Heat balance and heat recovery system for ground-source heat pump

A ground source heat pump and heat balance technology, applied in geothermal energy systems, heating systems, hot water central heating systems, etc., can solve the problems of inability to recycle circulating water heat, inability to save underground cold and heat balance, etc., and improve operating efficiency , Reduce energy consumption and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

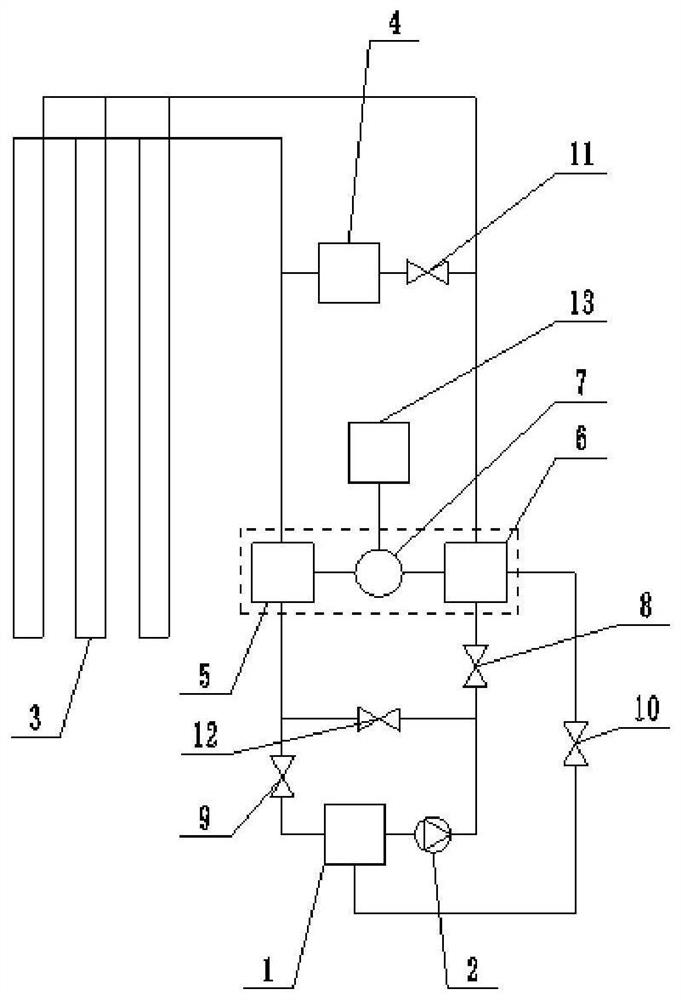

[0025] In this embodiment, a ground source heat pump heat balance and heat recovery system, such as figure 1 As shown, it includes heat pump host 1, circulating water pump 2, buried pipe 3, energy tower heat pump 4, cold water tank 5, hot water tank 6 and thermoelectric generator 7, above-mentioned heat pump host 1, circulating water pump 2, hot water tank 6, The buried pipe 3 and the hot water tank 6 are sequentially connected to form a first circuit, the heat pump host 1, the circulating water pump 2, the cold water tank 5, the buried pipe 3 and the hot water tank 6 are connected in sequence to form a second circuit, and the energy tower heat pump 4 One end is connected between the above-mentioned buried pipe 3 and the above-mentioned hot water tank 6 and the other end is connected between the above-mentioned buried pipe 3 and the above-mentioned cold water tank 5. The above-mentioned energy tower heat pump 4 can heat in winter and cool in summer. The generator 7 is connecte...

Embodiment 2

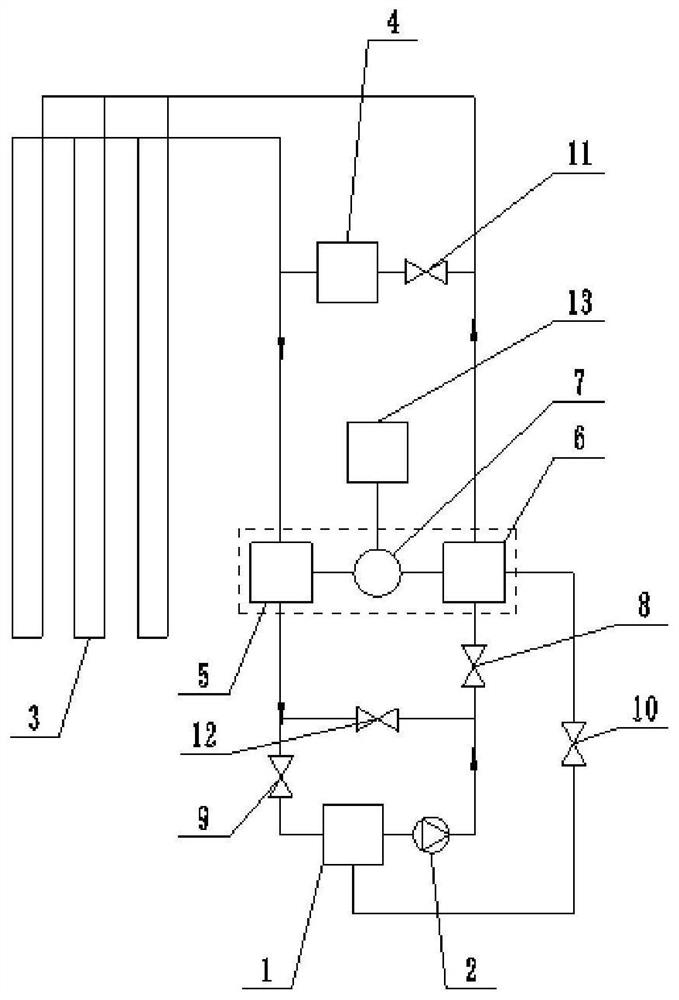

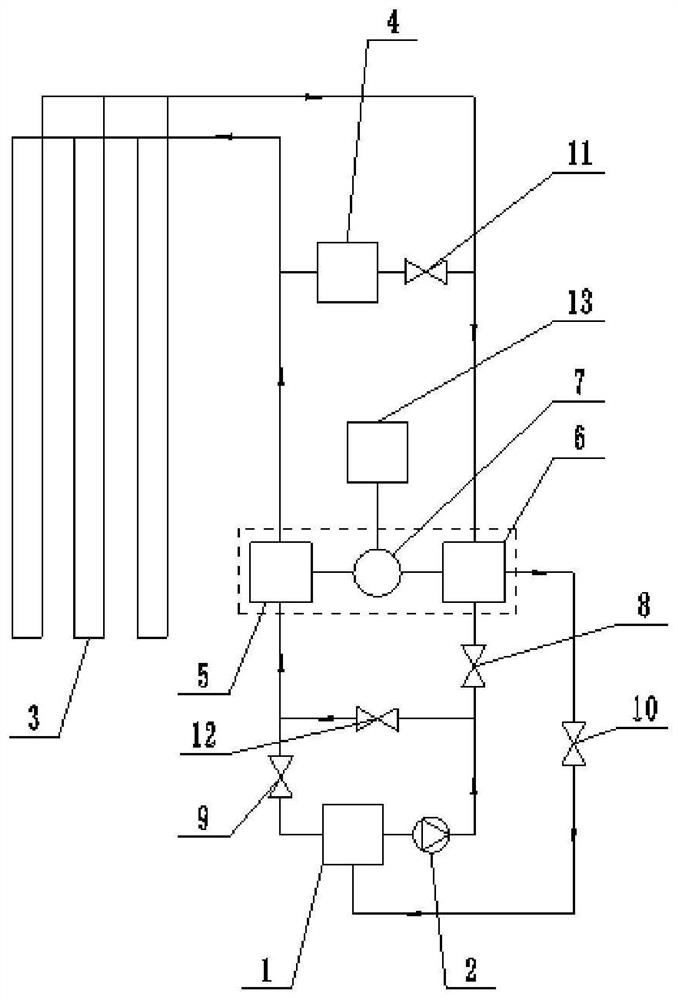

[0028] This embodiment is further optimized on the basis of Embodiment 1. In this embodiment, as figure 1 As shown, a first valve 8 is provided between the above-mentioned circulating water pump 2 and the above-mentioned hot water tank 6, a second valve 9 is provided between the above-mentioned heat pump main unit 1 and the above-mentioned cold water tank 5, and the above-mentioned heat pump main unit 1 and the above-mentioned hot water tank 6 A third valve 10 is provided between them, and a fourth valve 11 is provided on the outlet pipe of the above-mentioned energy tower heat pump 4, and a fifth valve 12 is also included. The water inlet end of the above-mentioned fifth valve 12 is connected between the above-mentioned circulating water pump 2 and the first Between the valves 8, the water outlet of the above-mentioned fifth valve 12 is connected between the above-mentioned cold water tank 5 and the second valve 9. With this structure, in summer, if figure 2 As shown, open t...

Embodiment 3

[0032]This embodiment is further optimized on the basis of Embodiment 2. In this embodiment, the above-mentioned thermoelectric generator 7 is provided with a heat conduction sheet and a cold conduction sheet, and the hot surface end of the above-mentioned thermoelectric generator 7 passes through the above-mentioned heat conduction sheet and the above-mentioned hot water. The tank 6 is connected, and the cold side end of the above-mentioned thermoelectric generator 7 is connected with the above-mentioned cold water tank 5 through the above-mentioned cold guide plate. The power generation principle of the above-mentioned thermoelectric generator 7 is the prior art, so it will not be repeated here.

[0033] In this embodiment, a storage battery 13 is also included, and the storage battery 13 is electrically connected to the output end of the thermoelectric generator 7 so as to store the generated direct current.

[0034] Further, an inverter is also included, the inverter is ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com