Full-automatic material taking control system of bucket wheel machine

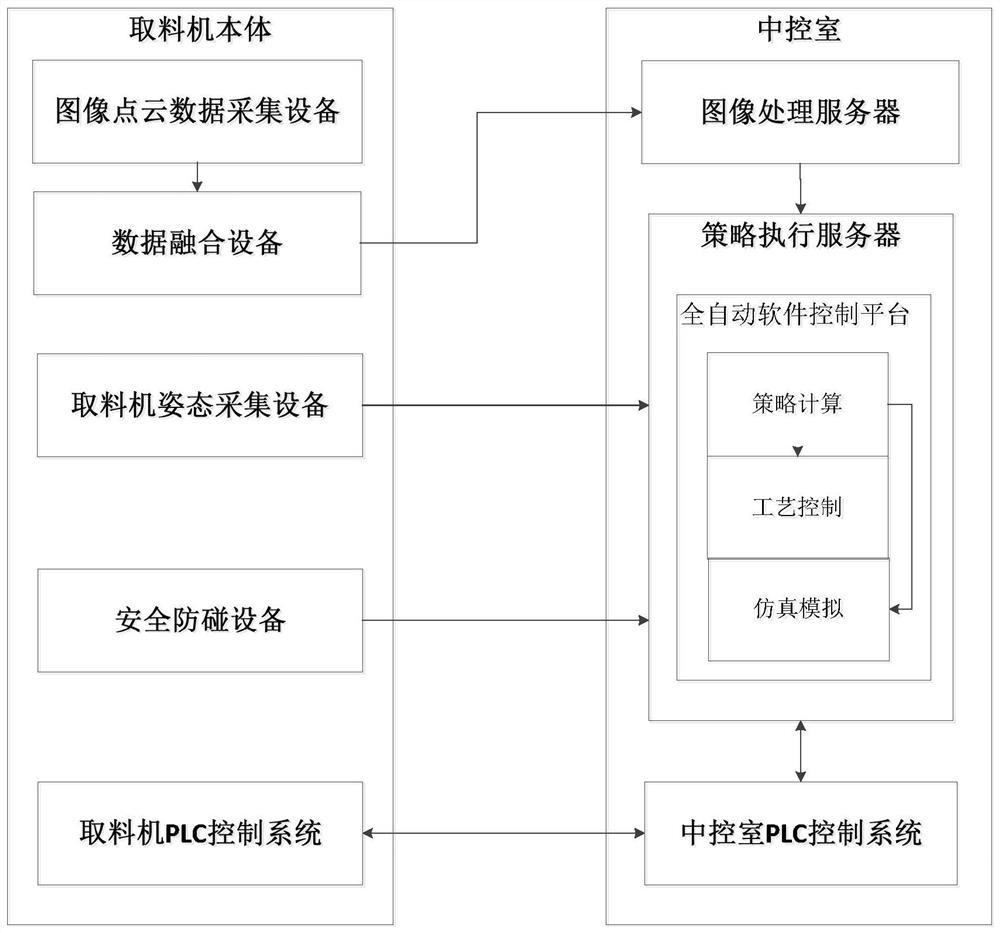

A control system and bucket wheel technology, which are applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as low operation standardization and efficiency, high cost, and harsh labor environment, and achieve standardized and unsatisfactory conditions. The effect of reducing the construction cost and improving the accuracy of data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

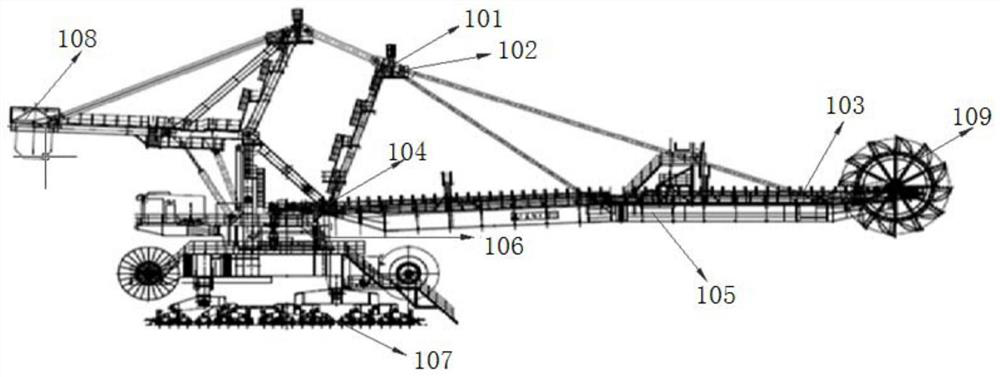

[0057] Figure 2-3As shown, the fully automatic reclaiming control system provided in this embodiment is implemented on the QL6000.55 bucket wheel reclaimer of Huaneng Caofeidian Port Company, which mainly includes a pitching hinge point mechanism, a cantilever mechanism, a rotary platform mechanism, and a walking Mechanism, counterweight mechanism, bucket wheel mechanism and automatic material reclaiming control system; the slewing platform mechanism is set in the middle of the bucket wheel machine and can perform slewing movement in the horizontal direction; the cantilever mechanism is connected to the On the rotary platform mechanism, the end of the cantilever mechanism is provided with a bucket wheel mechanism; the running mechanism is arranged below the rotary platform mechanism; the counterweight mechanism is arranged in the direction opposite to the extension direction of the cantilever mechanism, maintaining Balance of the bucket wheel machine.

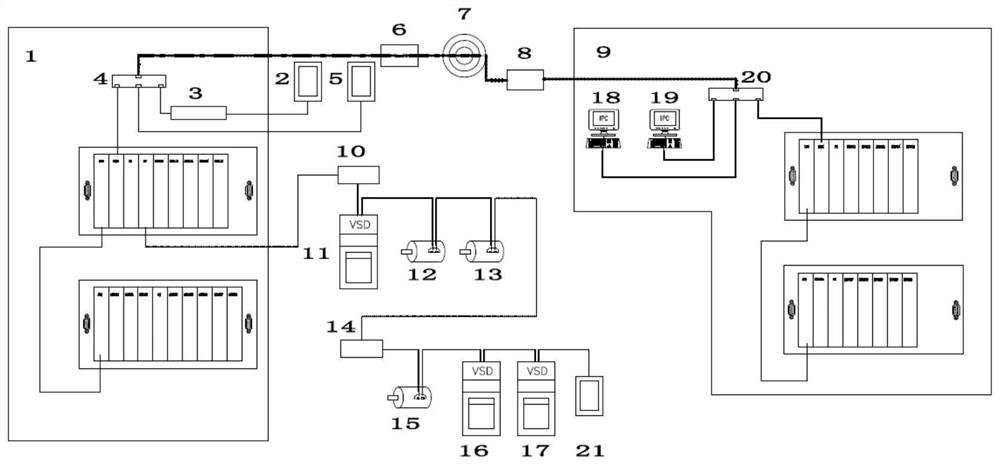

[0058] In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com