Modular and standardized assembly method and platform of multi-station large automatic production line

An automated production line and automated production line technology, applied in the field of automation, can solve problems such as time consumption, long transmission time, incoherent transmission blocking and positioning, etc., and achieve the effects of improving efficiency, reducing costs, and reducing the difficulty and cost of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

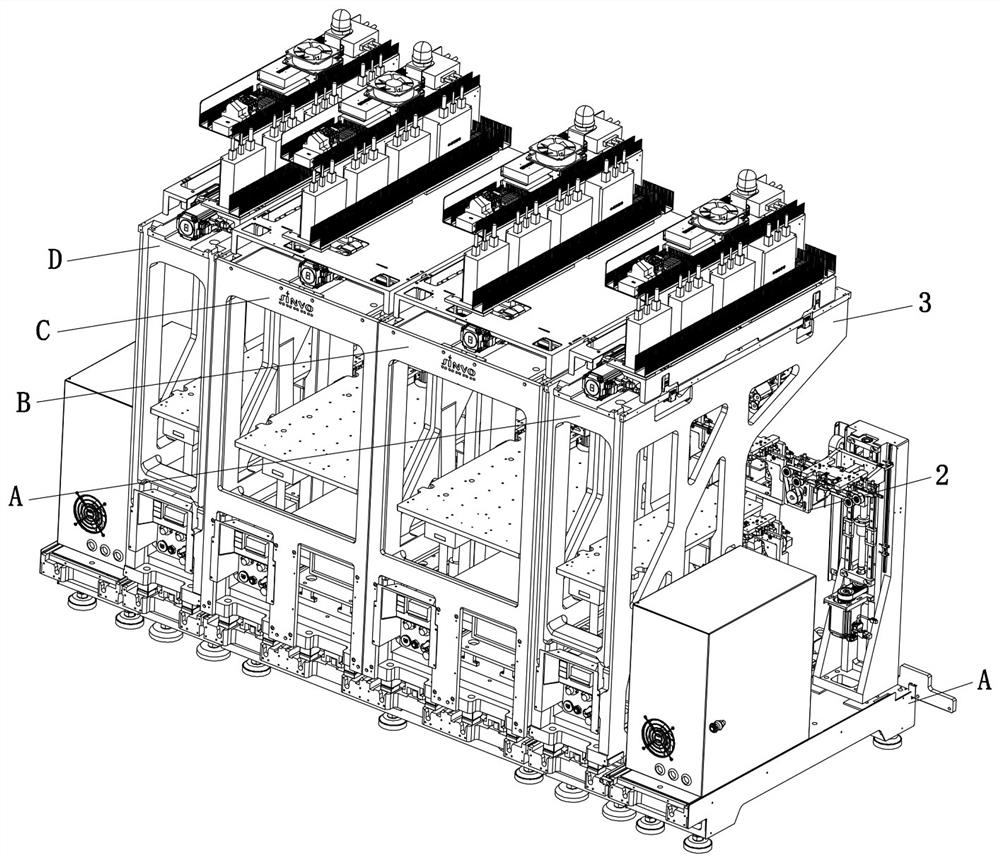

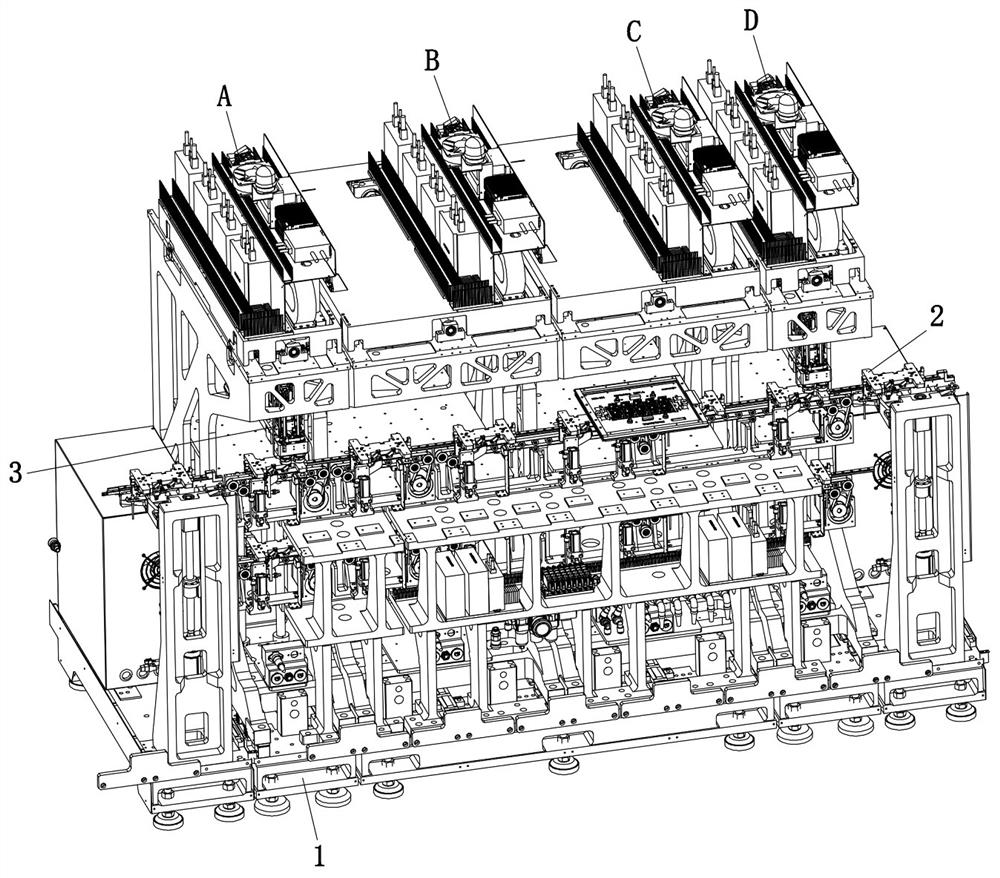

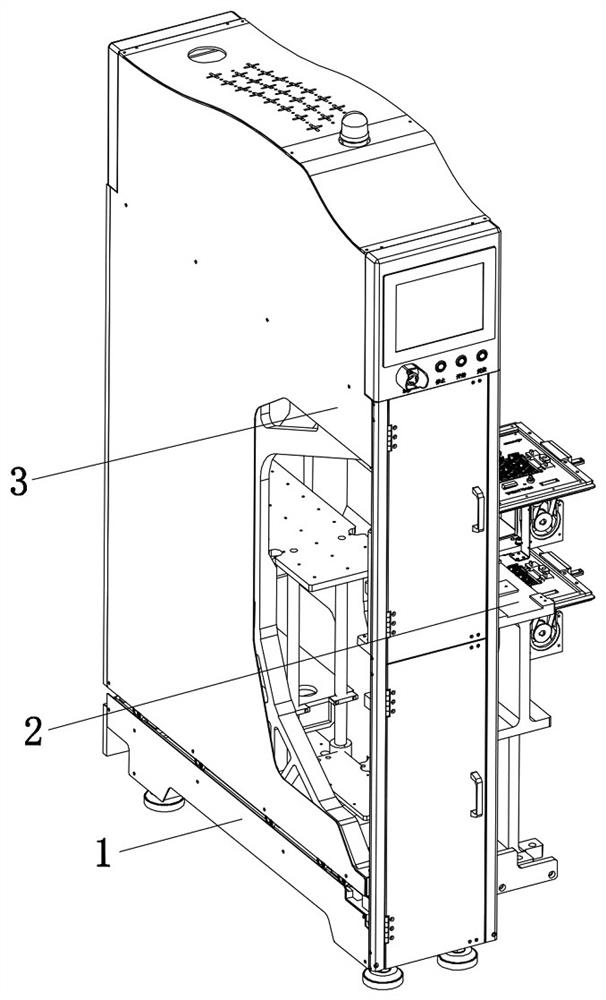

[0063] The present invention will be further described below in conjunction with accompanying drawing:

[0064] Such as Figure 1 to Figure 30 As shown, the technical solution adopted by the present invention is as follows: a modularized and standardized assembly method for a multi-station large-scale automated production line, including a base, a pull body and a functional module, wherein the base and the pull body adopt a standardized structure, and the base and The size library of the pull body includes at least two sizes from large to small; the above-mentioned functional modules and the base are detachably installed; the base, pull body and functional modules are assembled according to standardized assembly processes to form a multi-station large-scale automated production line , the above-mentioned standardized assembly process includes the following process steps:

[0065] S1. Target matching of multi-station large-scale automated production line: perform target matchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com