A gasification furnace pretreatment and feeding system

A feeding system and pretreatment technology, which is applied to the feeding tool of gasification device, gasification process, molten salt/molten metal gasification, etc., to achieve the effect of convenient and firm installation, avoiding leakage of gaps and protecting production personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0057] Combine below Figure 1 to Figure 19 The present invention will be described in detail.

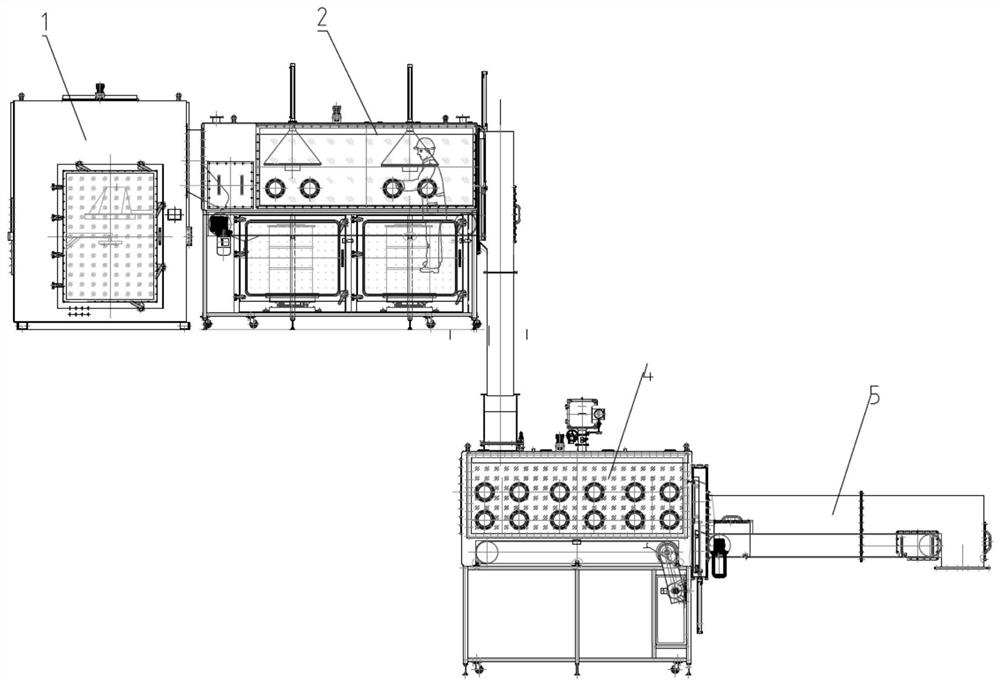

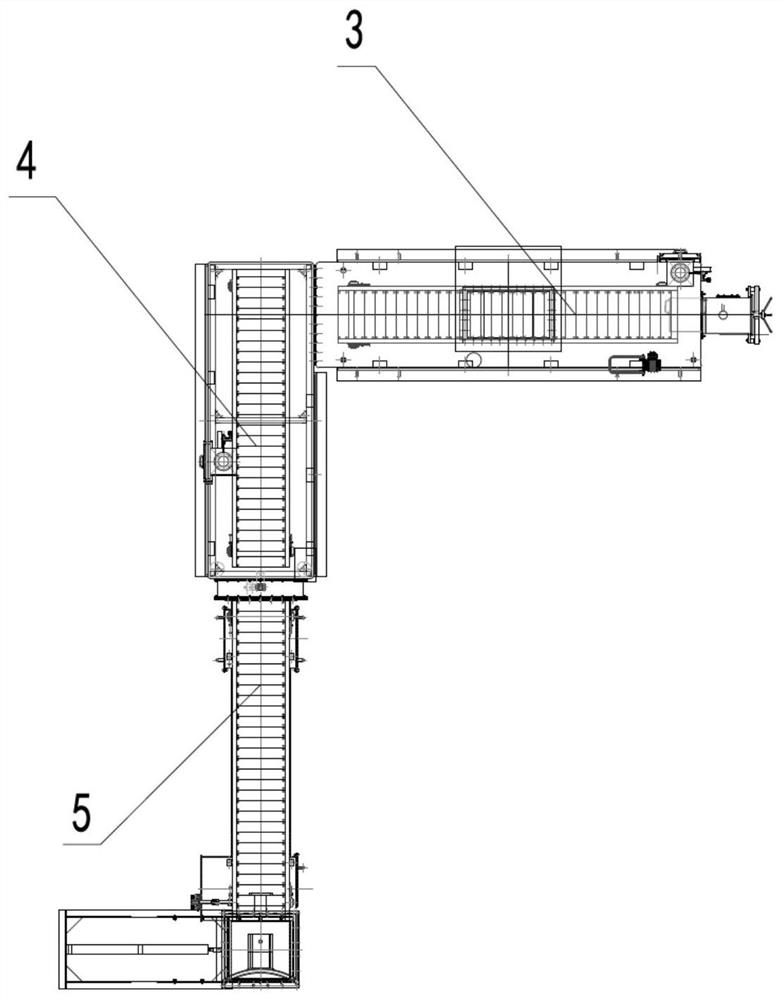

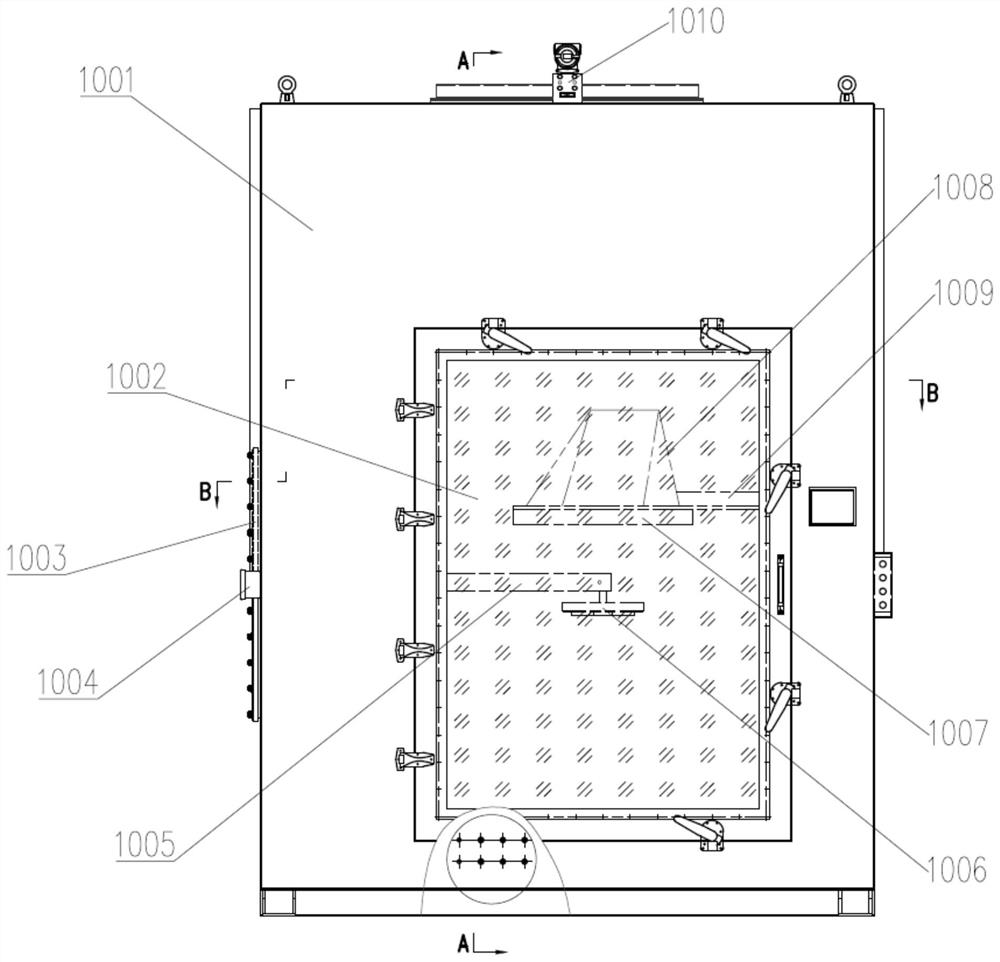

[0058] A gasification furnace pretreatment and feeding system, including a built-in sealing and uncapping device 1, a sorting glove box 2 and a packing glove box 3 connected in sequence, between the built-in sealing and uncapping device 1 and the sorting glove box 2 Separated by the pneumatic isolation door I1026, the outlet of the sorting glove box 2 is communicated with the inlet of the packing glove box 3 through the chute 2009. A pneumatic isolation door II 2005 is set between the sorting glove box 2 and the walking pipe 2009. As a preferred solution, the outlet end of the packing glove box 3 is sequentially connected with a temporary storage glove box 4 and a feeding mechanism 5 .

[0059] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com