High temperature titanium alloy plate as well as preparation method and application thereof

A high-temperature titanium alloy and titanium alloy technology, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems that the creep performance of the blade has little effect, the alloy has low potential for high-temperature performance, and is difficult to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a high-temperature titanium alloy plate, comprising the following steps:

[0026] (1) performing the first heat treatment and the first rolling on the titanium alloy slab in turn to obtain the first semi-finished slab; the first rolling is unidirectional rolling;

[0027] (2) cutting the first semi-finished slab described in step (1) to obtain a second semi-finished slab;

[0028] (3) performing the second heat treatment and the second rolling on the second semi-finished slab described in step (2) successively to obtain the third semi-finished slab; the second rolling is unidirectional rolling;

[0029] (4) Heat-treating the third semi-finished slab described in step (3) to obtain a high-temperature titanium alloy plate.

[0030] In the invention, the titanium alloy slab is subjected to the first heat treatment and the first rolling in order to obtain the first semi-finished slab. In the present invention, the titanium all...

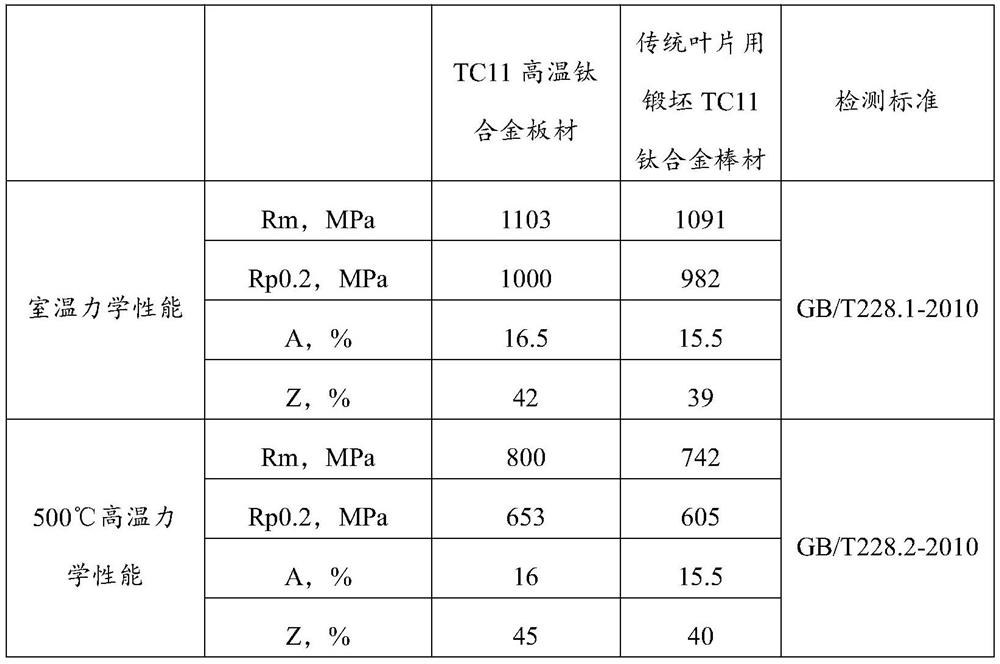

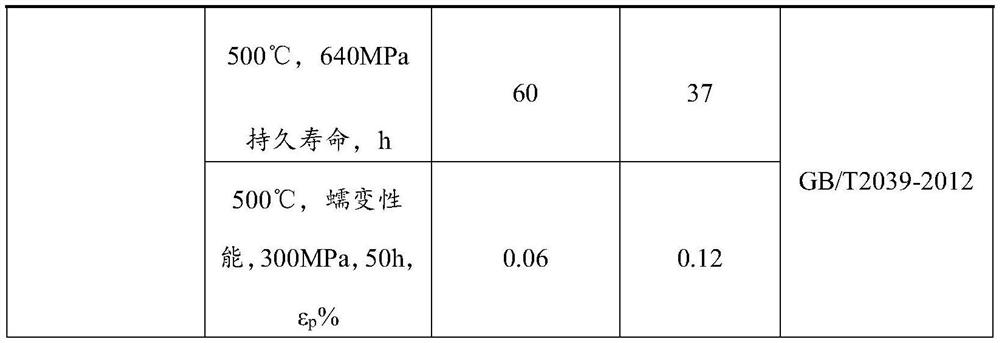

Embodiment 1

[0043] (1) The forged 240mm×1000mm×1200mm, TC11 titanium alloy slab (phase transition point is 1000°C) is subjected to the first heat treatment at 990°C, kept for 210min, and then sent to the hot rolling mill for the first rolling , to obtain the first semi-finished slab of 80mm * 1000mm * 3600mm, the first rolling is unidirectional rolling; the total deformation of the first rolling is 67%;

[0044] (2) grinding and pickling the first semi-finished slab obtained in step (1) successively, and then cutting along the length direction to obtain a second semi-finished slab of 80mm×1000mm×1200mm;

[0045] (3) The second semi-finished slab obtained in step (2) is subjected to a second heat treatment at 990° C., kept for 100 minutes, and then sent to a hot rolling mill for a second rolling to obtain a plate with a size of 40 mm × 1000 mm × 2400 mm , after the rolling is completed, the plate is quickly transported back to the heating furnace, and the heat treatment is carried out at 9...

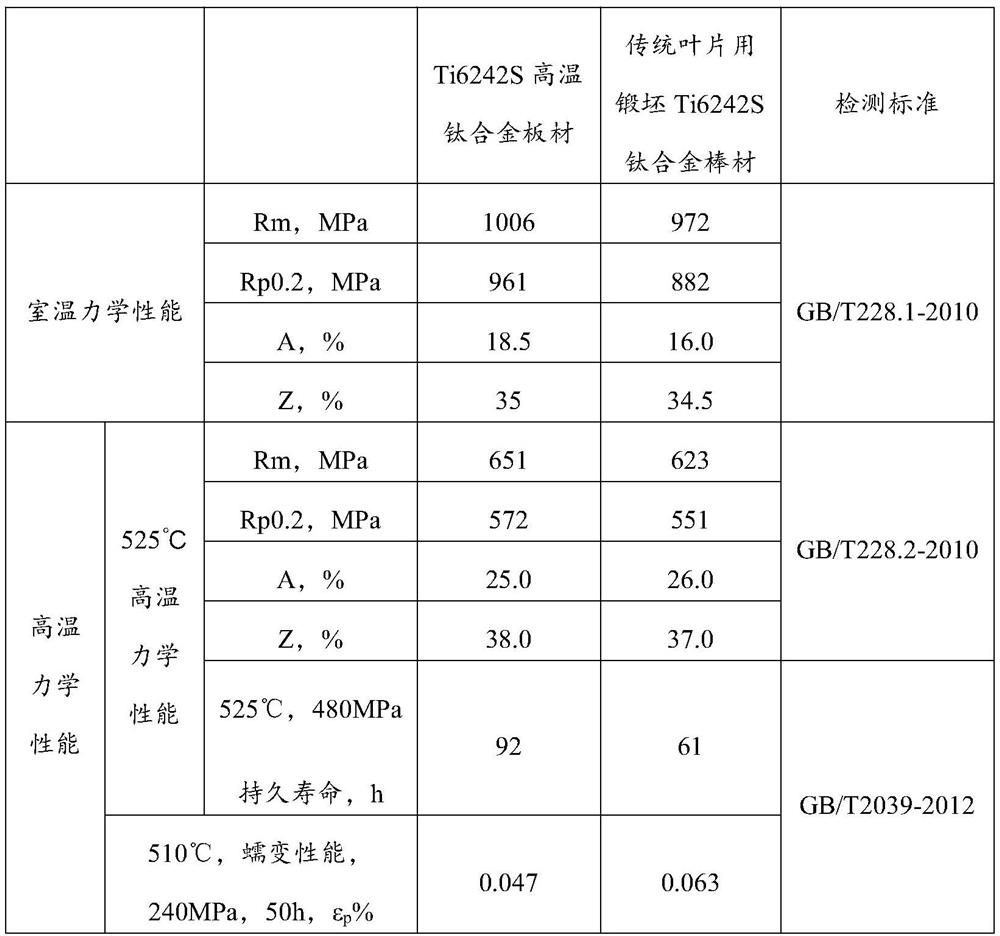

Embodiment 2

[0053] (1) The forged 120mm×800mm×1050mm, Ti6242S titanium alloy slab (phase transition point is 1015°C) is subjected to the first heat treatment at 995°C, kept for 150min, and then sent to the hot rolling mill for the first rolling , to obtain the first semi-finished slab of 48mm * 800mm * 2625mm, the first rolling is unidirectional rolling; the total deformation of the first rolling is 60%;

[0054] (2) grinding and pickling the first semi-finished slab obtained in step (1) successively, and then cutting to obtain a second semi-finished slab of 48mm × 800mm × 1310mm;

[0055] (3) The second semi-finished slab obtained in step (2) is subjected to a second heat treatment at 995° C., kept for 68 minutes, and then sent to a hot rolling mill for a second rolling to obtain a slab with a size of 19.2 mm × 800 mm × 3275 mm. After the rolling, the plate is quickly transported back to the heating furnace, heat-treated at 995°C for 29 minutes, and then quickly transported to the rapid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com