Method and system for predicting power grid defect materials through multi-model fusion

A multi-model and defective technology, applied in the field of power grid material information processing, can solve the problems of low material storage efficiency, achieve the effects of reducing costs, enhancing reliability, and improving planning capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

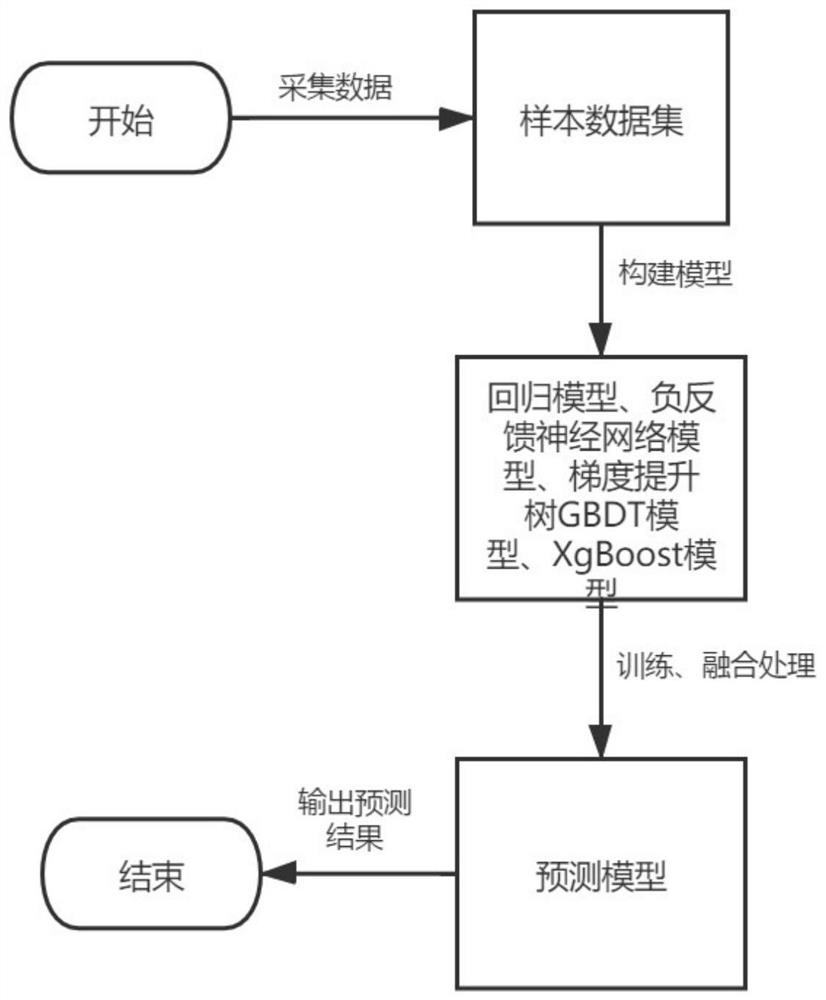

[0039] refer to figure 1 and figure 2 , which is the first embodiment of the present invention, this embodiment provides a method for multi-model fusion to predict power grid defect materials, including:

[0040] S1: Construct regression model, negative feedback neural network model, gradient boosting tree GBDT model and XgBoost model sequentially based on the failure probability strategies of different regions, time and equipment. What needs to be explained is:

[0041] The regression model solves the optimization objective, as follows,

[0042]

[0043] Among them, n samples : number of samples, w: weight coefficient of the vector in each dimension of the sample, X: sample data, y: amount of material defects, α, β: regularization coefficient, ||w|| 1 ,||w|| 2 Respectively, the first-order norm and the second-order norm of the coefficient;

[0044]

[0045] in, The predicted value of defective materials (the unit is a piece, and the value is a positive real num...

Embodiment 2

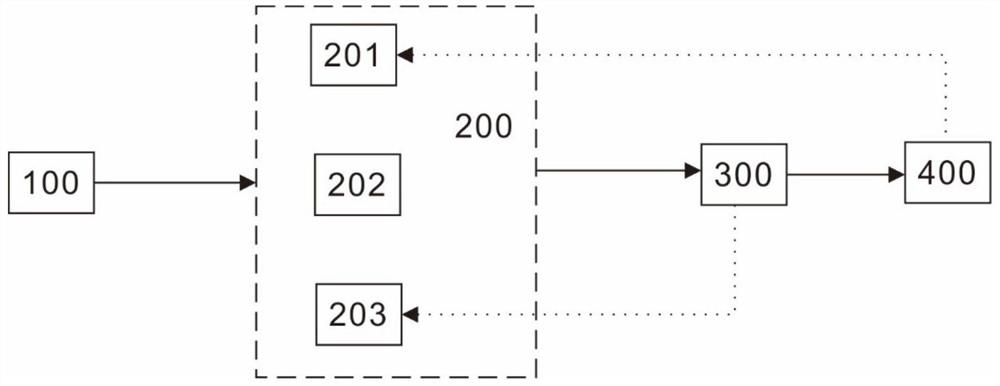

[0091] refer to image 3 , which is the second embodiment of the present invention. This embodiment is different from the first embodiment in that it provides a system for multi-model fusion prediction of power grid defect materials, including:

[0092] The collection module 100 is used for collecting meteorological data and historical defect data and constructing a sample data set.

[0093]The data processing center module 200 is used to receive, calculate, store, and output data information to be processed, which includes a computing unit 201, a database 202, and an input and output management unit 203. The computing unit 201 is connected to the collection module 100 for receiving and collecting The data information obtained by the module 100 is used for calculation and processing, and the prediction results of each model and the fusion prediction results are calculated. The database 202 is connected to each module to store all the data information received, and provides dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com