Full-automatic system of modular full-compatible ophthalmic examination instrument

An ophthalmic examination, fully automatic technology, applied in the field of fully automatic systems, can solve the problems of short fundus filling time, easy fatigue of the operator, ignorance of the shape and size of the lesion location, etc., achieving great social and economic value, reducing operation. Difficulty and work intensity, the effect of promoting automation transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

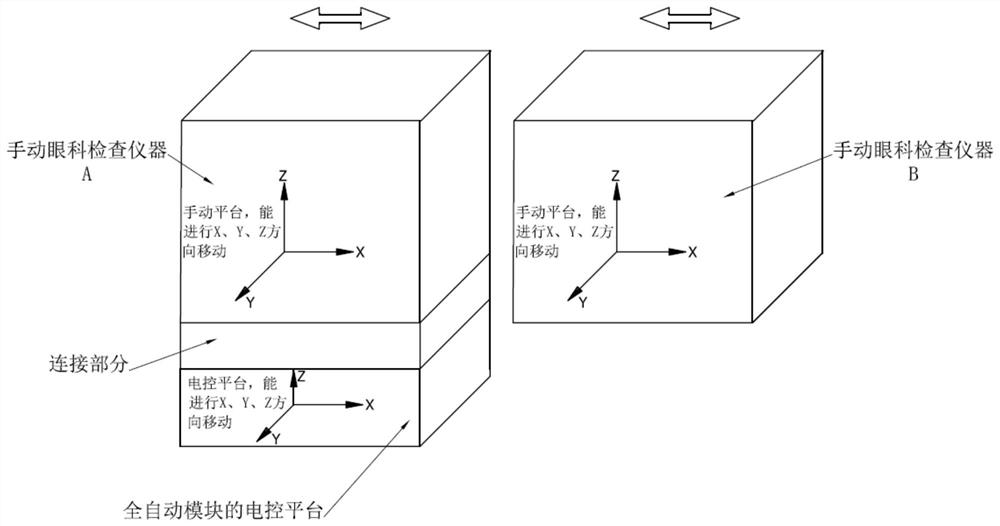

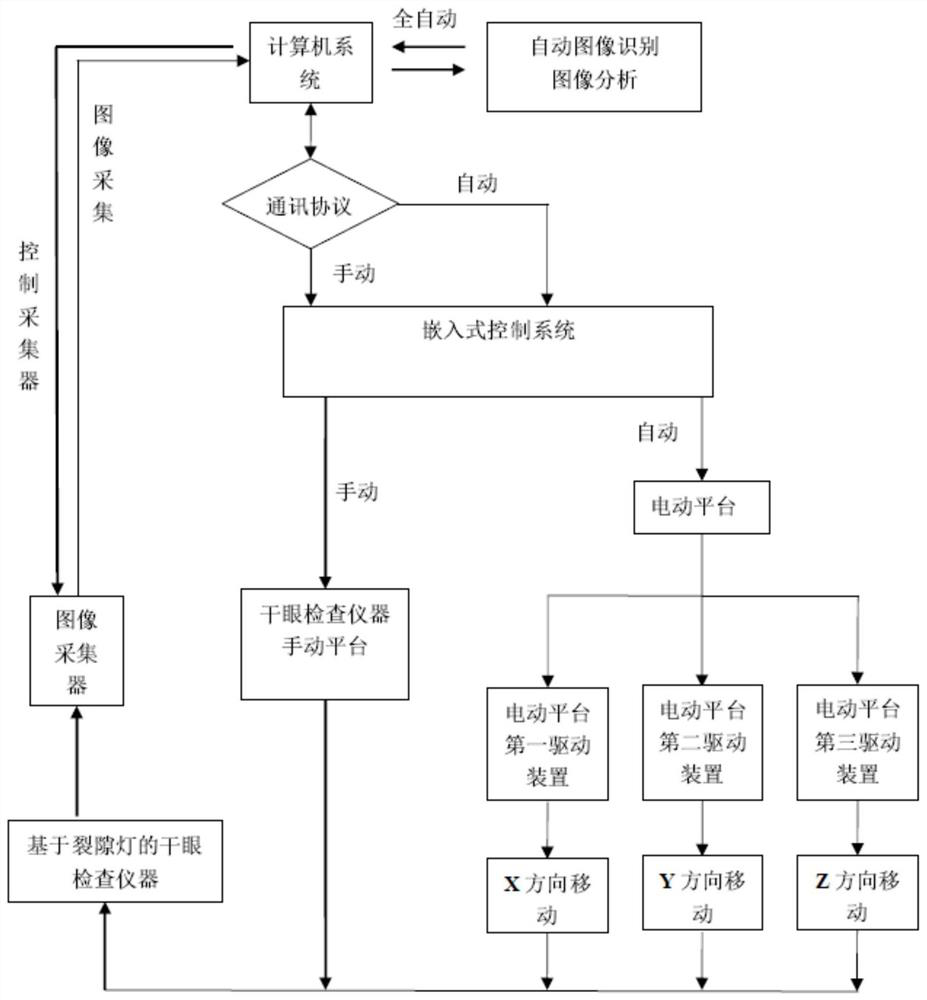

[0093] Embodiment 2 (a multiplexing fully automatic system based on a dry eye inspection instrument based on a slit lamp and a fundus camera instrument and a fully automatic combination) is described in detail, so that the advantages and characteristics of the present invention can be more easily understood by those skilled in the art, Thereby, the protection scope of the present invention is defined more clearly.

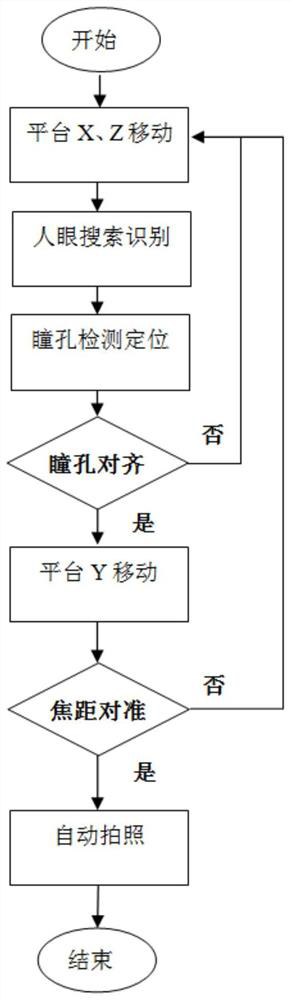

[0094] Such as Figure 11 to Figure 12 Shown: a modular fully compatible multiplexed full-automatic system of dry eye examination instrument based on slit lamp and fundus camera instrument, including automatic module, dry eye examination instrument 7 based on slit lamp (referred to as slit lamp dry eye) and Fundus camera instrument 11 (referred to as fundus camera);

[0095] When the automatic module and the slit lamp dry eye 7 form a dry eye automatic system. The pulley 12 at the bottom of the dry eye 7 of the slit lamp slides along the slide rail 13 to the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com