Vertical-lathe polishing tool and integrated machining method for improving roughness for large-diameter inner hole

A large-diameter and roughness technology, applied in the field of large-diameter inner hole vertical lathe polishing tooling and the integrated processing field of improving roughness, can solve the problems of affecting the production progress, high processing costs, and inability to guarantee the processing cycle, and achieves the use and The effect of convenient disassembly, avoiding cost increase and simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

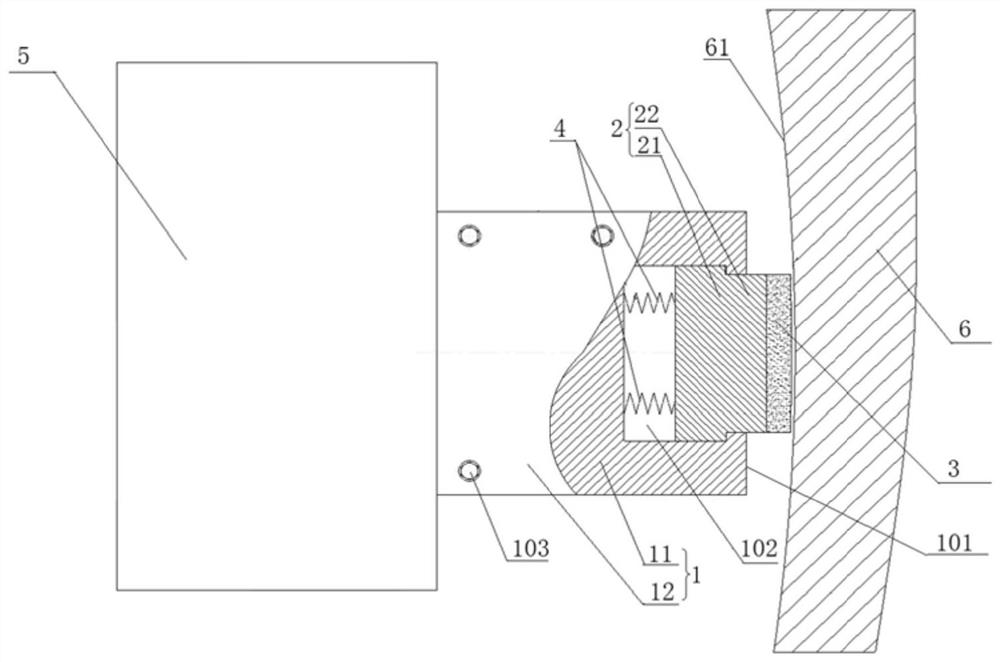

[0034] A large-diameter inner hole vertical lathe polishing tool, such as figure 1 As shown, it is used for polishing the large-diameter inner hole of the workpiece 6, including a main body block 1, a connecting plate 2, a honing strip 3 and an elastic element 4, wherein:

[0035] The main body block 1 is used to be connected to the tool rest 5 of the vertical lathe, and has a working end 101 for pointing to the inner hole side wall 61 of the workpiece 1 fixed on the rotary table of the vertical lathe. The working end 101 of the main body block 1 is provided with Mounting groove 102; the connecting plate 2 is embedded in the mounting groove 102, and has an extension 22 protruding from the opening of the mounting groove 102. The connecting plate 2 can slide relative to the mounting groove 102 on the straight line where the working end 101 points to. The honing strip 3 is arranged at the end of the extension 22 of the connecting plate 2;

[0036] The present invention utilizes ...

Embodiment 2

[0041] An integrated processing method for increasing the roughness of a large-diameter inner hole in this embodiment, using the tooling of Embodiment 1, includes the following steps:

[0042] S1: The workpiece continues to maintain the clamping state of the previous process (usually the previous process refers to the inner hole of the workpiece) on the rotary table of the vertical lathe, and the tooling is installed on the tool holder of the vertical lathe;

[0043] S2: Rotate the workpiece, move the tool holder of the vertical lathe along the radial direction of the workpiece, drive the tooling to move to the side wall of the inner hole of the workpiece, so that the honing strip is close to the side wall of the inner hole of the workpiece under the action of the elastic element;

[0044] S3: The tool holder of the lathe moves in the axial direction of the workpiece, and the side wall of the inner hole is processed by the honing strip to improve the roughness of the inner hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com