Multistage redundancy mutual inspection motor controller and control method

A technology of motor controller and control method, which is applied in the direction of motor control, motor speed or torque control, computer control, etc., and can solve the problem that the controller cannot control multiple motors together, without further comparison and setting, and motor control To avoid issues such as reduced reliability of the device, to prevent direct connection, ensure information retention, and increase reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

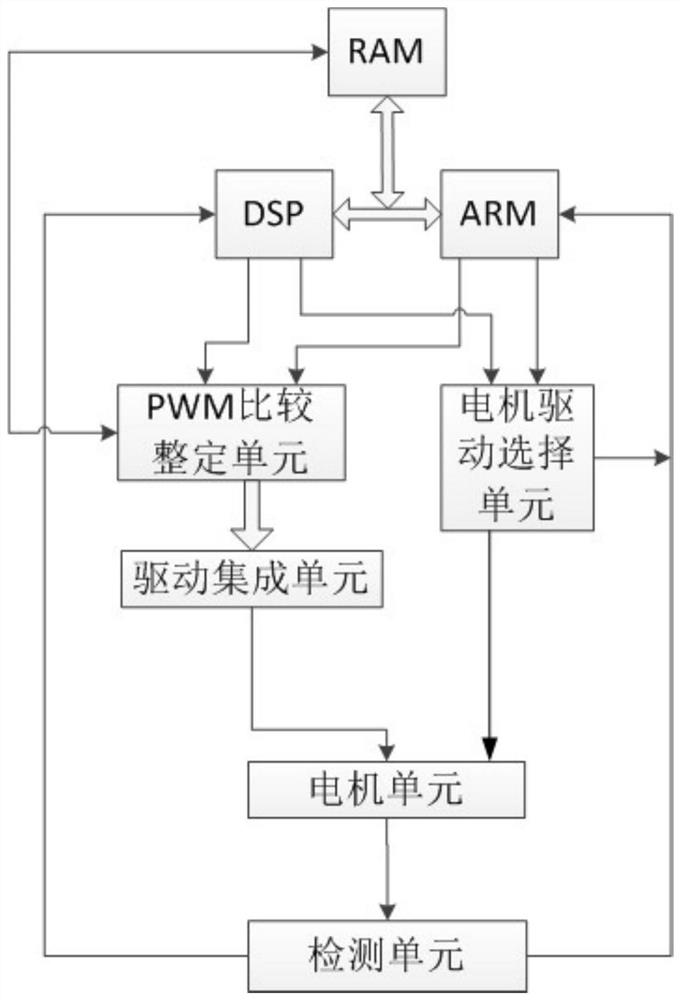

[0064] Such as figure 1 As shown in the schematic diagram of the motor controller, it includes a RAM, a DSP controller, an ARM controller, a PWM comparison and setting unit, a motor drive selection unit, a drive integration unit, a motor unit and a detection unit.

[0065] Such as figure 1 As shown in the schematic diagram of the motor controller, in the motor controller, the RAM is connected to the DSP controller and the ARM controller, and the RAM is connected to the PWM comparison and setting unit; the DSP controller and the ARM controller are connected to form a dual processor. When one control chip or motor breaks down, another control chip can be used as a backup to ensure the reliability of the controller. At the same time, the DSP controller and the ARM controller are connected to the PWM comparison and setting unit, connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com