Container storage system, warehousing system, robot control method and robot

A storage system and storage system technology, applied in the fields of robots, computing equipment, computer-readable storage media, and container storage systems, can solve problems such as low storage density of material boxes, reduce energy consumption, save picking costs, and reduce elongation. effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

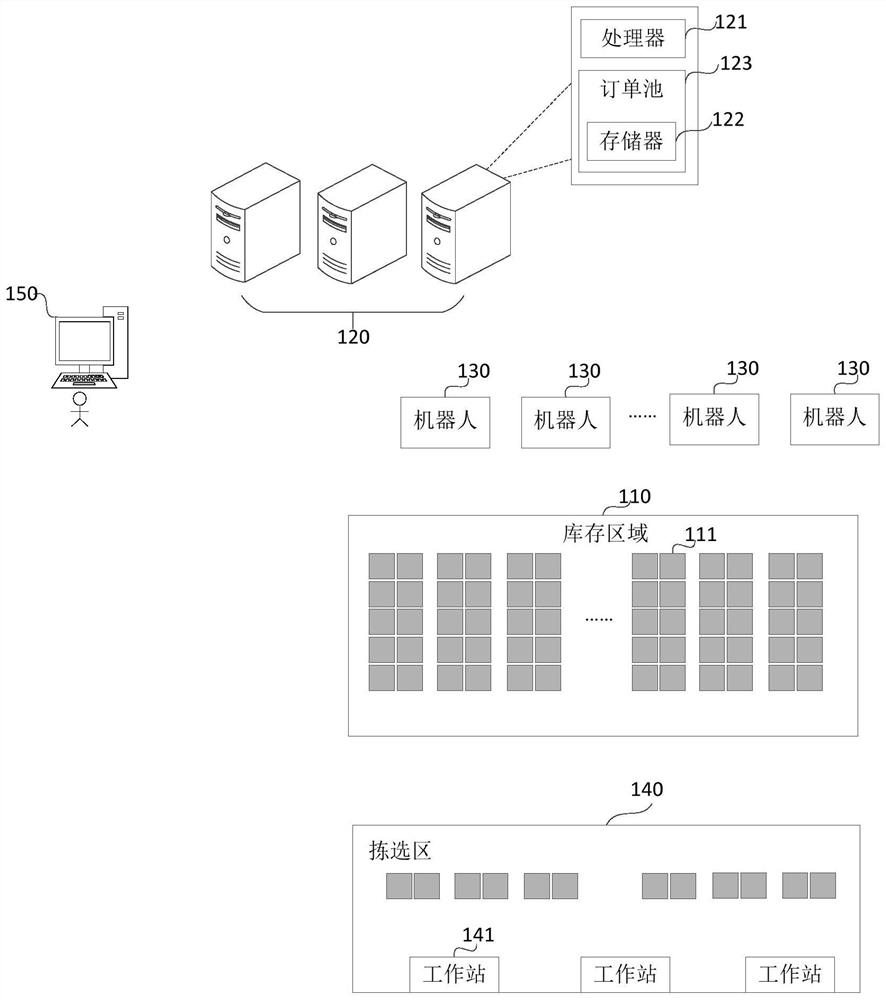

[0041] see figure 1The schematic structural diagram of the storage system shown includes: a storage area 110 , a control server 120 , a robot 130 and a plurality of workstations 141 in the picking area 140 .

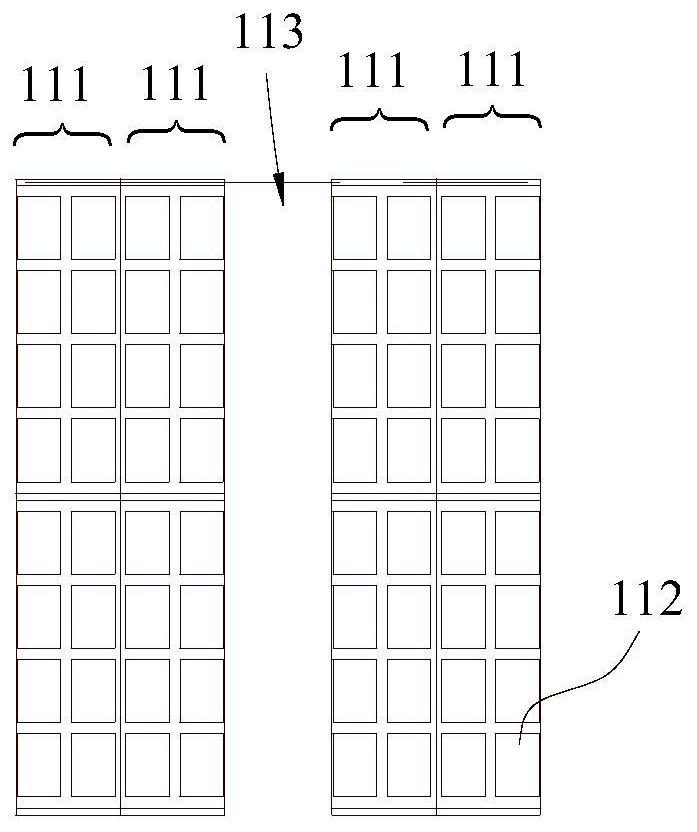

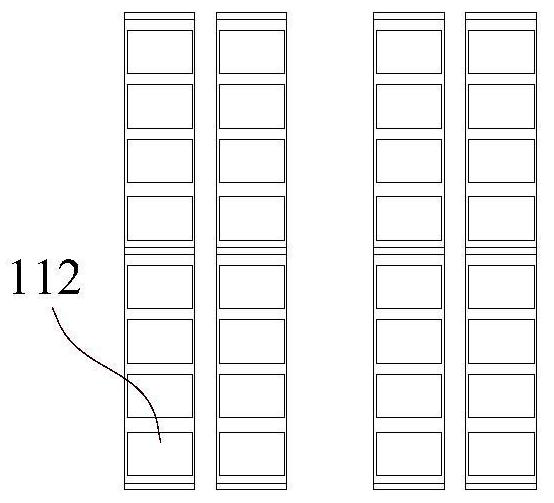

[0042] The inventory area 110 is placed with an inventory support 111, and the inventory support 111 includes at least one layer of laminates, and the at least one layer of laminates separates the inventory support into at least two layers. At least two storage containers 112 are placed in the depth direction, and the width direction of the storage containers 112 on the inventory support 111 is consistent with the depth direction of the laminates.

[0043] The number of storage containers 112 that can be placed along the depth direction on the inventory support 111 can be determined according to actual needs, for example, two storage containers 112 or three storage containers 112 or even more can be placed. The number of storage containers 112 placed in the depth direct...

Embodiment 2

[0063] This embodiment provides a technical solution on the basis of the first embodiment above, and the storage system of this embodiment will be described below.

[0064] The control server 120 is further configured to respond to at least two order tasks, wherein the target storage container corresponding to the first order task in the at least two order tasks is the same as the second order task in the at least two order tasks The target storage container corresponding to the order task is at least one of the two storage containers adjacent to the depth direction of the same layer, and the target workstation, target storage container, and target robot that execute the first order task and the second order task are determined, as the The target robot plans a walking path, and sends control instructions corresponding to the execution of the first order task and the second order task to the target robot.

[0065] The target robot is further configured to, in response to the co...

Embodiment 3

[0073] This embodiment provides a technical solution on the basis of the first embodiment above, and the storage system of this embodiment will be described below.

[0074] The control server 120 is further configured to, in response to the first order task, determine a first target workstation, a first target storage container, and a target robot for executing the first order task, plan a first walking path for the target robot, and send The target robot sends a first control instruction corresponding to the execution of the first order task;

[0075] The target robot 130 is further configured to, in response to the first control instruction, walk to the position of the inventory rack where the target storage container is located according to the planned first walking path, and take out the first target from the inventory rack The storage container and the storage container immediately adjacent to the first target storage container in the depth direction of the laminate of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com