A chemical waste gas treatment device for olefin separation device

A waste gas treatment device and olefin separation technology, which is applied in separation methods, filtration separation, chemical industry, etc., can solve the problems of equipment shutdown and replacement, affecting work efficiency, difficult tank cleaning, etc., and achieve the effect of convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

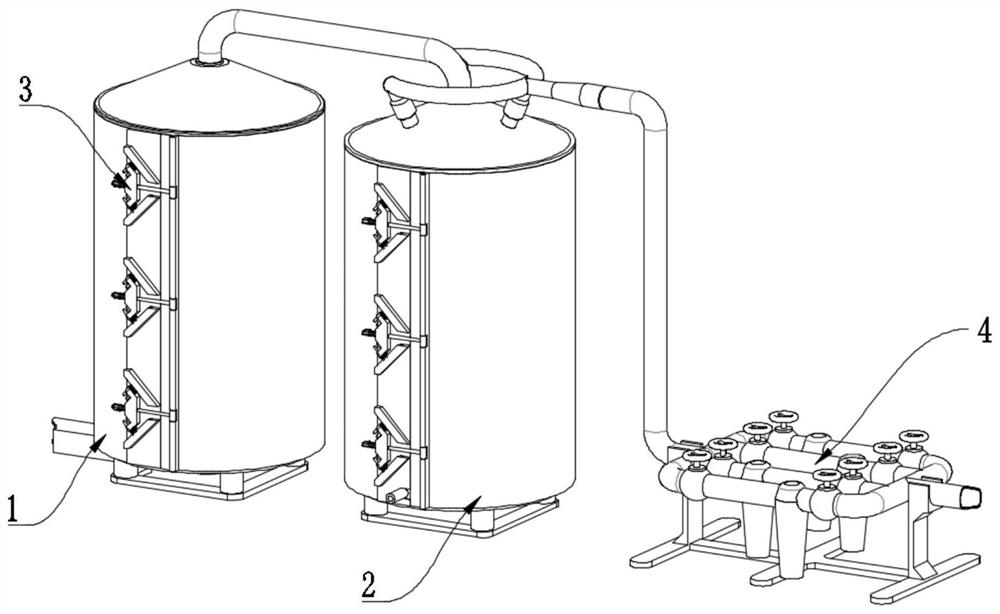

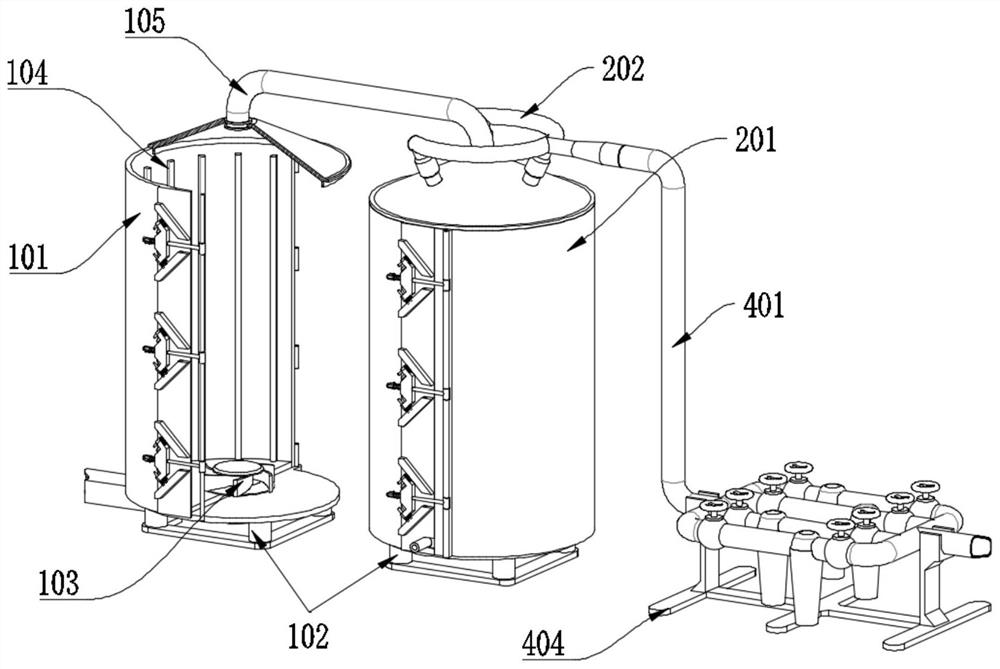

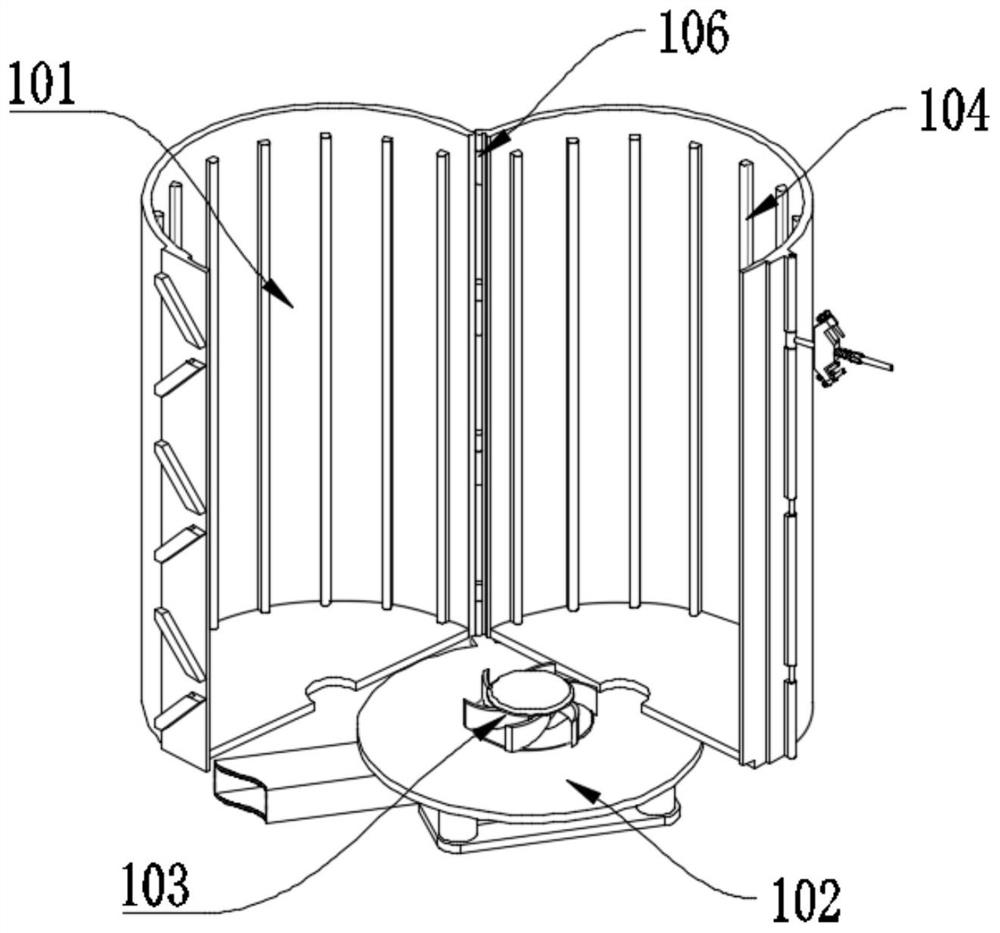

[0034] as attached figure 1 to the attached Figure 8 shown:

[0035] The present invention provides a chemical waste gas treatment device for an olefin separation device, which includes a treatment structure 1; the treatment structure 1 and the purification structure 2 are in an independent state as a whole, and the treatment structure 1 and the purification structure 2 pass through the top of the The pipeline is connected; both the purification structure 2 and the treatment structure 1 are fixed by the clamping structure 3, and the end of the purification structure 2 is provided with a filter structure 4, the bottom groove 203 inside the sealing box 201 is provided with a drain pipe, and the bottom groove 203 The top edge of the sealing box 201 is in a state of being close to the inner wall of the sealing box 201. The top end cover of the sealing box 201 is provided with three joints for the top pipes 202. A drain pipe allows the waste liquid after spraying to flow out, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com