Smoke detection method for range hood and range hood

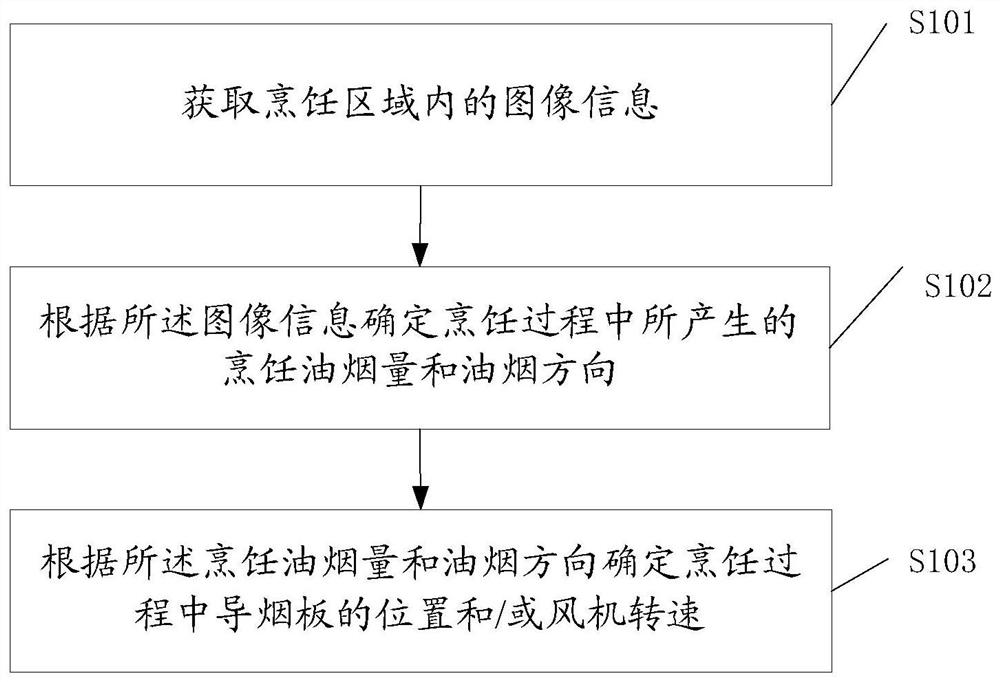

A detection method and the technology of range hoods, which are applied in the direction of oil fume removal, heating methods, lighting and heating equipment, etc., can solve the problems of poor real-time detection, fuzzy control of air volume adjustment, difficulty in adapting to the requirements of large oil fume suction, etc., and achieve fan speed Avoid and ensure real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Such as Figure 7 As shown, this embodiment describes the moving process of the smoke deflector of the range hood.

[0096] The range hood structure design in the embodiment of the present invention includes an image recognition module 100 installed on the hood control panel, and the smoke guide plate can move left and right, wherein the image recognition module 100 includes the hood panel sheet metal bracket 3 and the hood control panel Glass 2, image recognition camera 1 and camera protective glass 4 installed on the sheet metal bracket for protecting the image recognition camera.

[0097] The image recognition module 100 includes a circuit board installation shell, a circuit board substrate, a camera assembly and a communication interface, and the camera is installed facing the cooktop, so that the images of the cooktop table during cooking can be collected in real time in the largest range;

[0098] In the embodiment of the present invention, the image recognition ...

Embodiment 2

[0109] Such as Figure 5 As shown, in this embodiment, the oil fume contact surface of the range hood is divided into three areas, ABC, in advance. During normal cooking, the user will choose any one of the left and right stoves or use both stoves at the same time, and the temperature of the oil fume is higher than that of the surrounding air. High and affected by the suction in the negative pressure area of the range hood, it shows an upward and diffuse trajectory according to a certain rule. Figure 5 Shown is the corresponding relationship between the cooking stove and the oil fume contact surface of the range hood. When there is no obvious air convection (no natural wind blowing in) in the kitchen, the oily fume that diffuses upward mainly comes into contact with areas A and C of the oily fume contact surface and is sucked away by the surrounding air inlets and discharged through the flue; if the user has been here Cooking in this way, the amount of cooking fume generat...

Embodiment 3

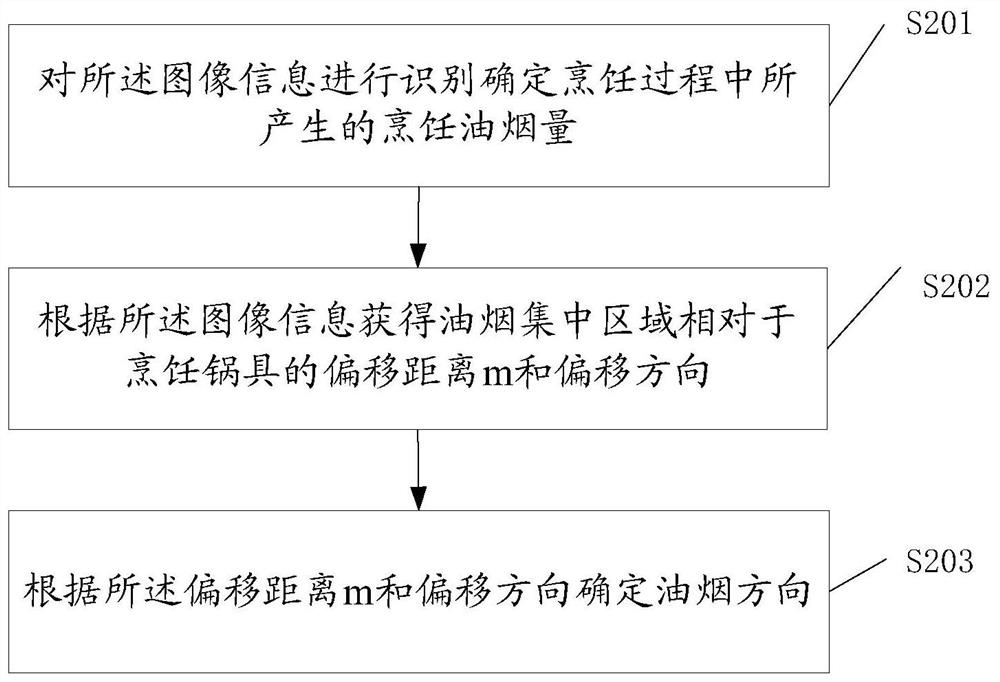

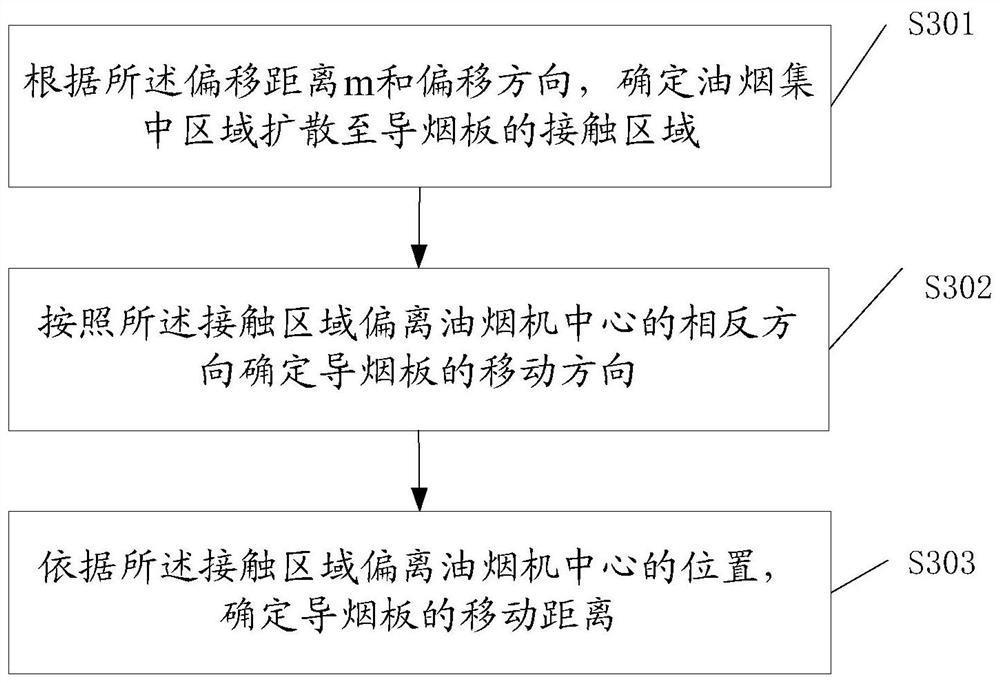

[0123] This example illustrates the determination of the corresponding relationship between the moving distance of the smoke deflector, the speed of the fan, and the concentration area of the oil fume based on the direction of the oil fume:

[0124] When there is oily smoke on the right side of the cooking pot on the left stove or oily smoke on the left side of the cooking pot on the right stove, it can be judged that there is obvious air convection in the kitchen, such as Figure 12 As shown, the oil fume contact surface is divided into three areas, namely A area, B area, and C area. At this time, the oil fume will appear in any of the above three areas, and then consider the installation height of the range hood and the diffusion of oil fume. At this time, the oil fume concentration area does not finally diffuse to the corresponding contact area of the smoke deflector, so it is necessary to obtain the corresponding relationship between the offset distance m of the oil fum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com