Probe card for high-temperature and high-pressure testing of power device and key structure thereof

A high-temperature, high-pressure, power device technology, applied in the field of semiconductor device testing, can solve the problems of reducing the test effect and efficiency, not finding the probe card, and the warping deformation of the probe card, so as to improve the test effect and efficiency and suppress the abnormality Discharge phenomenon, the effect of avoiding abnormal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0038] The following is a specific embodiment of a probe card for high temperature and high voltage testing of power devices.

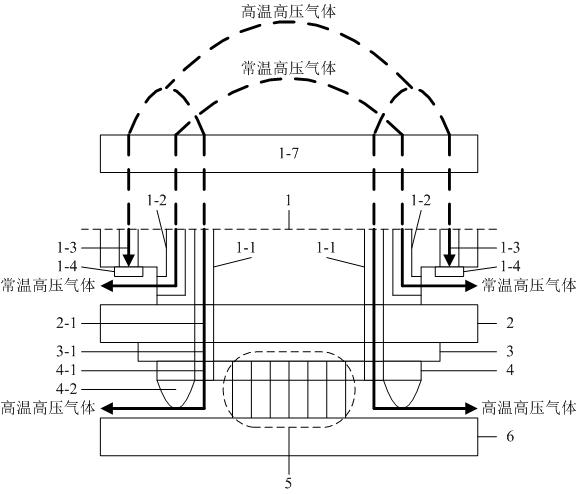

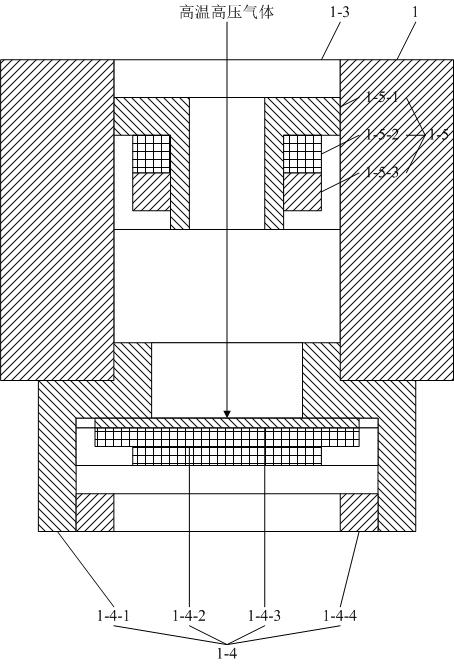

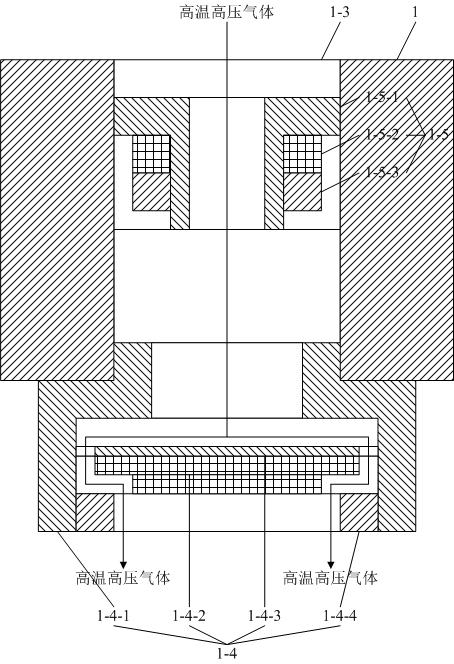

[0039] The power device high temperature and high pressure test probe card of this embodiment, such as figure 1 As shown, the probe card is sequentially provided with an air intake system 1, a PCB board 2, an adapter layer 3, a guide plate 4, and a probe 5 from top to bottom; the bottom of the air intake system 1 has a plurality of lower air outlet holes 1 -1 and side air outlet 1-2, the PCB board 2 is distributed with the first through hole 2-1 having the same position, shape and quantity as the lower air outlet 1-1, and the transfer layer 3 is distributed with The second through hole 3-1 with the same position, shape and quantity as the lower air outlet hole 1-1, and the third through hole with the same position, shape and number as the lower air outlet hole 1-1 is distributed on the guide plate 4 The hole 4-1, the lower air outlet 1-1, the first t...

specific Embodiment 2

[0050] The following is a specific embodiment of a probe card for high temperature and high voltage testing of power devices.

[0051] In the above-mentioned probe card for high temperature and high pressure testing of power devices, the cross-sectional area of the side air outlet 1-2 gradually increases according to the flow direction of the constant temperature air, and the shape of the outer end of the side air outlet 1-2 is as wide as Rectangular larger than the height; below the outer end of the side air outlet 1-2, the rotating shaft is connected with a baffle 1-2-1, and the other side edge of the baffle 1-2-1 is equipped with a pull cord 1-2 -2, the pull rope 1-2-2 passes through above the side air outlet hole 1-2, above the side air outlet hole 1-2, a pull rope fixed end 1-2-3 is also provided, and the pull rope Rope fixed end 1-2-3 comprises frame 1-2-3-1, is arranged in frame 1-2-3-1 and can move up and down along frame 1-2-3-1 fixed plate 1-2-3 -2, Compression sp...

specific Embodiment 3

[0054] The following is a specific embodiment of a probe card for high temperature and high voltage testing of power devices.

[0055] The probe card for high-temperature and high-pressure testing of power devices in this embodiment further defines that the air intake system 1 further includes a double inlet device 1-7 on the basis of the specific embodiment 1, and the double inlet device 1 -7 According to the direction of air flow, it includes air pump 1-7-1, the first three-way valve 1-7-2, and the high-temperature and high-pressure box 1-7-3 connected to the first outlet of the first three-way valve 1-7-2 , connected to the normal temperature and high pressure box 1-7-4 of the second outlet of the first three-way valve 1-7-2, the high temperature and high pressure box 1-7-3 is provided with a resistance wire 1-7-3-1, a temperature sensor 1-7-3-2 and the first pressure gauge 1-7-3-3, the second pressure gauge 1-7-4-1 is set in the normal temperature and high pressure box 1-7...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap