A heavy hammer assembly of a bucket wheel stacker and reclaimer

A bucket wheel stacker-reclaimer and heavy hammer technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problem of unclear connection stability and force of the heavy hammer, unclear specific structure of the heavy hammer, and influence on the force. and balance adjustment, to achieve the effect of good bearing capacity and stability, maintaining force balance, and maintaining dispersed force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

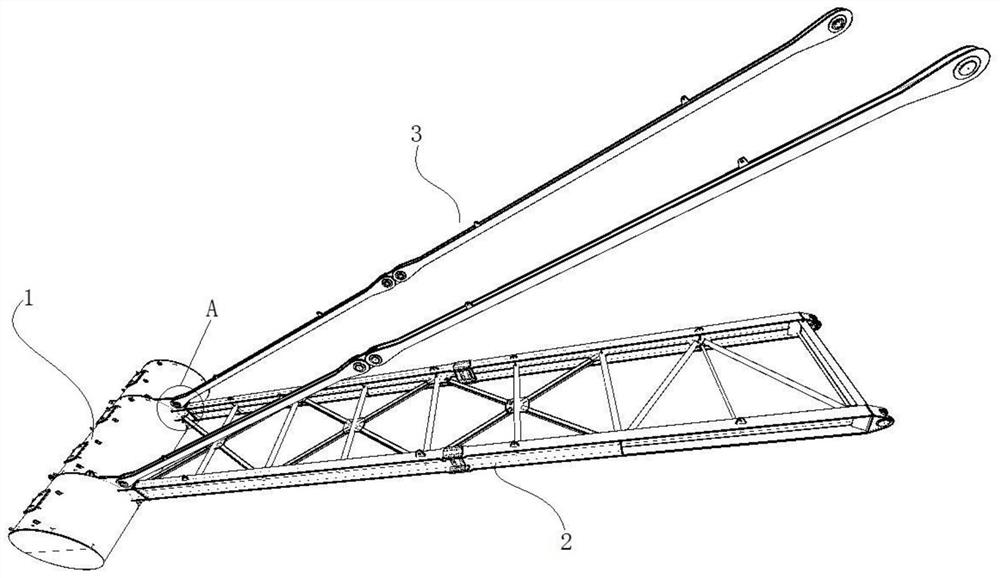

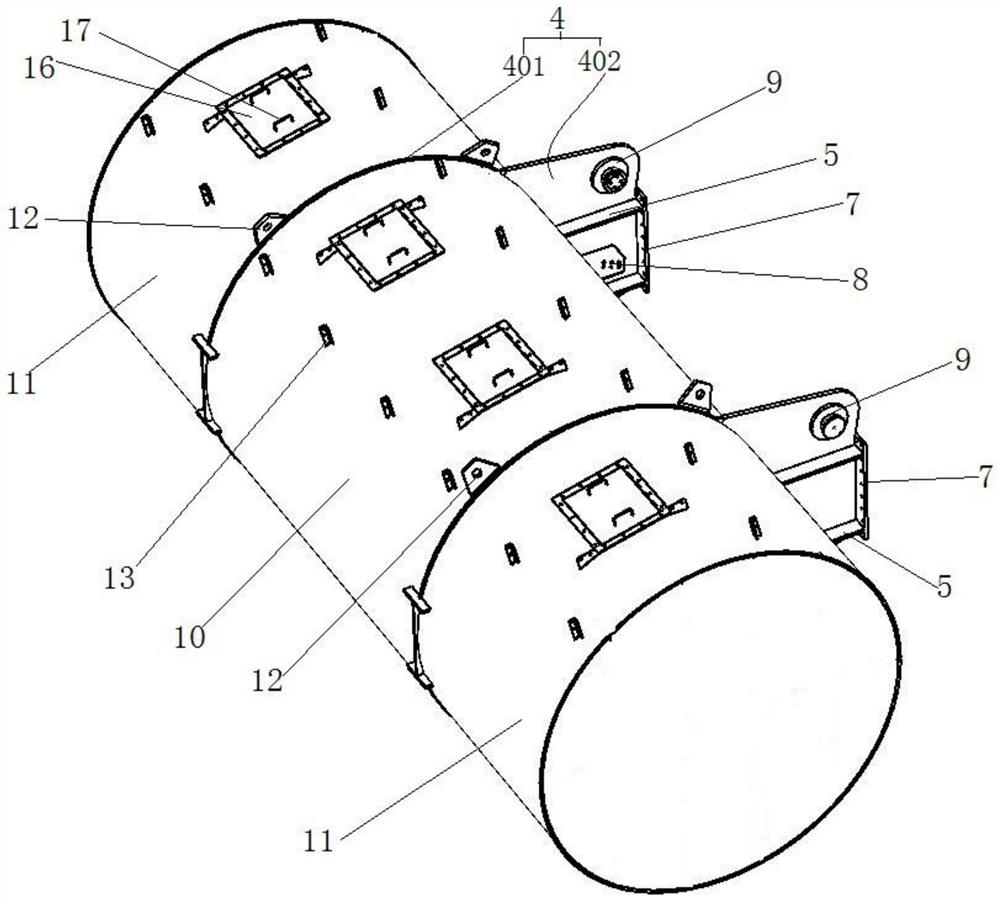

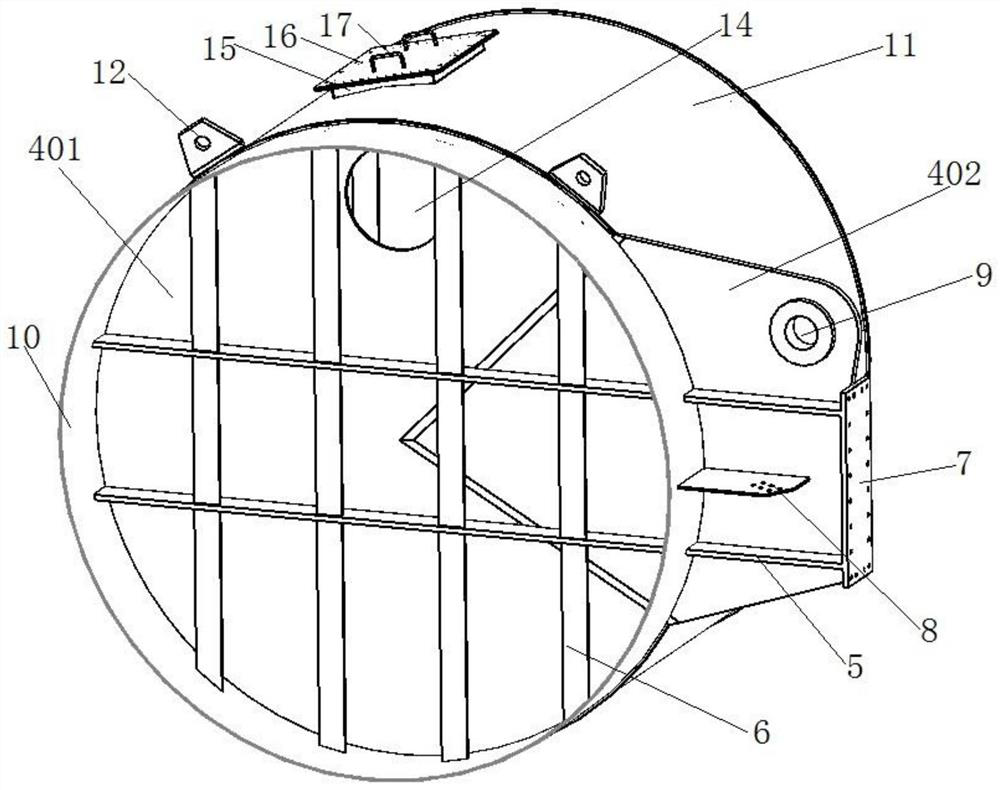

[0040] Such as Figure 1 to Figure 6 As shown, a heavy hammer assembly of a bucket wheel stacker reclaimer, the heavy hammer assembly includes a heavy hammer body 1, and a horizontal cantilever assembly 2 and a diagonal rod assembly 3 connected to the heavy hammer body 1; Hammer body 1 comprises a pair of cantilever plates 4 arranged in parallel, and said cantilever plates 4 have a circular portion 401 and a polygonal portion 402 (special-shaped plates, one side is arc-shaped, and the other sides are polygonal); each said cantilever plate 4 Both sides of the circular part 401 are respectively symmetrically provided with two transverse tie bars 5, and at least one side of the circular part 401 is provided with four vertical tie bars 6, and the end of the polygonal part 402 is provided with the cantilever Plate 4 is vertical to the main mounting plate 7, and the oblique upper corner of the polygonal part 402 is provided with a flange hole 9; a pair of cantilever plates 4 are wel...

Embodiment 2

[0057] This embodiment provides a structure of a horizontal cantilever assembly and a diagonal stay rod assembly.

[0058] Specifically as Figure 7 As shown, the horizontal cantilever assembly 2 includes a pair of main beams 201 arranged in parallel, and a number of parallel cross beams 202 are arranged at equal intervals between the pair of main beams 201, and the two ends of the cross beams 202 are respectively connected to the The inner side of the main beam 201 is fixed by cross welding; the middle part of the cross beam 202 is horizontally provided with a middle connecting plate 203, and the four corners of the middle connecting plate 203 are respectively screwed with section steel 204, and the other ends of the section steel 204 are respectively screw connected to On the main beam 201 on the corresponding side, every four of the section steels 204 and one of the middle connecting plates 203 form an "X"-shaped fixed structure; Figure 6 As shown, the end of the main bea...

Embodiment 3

[0064] This embodiment provides a structure in which the weight hammer assembly of the first embodiment is installed on the bucket wheel stacker and reclaimer.

[0065] Such as Figure 8 As shown, the ends of the horizontal cantilever assembly 2 and the inclined rod assembly 3 away from the weight body 1 are respectively hinged and fixed on the main tower 18, and the other side of the main tower 18 is respectively connected with a bucket wheel connection cantilever 19 and The bucket wheel is connected to the cantilever inclined rod 20; the vertical height of the horizontal cantilever assembly 2 is set higher than the height of the bucket wheel connected to the cantilever 19, and the vertical height of the weight body 1 is higher than the height of the wheel bucket 21.

[0066] The arrangement of this structure facilitates the adjustment of the pitch angle of the wheel bucket, and the weight body 1 can maintain the force balance of the main tower 18 under different angles and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com