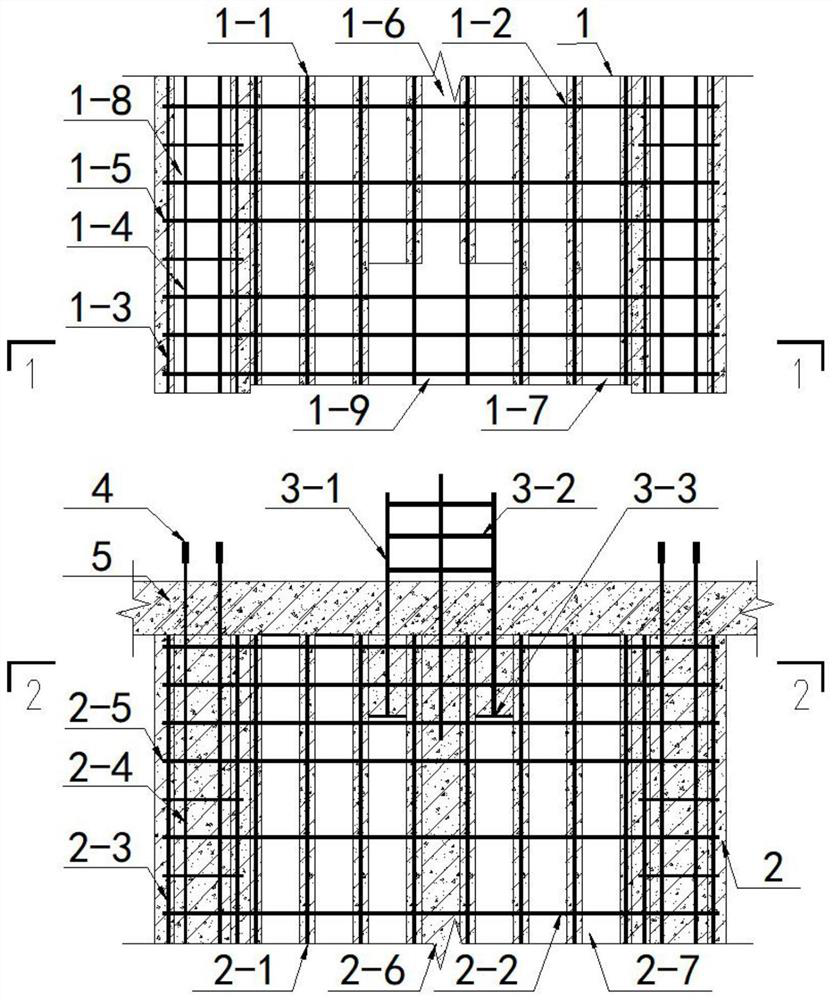

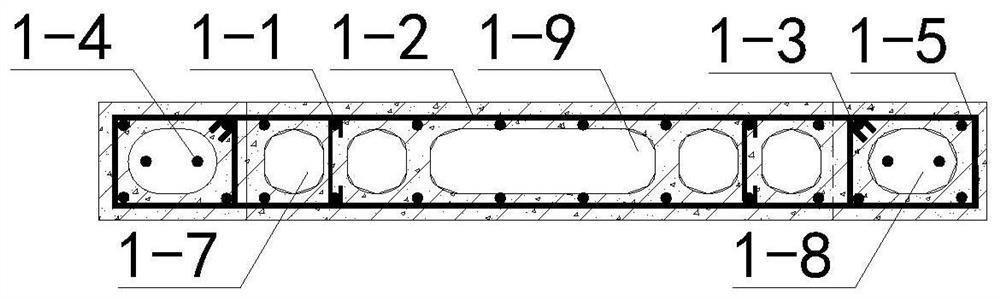

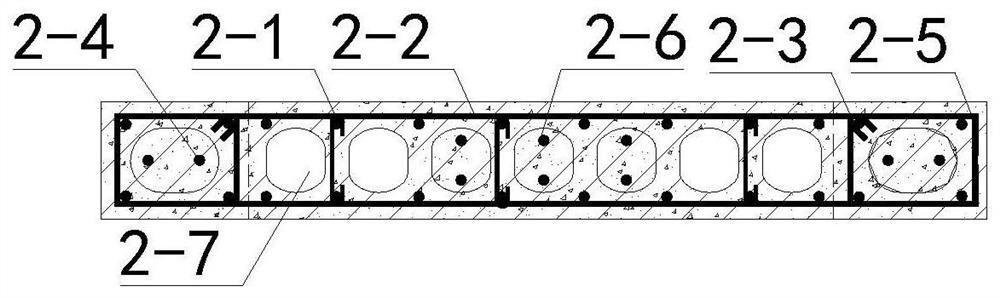

[0028] see Figure 1 to Figure 7 , a vertical connection structure of a prefabricated hollow shear wall, comprising a prefabricated hollow wall 1 with concealed columns on the upper floor, a prefabricated hollow wall 2 with concealed columns on the lower floor, and an intermediate floor 5, which are relatively connected up and down. The prefabricated hollow wall with hidden columns is prefabricated together with the upper and lower hidden columns, and a series of holes are opened inside the wall along the wall height direction; Concealed columns with holes at both ends of the body are connected with the cast-in-place inner alveoles in the middle; the concealed columns with holes are holes of a certain size along the direction of the column he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com