Hub color over-coating method, and manufacture method for hub

A manufacturing method and technology for wheel hubs, which are applied to the device, coating, special surface and other directions of coating liquid on the surface, can solve the problems of blurred color registration line and high spraying cost, achieve rich color registration, improve production cycle, and shorten production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

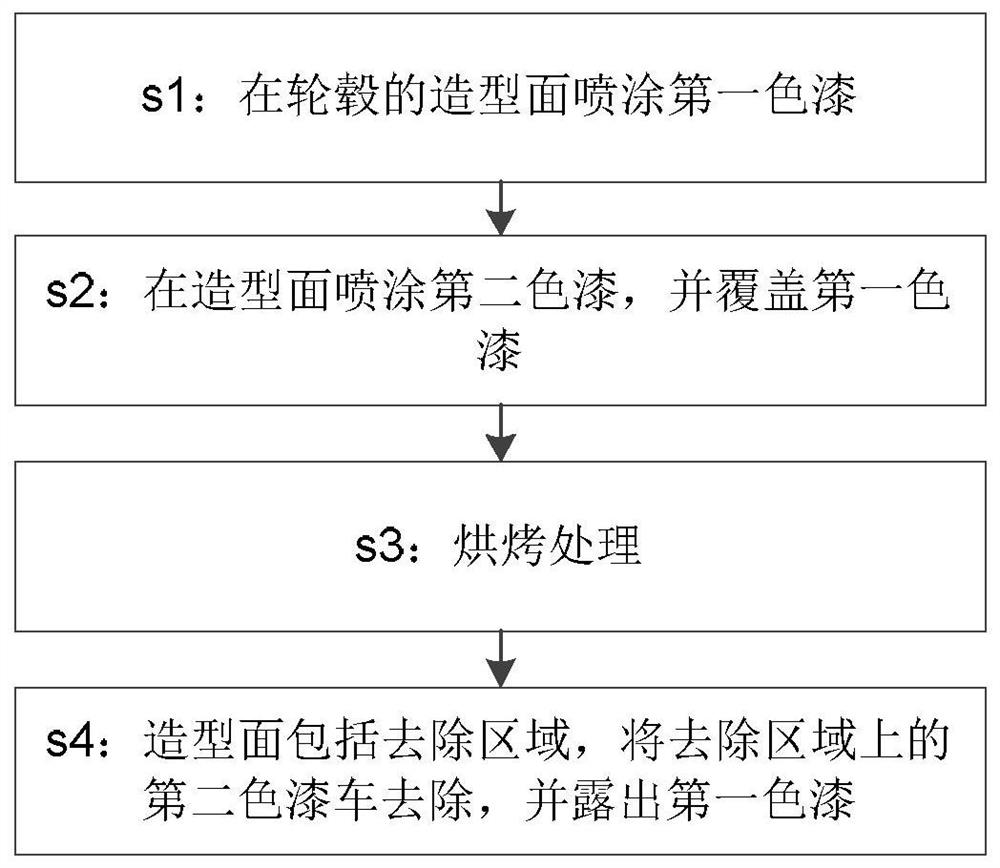

[0041] The invention provides a wheel hub color registration method, such as figure 1 shown, including the following steps:

[0042] s1: Spray the first color paint on the shape surface of the wheel hub;

[0043] s2: Spray the second color paint on the modeling surface and cover the first color paint;

[0044] s3: baking treatment;

[0045] s4: The modeling surface includes the removal area, remove the second color paint on the removal area, and expose the first color paint.

[0046] Specifically, when spraying, the color to be retained in the removed area is first defined as the first color paint, and then the entire modeling surface is fully covered with the first color paint. It should be understood that the modeling surface does not necessarily refer to a plane, but broadly refers to all areas that can be displayed for displaying the shape of the wheel hub, such as areas such as hub spokes and window surfaces. Then define the color to be retained outside the removed ar...

Embodiment 2

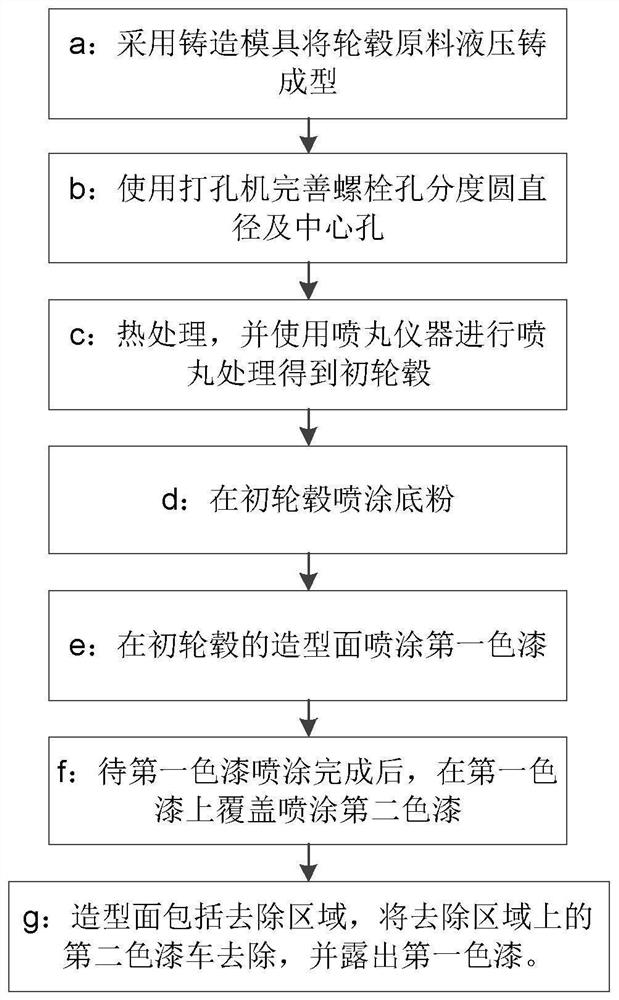

[0065] A method of manufacturing a hub, such as figure 2 shown, including the following steps:

[0066] a: Using a casting mold to hydraulically cast the wheel hub raw material;

[0067] b: Use a punching machine to perfect the center hole of the bolt hole indexing circle diameter;

[0068] c: heat treatment, and use shot peening equipment to perform shot peening treatment to obtain the primary hub;

[0069] d: Spray primer on the primary hub;

[0070] e: Spray the first color paint on the modeling surface of the primary hub;

[0071] f: After the first color paint is sprayed, cover and spray the second color paint on the first color paint;

[0072] g: The modeling surface includes the surface that can be finished, and the finishing treatment is carried out on the surface that can be finished, and the feed rate of the turning tool is adjusted according to the film thickness of the second color paint to remove the second color paint on the surface that can be finished , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com