Polyester resin with excellent wear resistance and chemical resistance for powder and preparation method of polyester resin

A polyester resin and chemical resistance technology, used in powder coatings, polyester coatings, coatings, etc., can solve the problem of further improvement in wear resistance, and achieve improved chemical resistance and chemical resistance. Excellent, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

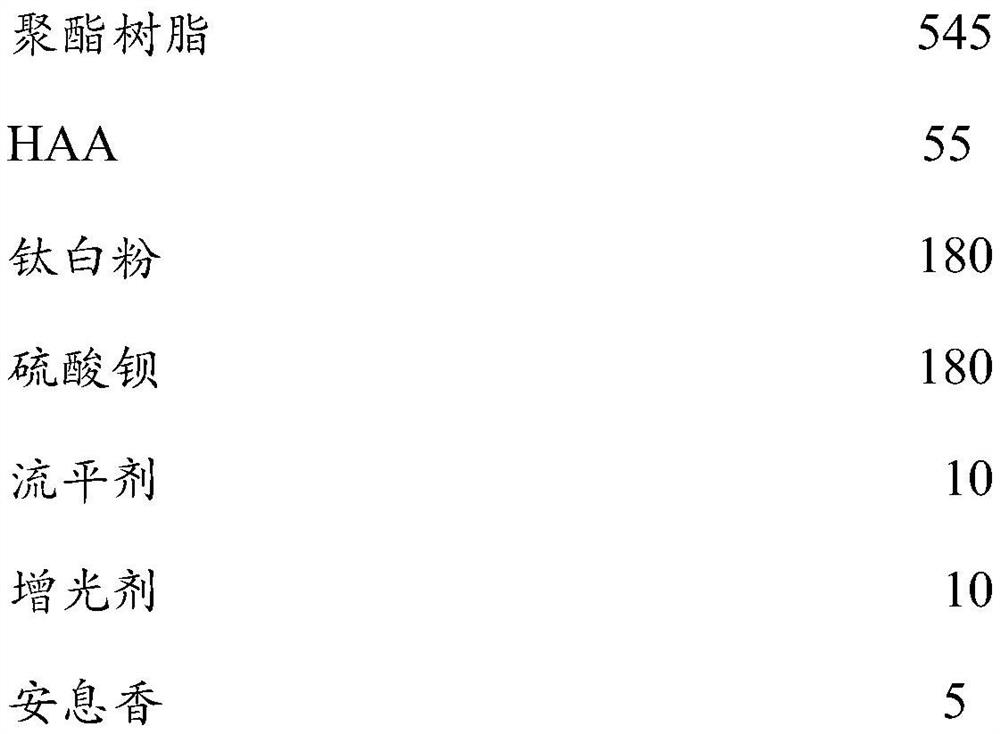

Embodiment 1

[0060] A method for preparing a polyester resin for powder with excellent wear resistance and chemical resistance, comprising the following steps:

[0061] (1) Add N,N-dimethylacetamide and catalyst triisobutylaluminum into the reactor, start stirring and mix evenly, raise the temperature to 80°C and keep it warm, and feed nitrogen into the reactor, and then gradually drop Add 3,3-bis(chloromethyl)oxetane to carry out the polymerization reaction of small molecule chlorinated polyether, control the dripping within 3.5h, and then continue the heat preservation reaction for 3h;

[0062] (2) Add neopentyl glycol diglycidyl ether to the material in step (1) to participate in the copolymerization reaction, gradually raise the temperature from 80°C to 140°C at a heating rate of 10°C / h, and keep the temperature for 3h;

[0063] (3) when the epoxy equivalent of the mixture is greater than 1000g / mol, add neopentyl glycol, terephthalic acid, 1,4-naphthalene dicarboxylic acid and esterifi...

Embodiment 2

[0067] A method for preparing a polyester resin for powder with excellent wear resistance and chemical resistance, comprising the following steps:

[0068] (1) Add N,N-dimethylacetamide and catalyst triisobutylaluminum into the reactor, start stirring and mix evenly, raise the temperature to 70°C and keep it warm, and feed nitrogen into the reactor, and then gradually drop Add 3,3-bis(chloromethyl)oxetane to carry out the polymerization reaction of small molecule chlorinated polyether, control the dripping within 3 hours, and then continue the heat preservation reaction for 2.5 hours;

[0069] (2) Add neopentyl glycol diglycidyl ether to the material in step (1) to participate in the copolymerization reaction, gradually raise the temperature from 70°C to 130°C at a heating rate of 8°C / h, and keep the temperature for 2h;

[0070] (3) when the epoxy equivalent of the mixture is greater than 1000g / mol, add neopentyl glycol, terephthalic acid, 1,4-naphthalene dicarboxylic acid and...

Embodiment 3

[0074] A method for preparing a polyester resin for powder with excellent wear resistance and chemical resistance, comprising the following steps:

[0075] (1) Add N,N-dimethylacetamide and catalyst triisobutylaluminum into the reactor, start stirring and mix evenly, raise the temperature to 90°C and keep it warm, and feed nitrogen into the reactor, and then gradually drop Add 3,3-bis(chloromethyl)oxetane to carry out the polymerization reaction of small molecule chlorinated polyether, control the dripping within 4 hours, and then continue the heat preservation reaction for 3.5 hours;

[0076] (2) Add neopentyl glycol diglycidyl ether to the material in step (1) to participate in the copolymerization reaction, gradually raise the temperature from 90°C to 150°C at a heating rate of 12°C / h, and keep the temperature for 4h;

[0077] (3) when the epoxy equivalent of the mixture is greater than 1000g / mol, add neopentyl glycol, terephthalic acid, 1,4-naphthalene dicarboxylic acid an...

PUM

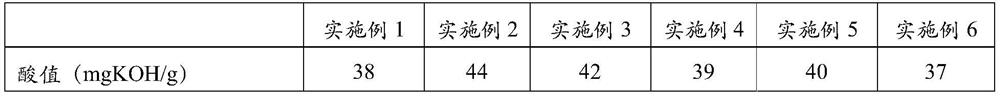

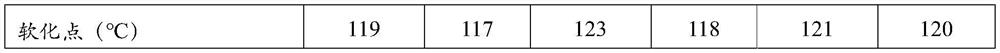

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com