Continuous fiber composite material additive manufacturing Z-direction reinforcing method and manufacturing equipment

A composite material and continuous fiber technology, applied in the field of additive manufacturing, can solve the problems of low comprehensive performance of composite materials and unsolved Z-direction reinforcement, and achieve the effect of improving Z-direction strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

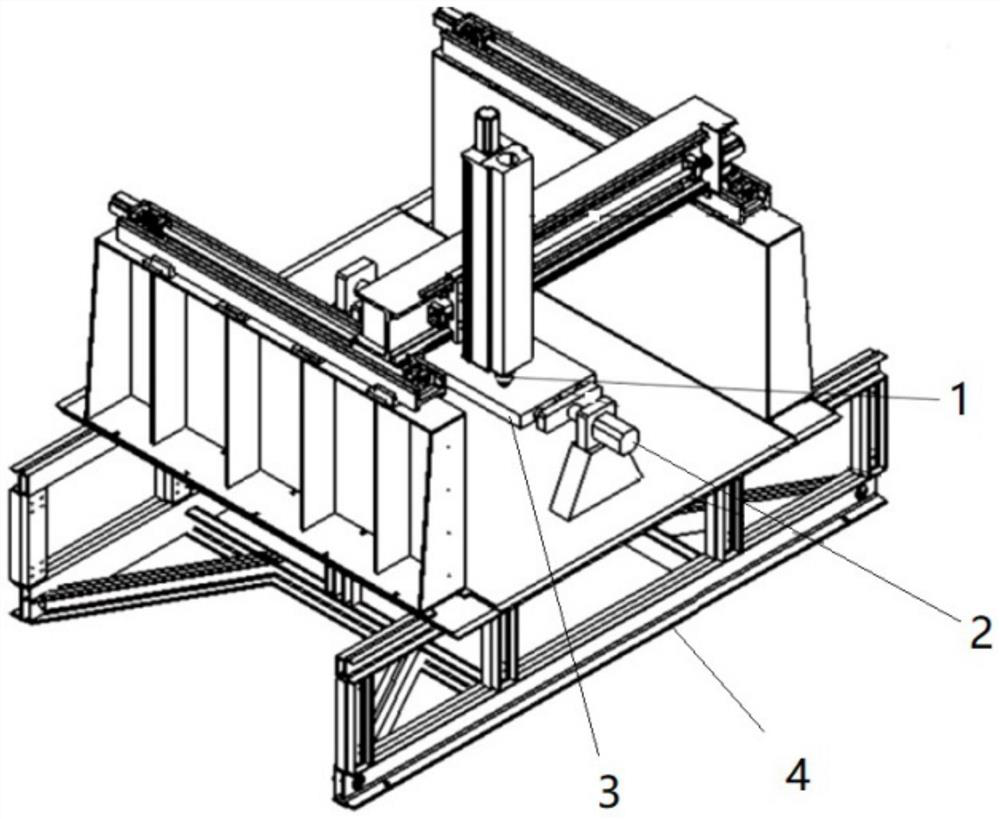

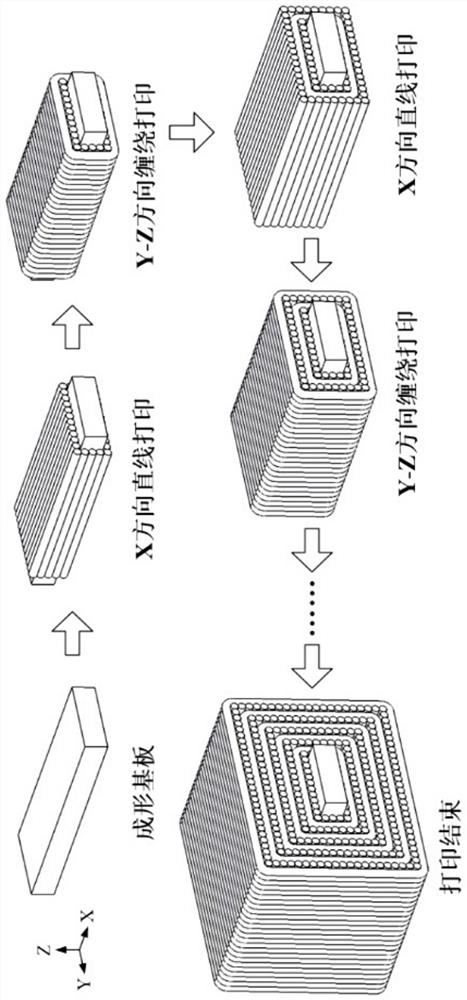

[0023] The Z-direction reinforcement method and manufacturing equipment for additive manufacturing of continuous fiber composite materials provided by the present invention will be further described below in conjunction with specific embodiments.

[0024] A Z-direction reinforcement method for continuous fiber composite material additive manufacturing, comprising the following steps:

[0025] Create 3D models of preformed continuous fiber reinforced composite parts;

[0026] Use layering software to process the 3D model in layers to obtain layer data files;

[0027] The ply data file is converted into a forming path drive signal file that can be directly recognized by the additive manufacturing equipment;

[0028] Printing is performed according to the drive signal file.

[0029] 1. First establish the 3D model of the preformed continuous fiber reinforced composite material, and then use layering software to layer the model to obtain the layer data file, and the layer data f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap