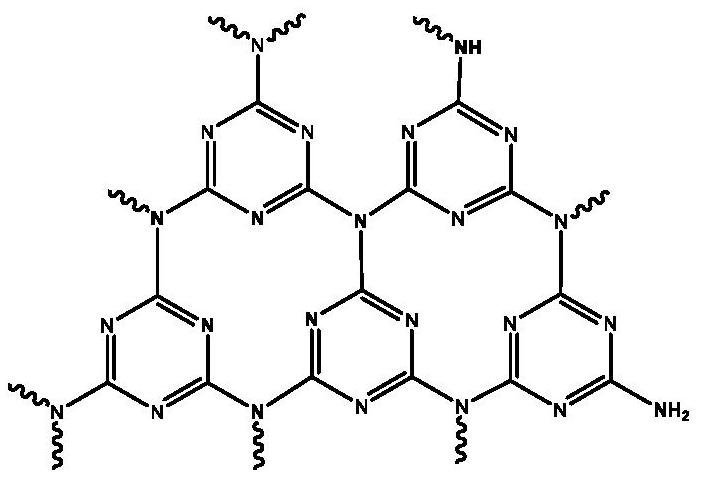

pd/mpg-c 3 no 4 Catalyst recycling method in hbiw hydrogenolysis reaction

A mpg-c3n4, hydrogenolysis reaction technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as catalyst deactivation and achieve the realization of recycling application, reduce production costs, and improve the effect of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

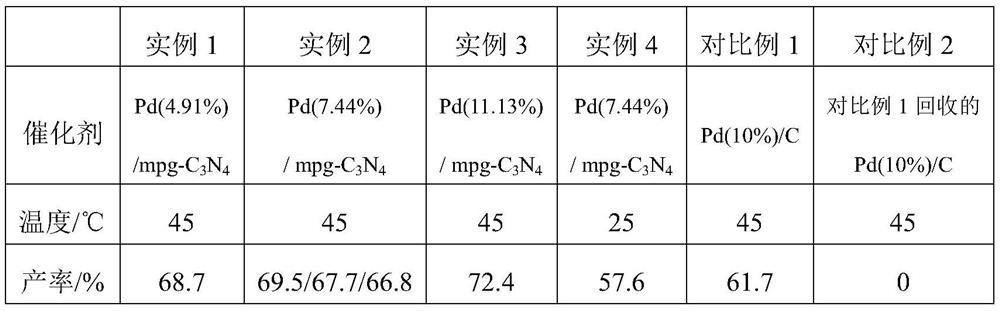

Embodiment 1

[0029] Pd / mpg-C 3 N 4 Catalyst preparation

[0030] 1g mpg-C 3 N 4 Disperse in 100ml deionized water, stir for 15min, add 3.4ml PdCl 2 Aqueous solution (50mg / ml), stirred for 3h, then added 4.2ml NaBH 4 solution (2mg / ml), stirred for 1h, filtered, washed with water until neutral, and vacuum dried at 70°C for 10h to obtain Pd / mpg-C with a palladium content of 4.91%. 3 N 4 catalyst.

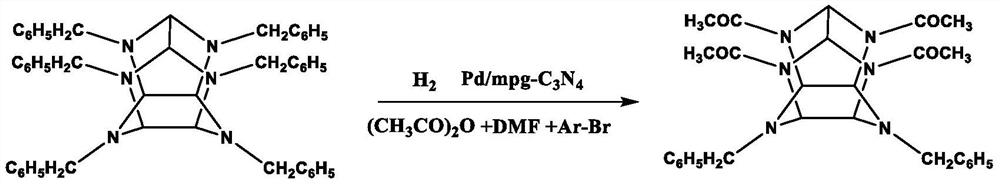

[0031] Hydrogenolysis of Hexabenzylhexaazaisowurtzitane

[0032] 3.4g HBIW, 346mg 4.91% Pd / mpg-C 3 N 4 Add the catalyst and 6ml DMF into the reaction flask, keep the temperature <10°C in a cold water bath, replace the gas in the reaction flask with nitrogen three times, then replace the gas in the reaction flask with hydrogen three times, add 0.06ml of bromobenzene and 6ml of acetic anhydride, and start the stirring reaction. Hydrogen is supplied continuously with a hydrogen balloon. Raise the temperature to 18°C for 1 hour, and then raise the temperature to 45°C for 8 hours. After the...

Embodiment 2

[0034] 1g mpg-C 3 N 4 Disperse in 100ml deionized water, stir for 15min, add 5ml PdCl 2 Aqueous solution (50mg / ml), stirred for 3h, then added 6.2ml NaBH 4 solution (2mg / ml), stirred for 1h, filtered, washed with water until neutral, and vacuum dried at 70°C for 10h to obtain Pd / mpg-C with a palladium content of 7.44%. 3 N 4 catalyst.

[0035] Hydrogenolysis of Hexabenzylhexaazaisowurtzitane

[0036] 3.4g HBIW, 228mg 7.44% Pd / mpg-C 3 N 4 Add the catalyst and 6ml DMF into the reaction flask, keep the temperature <10°C in a cold water bath, replace the gas in the reaction flask with nitrogen three times, then replace the gas in the reaction flask with hydrogen three times, add 0.06ml of bromobenzene and 6ml of acetic anhydride, and start the stirring reaction. Hydrogen is supplied continuously with a hydrogen balloon. Raise the temperature to 18°C for 1 hour, and then raise the temperature to 45°C for 8 hours. After the reaction, cool down to room temperature, filter, ...

Embodiment 3

[0038] 1g mpg-C 3 N 4 Disperse in 100ml deionized water, stir for 15min, add 6.7ml PdCl 2 Aqueous solution (50mg / ml), stirred for 3h, then added 8.3ml NaBH 4 solution (2mg / ml), stirred for 1h, filtered, washed with water until neutral, and vacuum dried at 70°C for 10h to obtain Pd / mpg-C with a palladium content of 11.13%. 3 N 4 catalyst.

[0039] Hydrogenolysis of Hexabenzylhexaazaisowurtzitane

[0040] 3.4g HBIW, 153mg 11.13% Pd / mpg-C 3 N 4 Add the catalyst and 6ml DMF into the reaction flask, keep the temperature <10°C in a cold water bath, replace the gas in the reaction flask with nitrogen three times, then replace the gas in the reaction flask with hydrogen three times, add 0.06ml of bromobenzene and 6ml of acetic anhydride, and start the stirring reaction. Continuous supply of hydrogen with a hydrogen balloon,. Raise the temperature to 18°C for 1 hour, and then raise the temperature to 45°C for 8 hours. After the reaction, cool down to room temperature, filter, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com