Experimental device and experimental method for researching behavior of boiling bubbles in pit under severe accidents

A technology for serious accidents and experimental devices, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems that cannot be simulated by aerosol decay heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

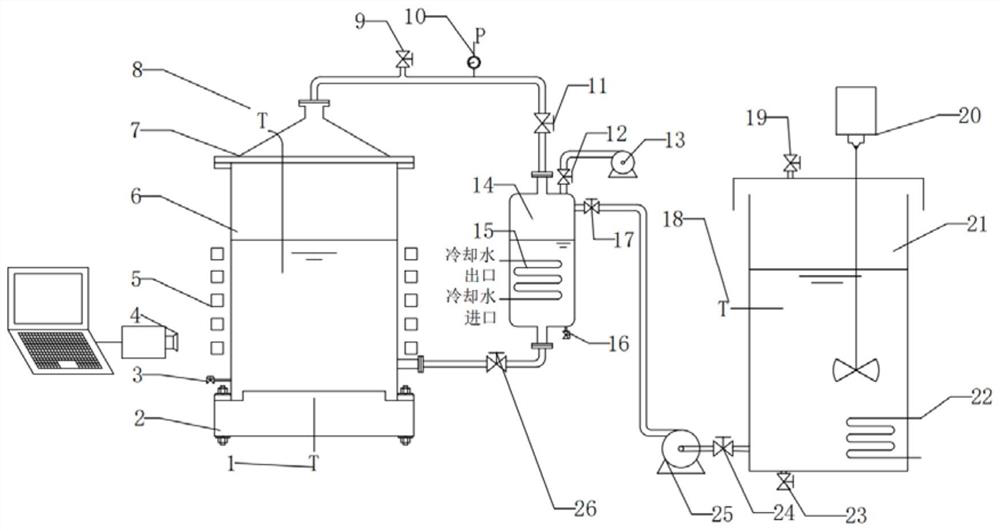

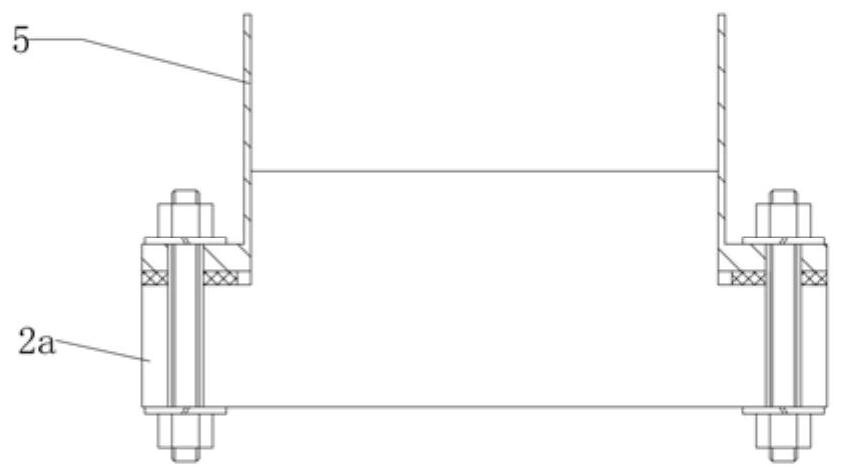

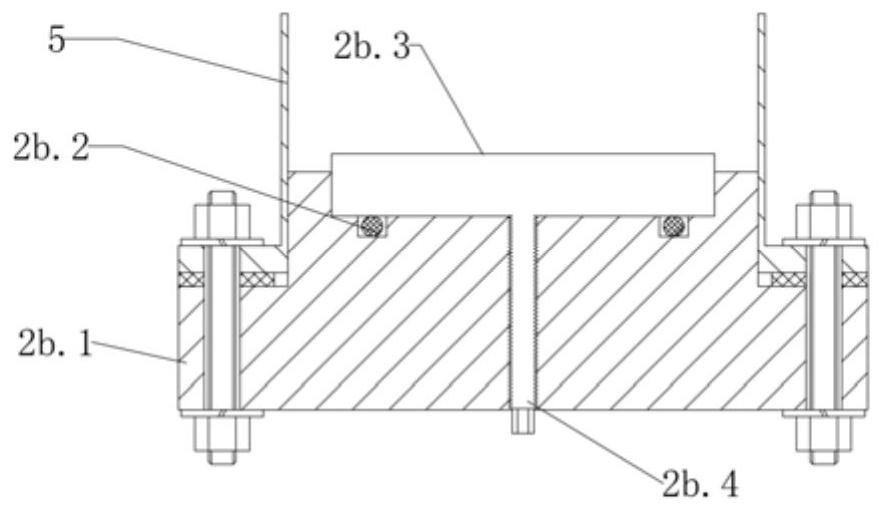

[0023] combine Figure 1-3 , the present invention provides an experimental device for simulating the behavior of boiling bubbles in pits after accidents, the device consists of main body boiling test sections 2, 3, 5, 6, 7, condensation sections 12, 13, 14, 15, 16, 17, solution The preparation sections 19, 20, 21, 22, 23, 24, 25 and connecting pipelines are composed of solenoid valves 9, 11, 26 and pressure sensors 10 in relevant parts of the pipelines, and temperature measuring points 1, 8, 18 are arranged in different positions and connected with The acquisition system is connected, and a high-speed camera 4 is installed outside the device for photographing bubble behavior. The basic principle of the experimental device is as follows: magnetic nanoparticles are dissolved in the boiling test section, and the particles are affected by the changing magnetic field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com