Power distribution cabinet protection structure with high safety

A protective structure and power distribution cabinet technology, which is applied in substation/power distribution device casing, electrical components, substation/switch layout details, etc., can solve problems such as low safety, people's injury, and damage to electrical components inside the power distribution cabinet. Achieve high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

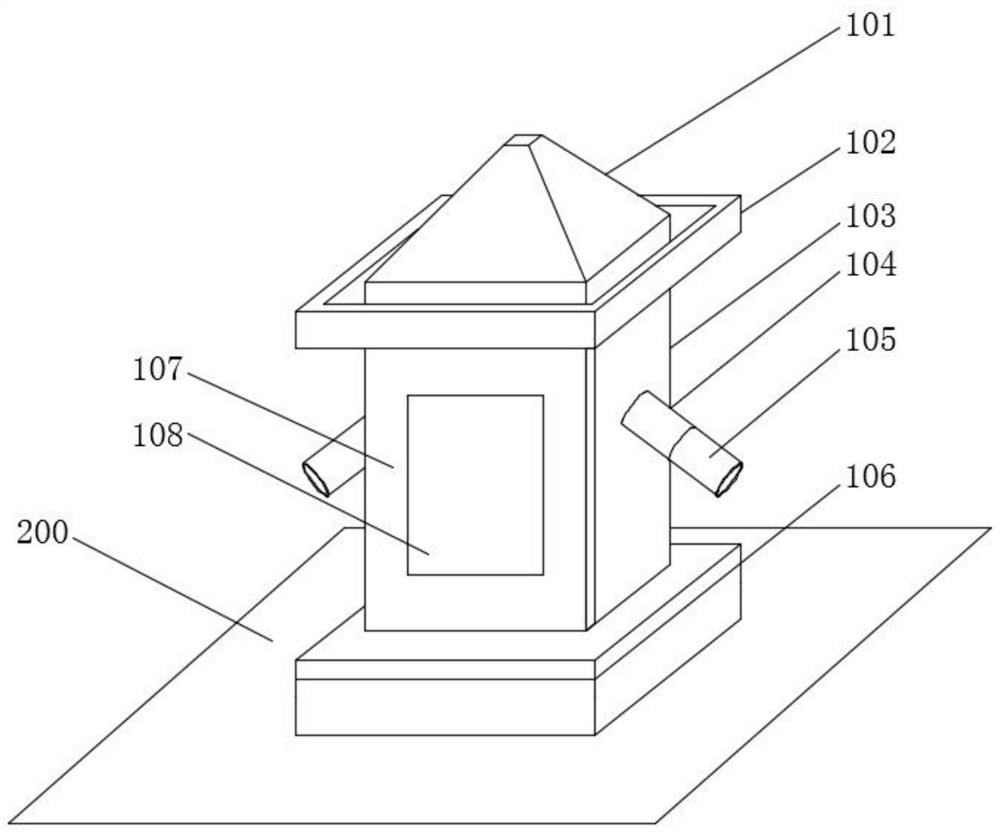

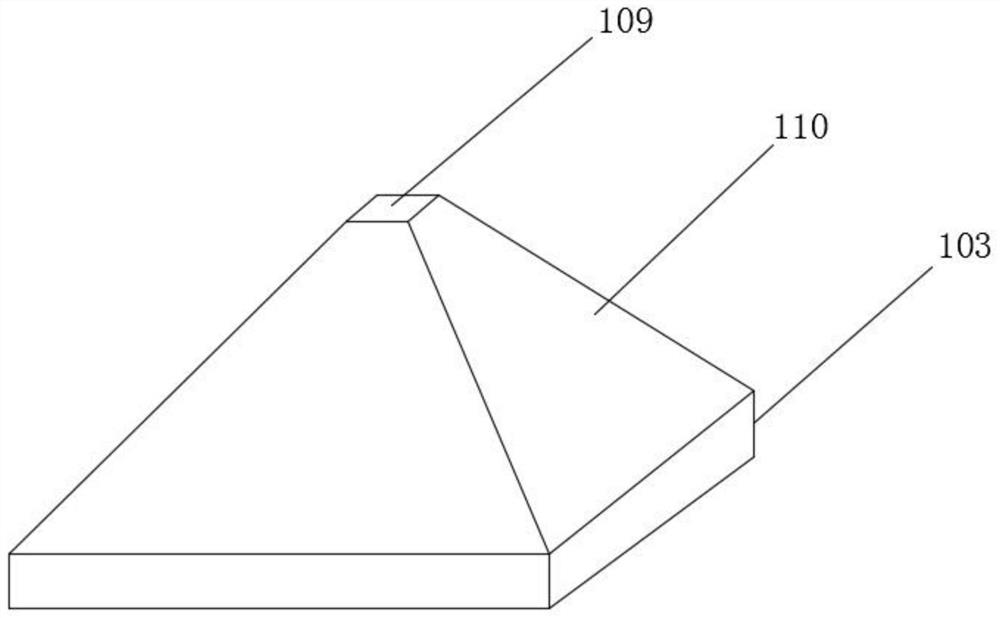

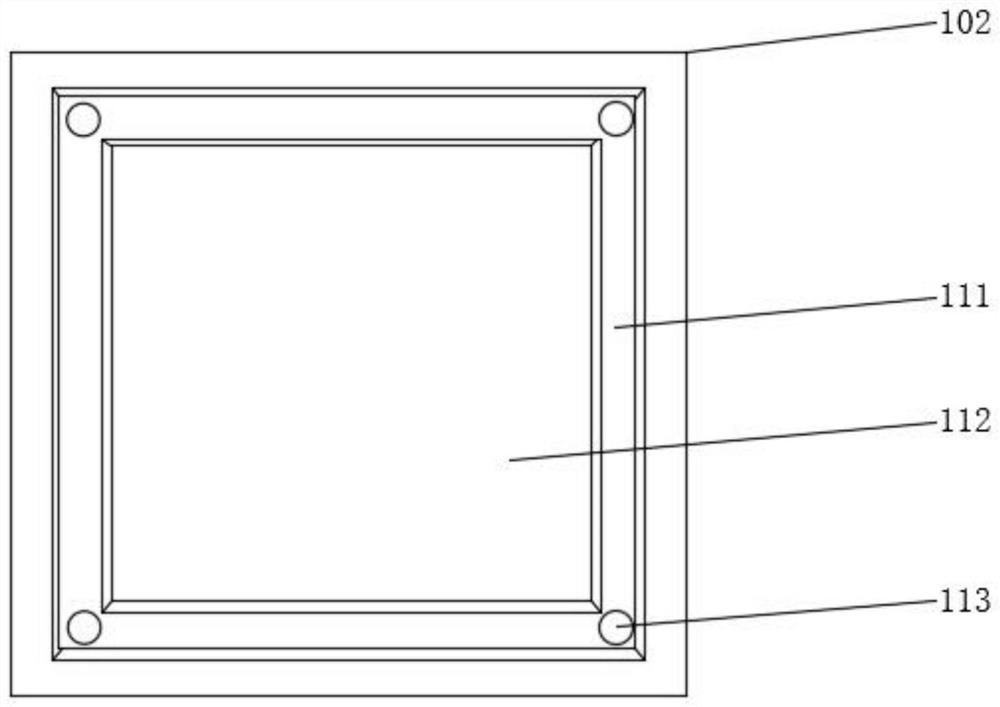

[0048] see Figure 1-9 As shown, this embodiment is a high-safety protection structure for a power distribution cabinet, including an anti-spray cap 101, a protective box 103, and a load-bearing base 106. The top of the protective box 103 is equipped with an anti-spray cap 101, and the protective box A water guide frame 102 is installed outside the top of the body 103. The protective box 103 is installed on the top of the load-bearing base 106. The load-bearing base 106 is installed on the ground 200. Both sides of the protective box 103 are obliquely installed with ventilation pipes 104, and the ventilation pipes 104 The bottom end is connected with a dust-proof pipe 105, and a protective box door 107 is installed on one side of the protective box body 103, and a protective box door 107 is provided with an observation port 108 equipped with tempered glass;

[0049] A heating layer 125 is provided on the inner wall of the protective box 103, and a heating wire is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com