Assembling method of micro module, micro module and FPC module

An assembly method and module technology, which can be applied to devices that apply liquid to the surface, parts of color TVs, image reproducers using projection devices, etc., can solve difficult positioning, low assembly accuracy, low assembly efficiency, etc. problem, to achieve the effect of easy operation, clear adjustment and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

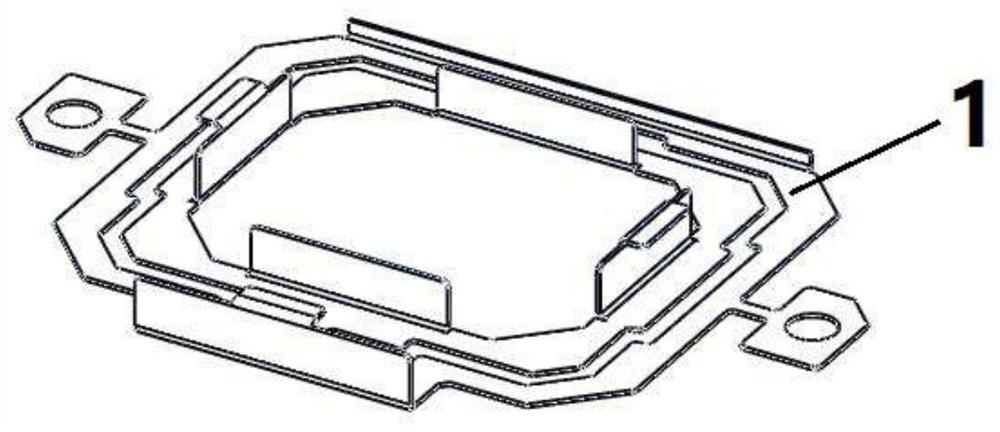

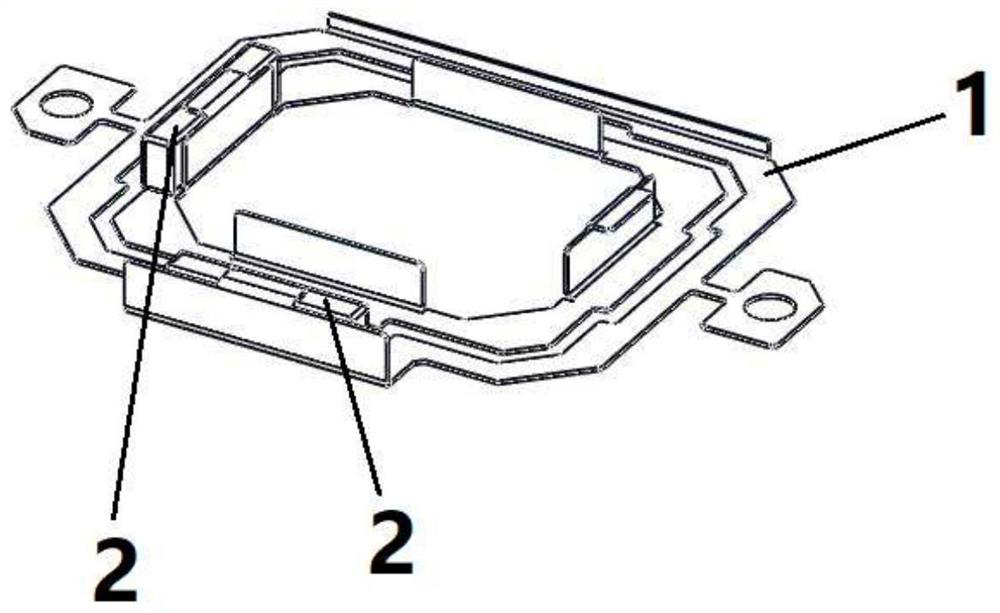

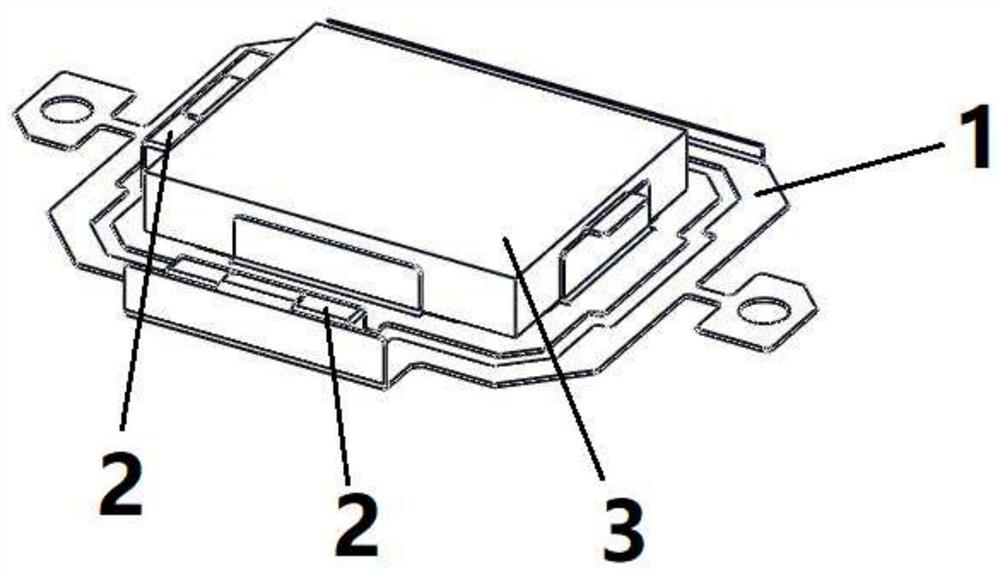

[0037] as attached Figure 1~9 As shown in the figure, it is a flow chart of steps and a schematic diagram of the assembly components of a micro-module assembly method provided by an embodiment of the present invention. The assembly method includes the following steps:

[0038] S101, assembling the magnet 2 into the shrapnel 1;

[0039] S102, assembling the optical filter 3 into the shrapnel 1;

[0040] S103, dispensing glue 6 on the contact parts of the magnet 2, the optical filter 3 and the shrapnel 1, the glue 6 is UV glue epoxy glue, and the first semi-finished product is obtained after the glue 6 is solidified;

[0041] S104, assembling the coil 5 into the fixing frame 4, dispensing glue 6 at the contact position between the coil 5 and the fixing piece, the glue 6 is UV glue epoxy glue, and the second semi-finished product is obtained after the glue 6 is solidified;

[0042] S105, assembling the first semi-finished product into the second semi-finished product, dispensi...

Embodiment 2

[0044] as attached Figure 1~9 As shown in the figure, it is a flow chart of steps and a schematic diagram of the assembly components of a micro-module assembly method provided by an embodiment of the present invention. The assembly method includes the following steps:

[0045] S101, assembling the magnet 2 into the shrapnel 1;

[0046] S102, assembling the optical filter 3 into the shrapnel 1;

[0047] S103, dispensing glue 6 on the contact parts of the magnet 2, the optical filter 3 and the shrapnel 1, the glue 6 is organic silica gel, and the first semi-finished product is obtained after the glue 6 is solidified;

[0048] S104, assembling the coil 5 into the fixing frame 4, dispensing glue 6 on the contact part between the coil 5 and the fixing piece, the glue 6 is organic silica gel, and the second semi-finished product is obtained after the glue 6 is solidified;

[0049] S105, assembling the first semi-finished product into the second semi-finished product, dispensing g...

Embodiment 3

[0051] as attached Figure 7~9 As shown in the figure, it is a flow chart of steps and a schematic diagram of the assembly components of a micro-module assembly method provided by an embodiment of the present invention. The assembly method includes the following steps:

[0052] S101, assembling the magnet 2 into the shrapnel 1;

[0053] S102, assembling the optical filter 3 into the shrapnel 1;

[0054] S103, dispensing glue 6 on the contact parts of the magnet 2, the optical filter 3 and the shrapnel 1, the glue 6 is room temperature vulcanized silicone rubber, and the first semi-finished product is obtained after the glue 6 is solidified;

[0055] S104, assembling the coil 5 into the fixing frame 4, dispensing glue 6 on the contact part between the coil 5 and the fixing piece, the glue 6 is room temperature vulcanized silicone rubber, and the second semi-finished product is obtained after the glue 6 is solidified;

[0056] S105, assembling the first semi-finished product i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com